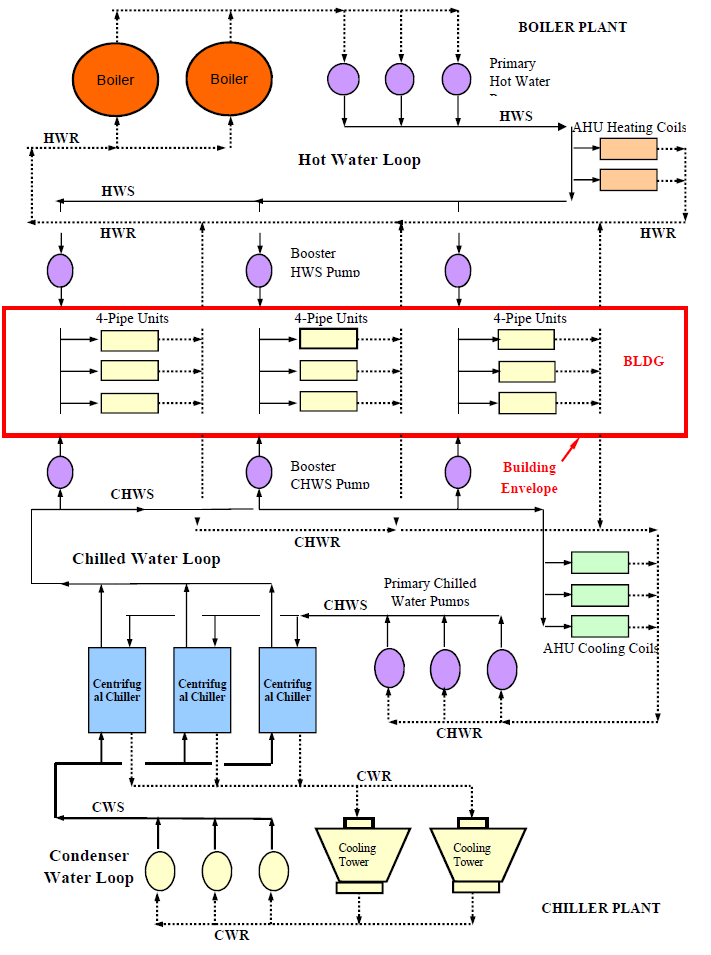

Pipe Sizing Charts Tables

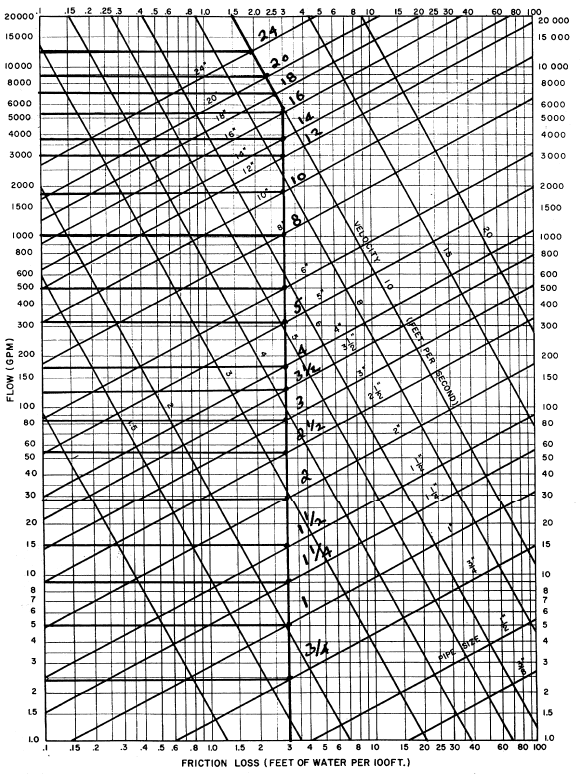

CLOSED SYSTEMS

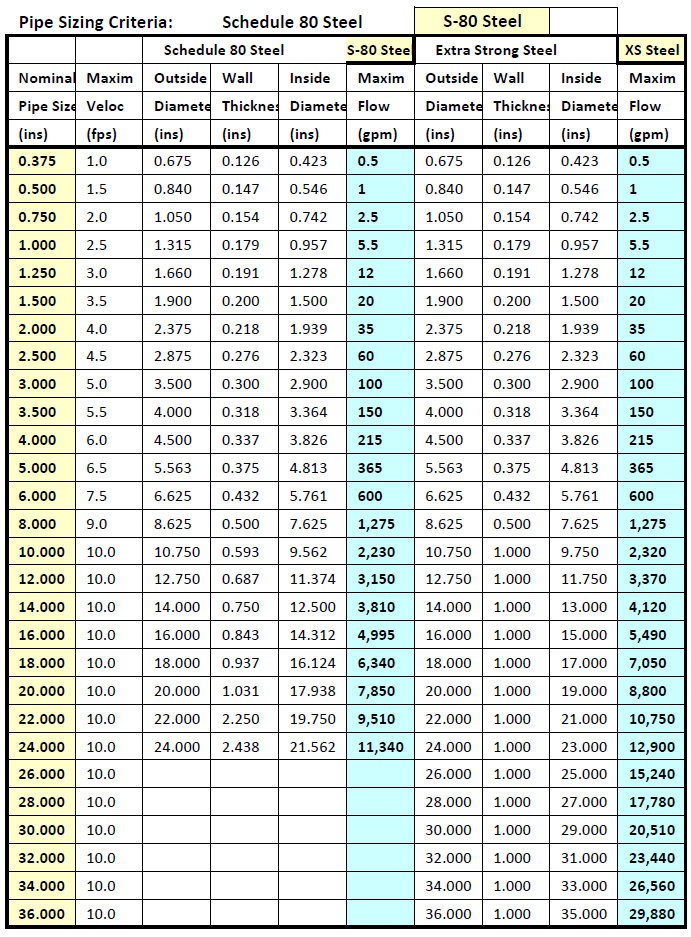

Design Criteria: 3' Frictional Pressure Drop per 100' Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 1 Friction Loss for CLOSED Piping Systems: Schedule 40 Steel Source: Carrier Systems Design

OPEN SYSTEMS

Design Criteria: 3' Frictional Pressure Drop per 100' Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 2 Friction Loss for OPEN Piping Systems: Schedule 40 Steel Source: Carrier Systems Design

