Basic Photovoltaic Principles and Methods

Notice

This publication was prepared under a contract to the United States Government. Neither the United States nor the United States Department of Energy, nor any of their employees, nor any of their contractors, subcontractors, or their employees, makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness or usefulness of any information, apparatus, product or process disclosed, or represents that its use would not infringe privately owned rights.

Printed