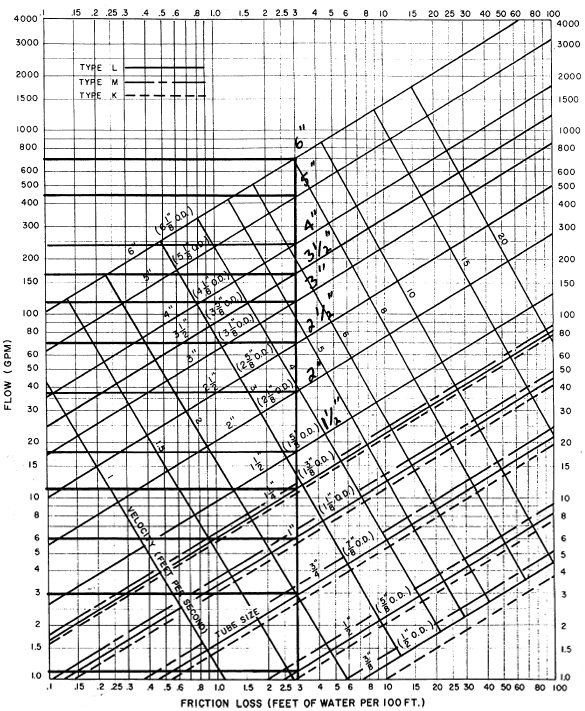

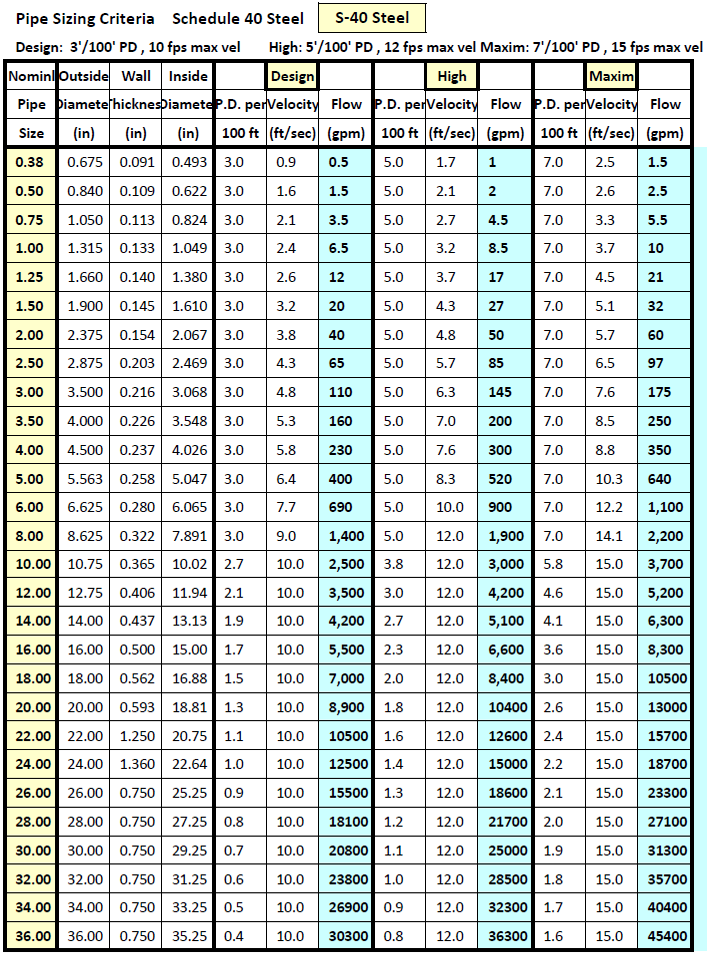

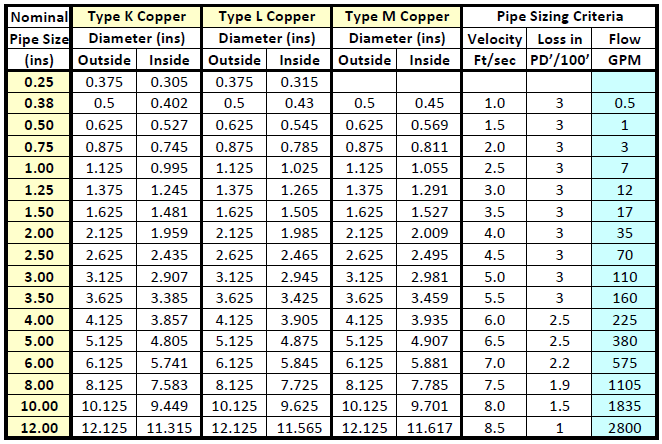

COPPER Physical Dimensions and Sizing Criteria (ASPE Data Book)

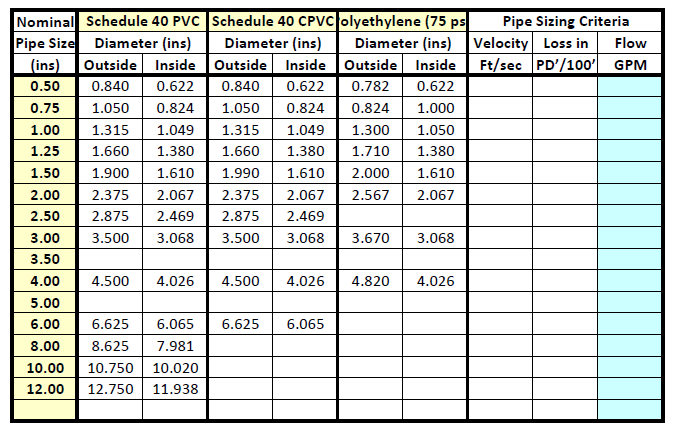

PLASTIC Physical Dimensions and Sizing Criteria (ASPE Data Book)

Copper Pipe Sizing Chart

Design Criteria: 3' Frictional Pressure Drop per 100' Pipe Length with a Maximum Velocity of 10 ft/sec

Figure - 3 Friction Loss for Copper Piping Systems: Types K, L, & M Source: Carrier Systems Design

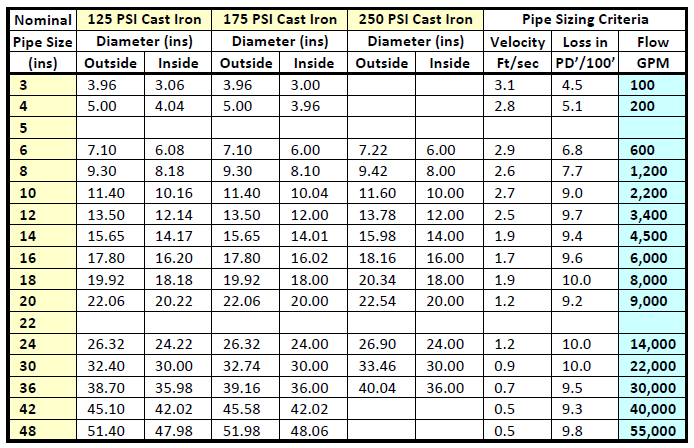

CAST IRON Physical Data Hydraulic Handbook Colt Industries

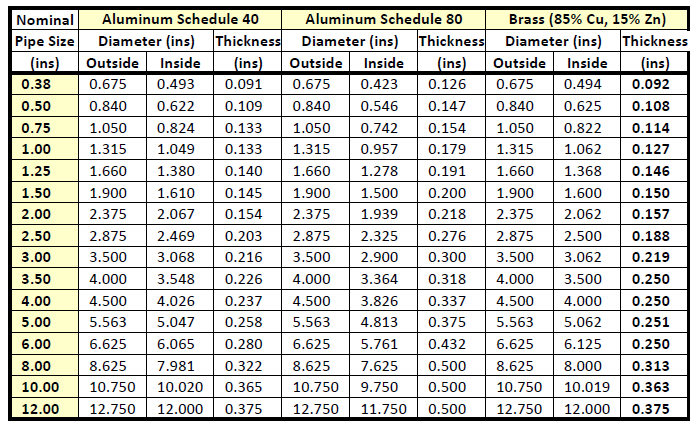

ALUMINUM , BRASS Handbook for Mechanical Engineers : Baumeister & Marks

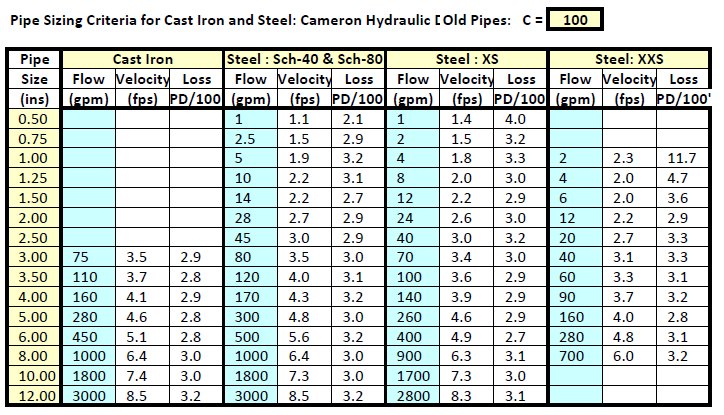

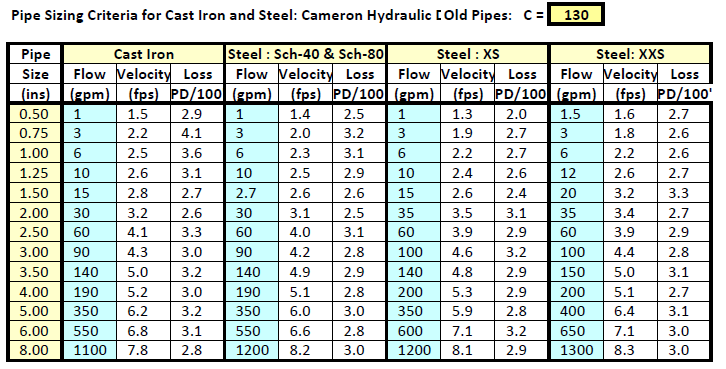

PIPE DESIGN BASED ON HAZEN WILLIAMS FORM(UfL=A0.2083 x (100/C)^1.85 x Q^1.85/D^4.8635 )

Source: Cameron Hydraulic Data, 1926-62

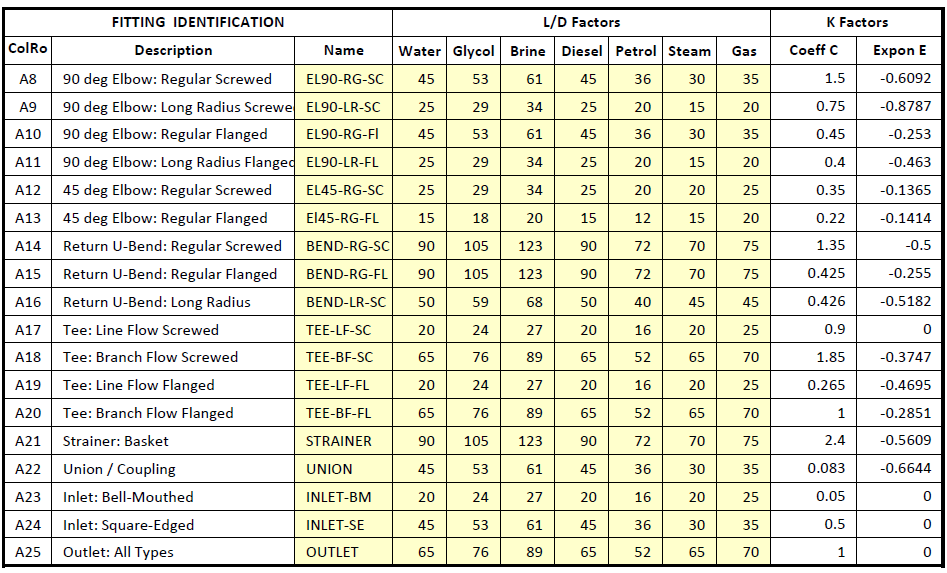

Dynamic Pressure Losses through Fittings

EL = L/D* D (EL = Equivalent Length. L=Pipe Length, D = Pipe Diameter)

Velocity Pressure Factor (K) forWater : K = C*D**E: Pressure Drop (PD) = K*VP

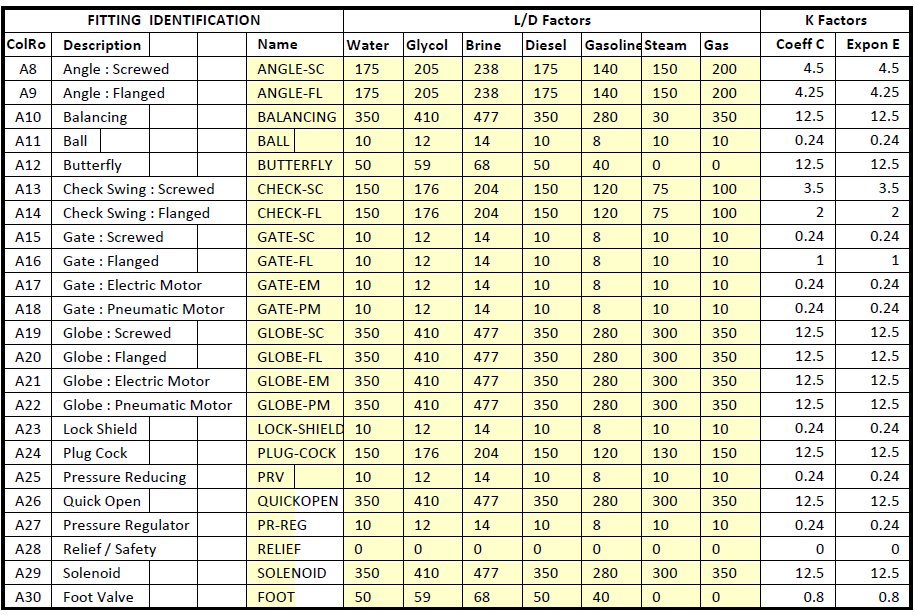

Dynamic Pressure Losses through Valves

EL = L/D* D (EL = Equivalent Length. L=Pipe Length, D = Pipe Diameter)

Velocity Pressure Factor (K) forWater : K = C*D**E: Pressure Drop (PD) = K*VP

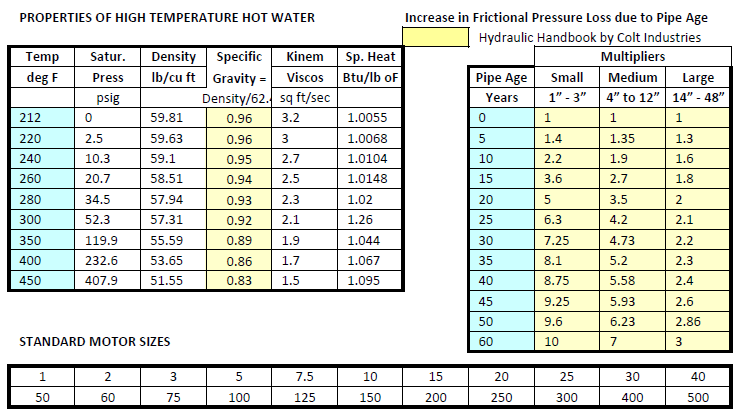

PROPERTIES OF LIQUIDS

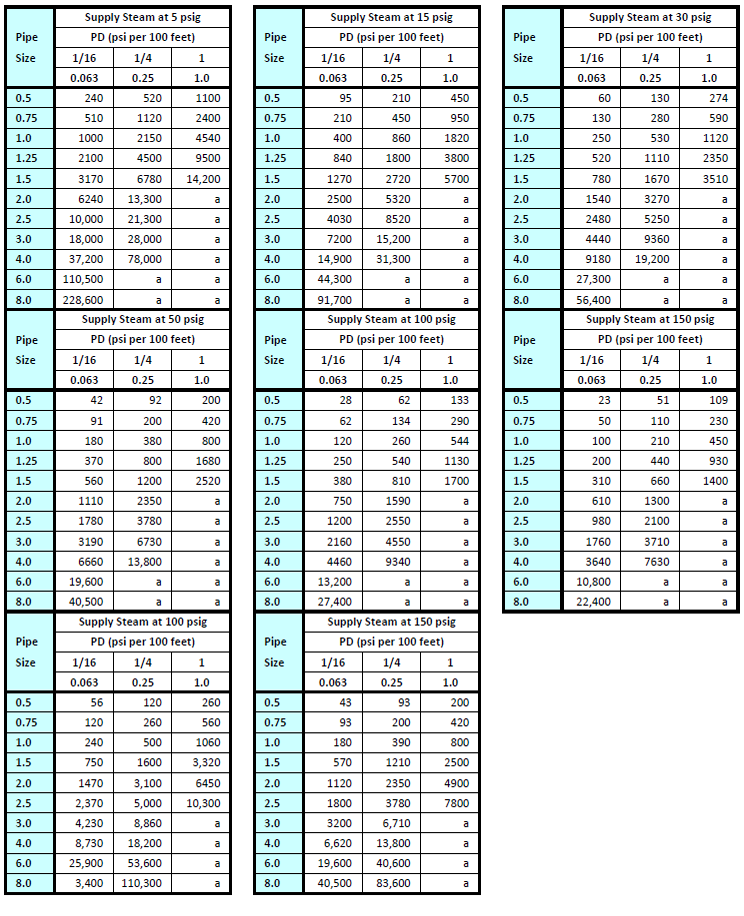

STEAM PRESSURE CLASSIFICATION AND PIPE SIZING DESIGN CRITERIA

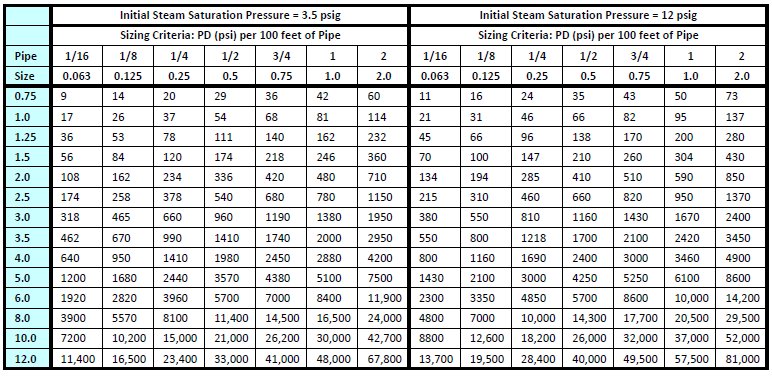

LOW PRESSURE STEAMPIPE SIZING CRITERIA : Flow Rates of Steam (lbs/hr)

MEDIUM PRESSURE STEAM PIPE SIZING CRITERIA : Flow Rates of Steam (lbs/hr)

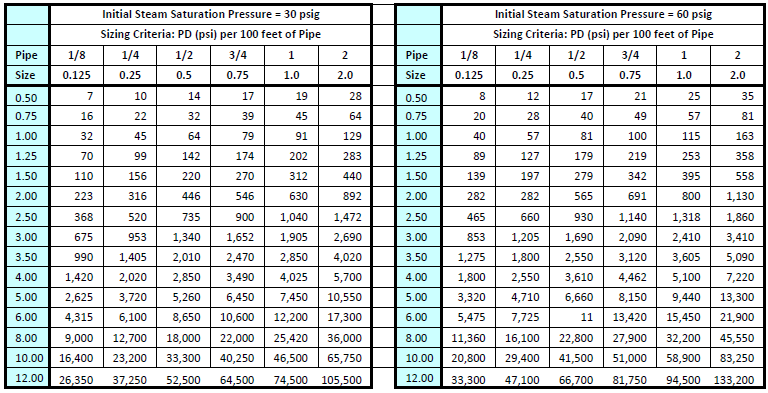

HIGH PRESSURE STEAMPIPE SIZING CRITERIA : Flow Rates of Steam (lbs/hr)

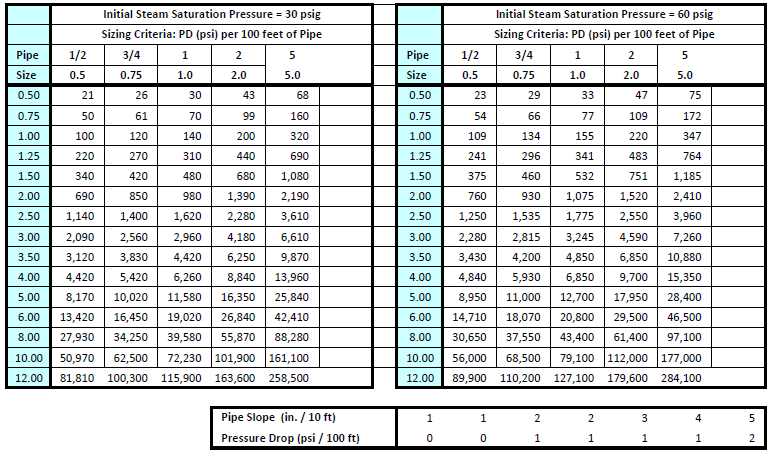

Pressure Drop (psi/100') sizing criteria for open gravity (sloped pipe) condensate return

CONDENSATE FLOWRATE (lbs/hr) Condensate Return Pressure = 0 psig

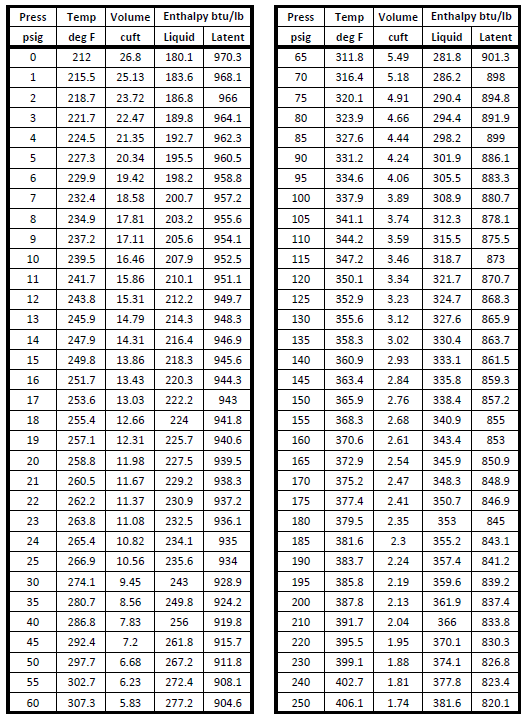

PROPERTIES OF STEAM

Example: 6800 lbs per hour of steam flow in a 2 1/2 inch pipe at 100 psig pressure.

What is the pressure (psi) drop per 100 ft length of pipe and the flow velocity?

Answer: psi/100' = 11 velocity = 32,000 fpm

Figure - 17 Steam Flow Rates at Various Pressures and Velocities for Schedule 40 Pipe Source: ASHRAE

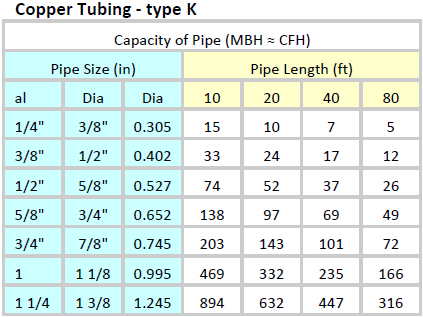

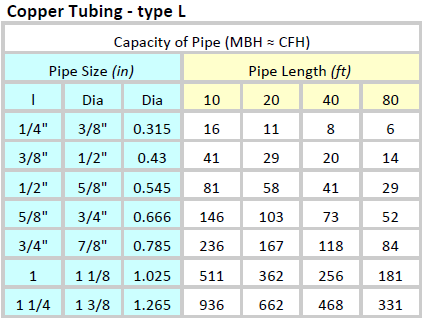

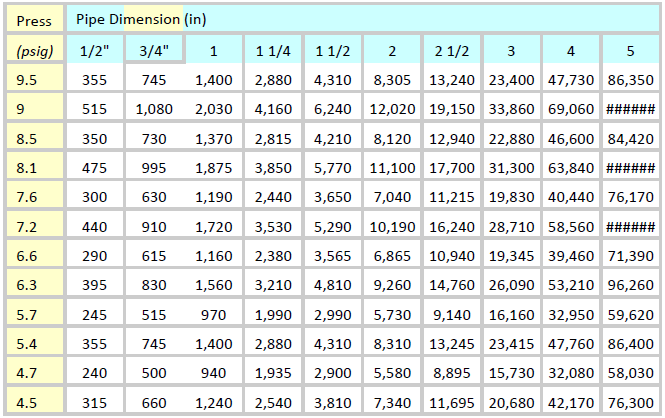

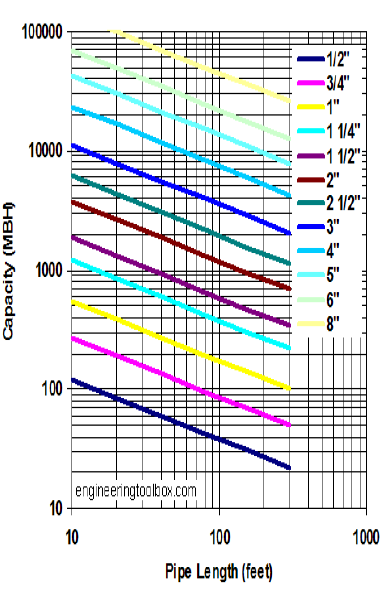

Natural Gas Pipe Sizing Tables and Charts

Steel Pipe - Schedule 40

Downstream Pressure

- inlet upstream pressure is more than 5 psig (35 kPa)

- fittings factor 1.2 - equivalent pipe length = pipe length + 20%

For natural gas the nominal BTU/cf varies from about 900 to 1100 BTU/cf. In general it is common to set

- 1 Cubic Foot (CF) = Approx 1,000 BTUs

- 1 CFH ≈ 1 MBH

- 1 Btu/h = 0.293 W

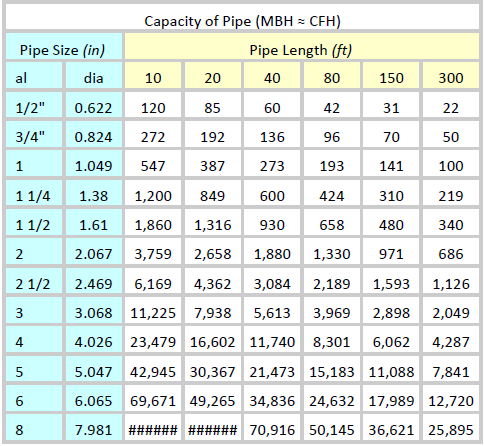

Steel Pipe - Schedule 40

- pressure less than 1 1/2 psig pressure drop 0.5 inches water column

- specific gravity of natural gas energy content in natural gas 10

- 1 Cubic Foot (CF) = Approx 1,000 BTUs 1 CFH = 1 MBH

- common to use fittings factor 1.5 - equivalent pipe length

in table above = pipe length + 50%

For natural gas the nominal BTU/cf varies from about

900 to 1100 BTU/cf. In general it is common to set

The capacity of a low pressure natural gas (less than 1 psi) pipe line can be calculated with the Spitzglass formula like

q = 3550 k ( h / l SG)1/2 (1)

where

| q = natural gas flow capacity (cfh) | h = pressure drop (inWater Column) |

| l = length of pipe (ft) | k = [d5 /(1 + 3.6/d + 0.03 d)]1/2 |

| d = inside diameter pipe (in) | SG = specific gravity |

For natural gas the nominal BTU/cf varies from about 900 to 1100 BTU/cf . In general it is common to set

1 Cubic Foot (CF) = approx 1,000 BTUs

1 CFH = 1 MBH

The specific gravity of natural gas varies from 0.55 to 1.0 .

The downstream pressure in a houseline after the meter/regulator is in general in the

range of 7 to 11 inches Water Column, or about 1/4 psi.

Example - Natural Gas Pipe Capacity

The capacity of a 100 ft natural gas pipe with a nominal diameter 0.5 inches (actual ID 0.622 in )

and 0.5 inches WC pressure drop can be calculated as

k = [(0.622 in )5 /(1 + 3.6 / (0.622 in) + 0.03 (0.622 in))]0.117

q = 3550 0.117 ( (0.5 in) / (100 ft) 0.60 ) 1/2 = 37.9 cfh

Specific gravity of natural gas is set to 0.60.

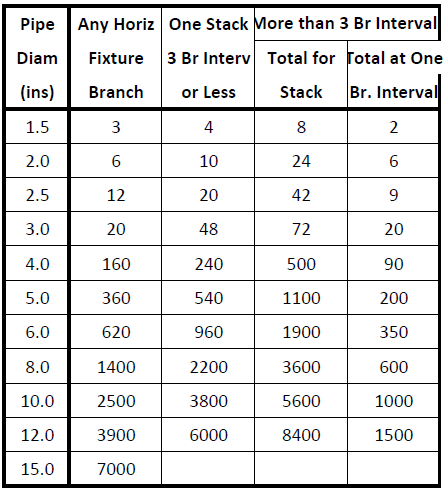

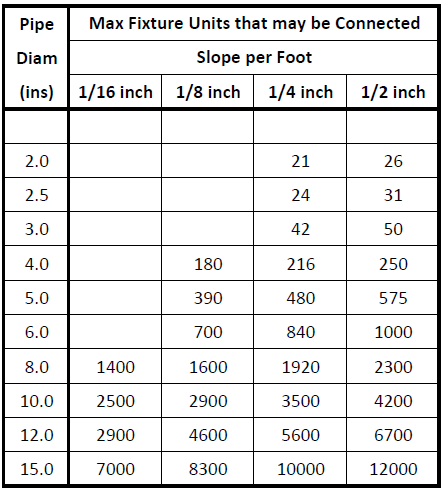

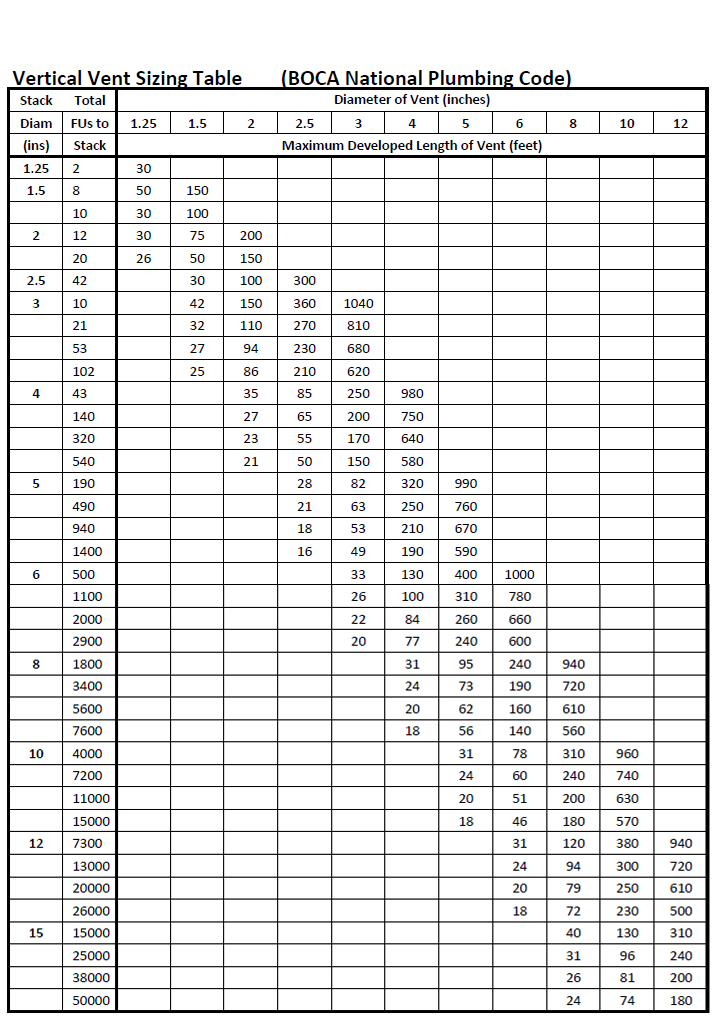

Horizontal Fixture Branches and Stacks | Building Drains and Sewers |

|

|

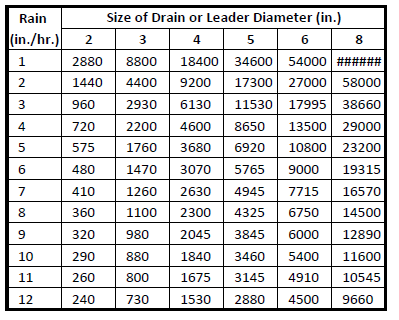

ROOF DRAIN AND LEADER SIZING

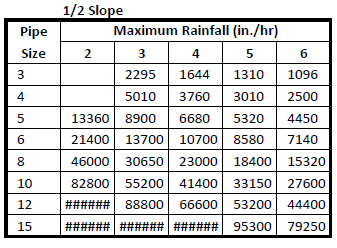

HORIZONTAL RAINWATER PIPE SIZING | HORIZONTAL RAINWATER PIPE SIZING |

|

HORIZONTAL RAINWATER PIPE SIZING

Example of Primary-Secondary Piping Network System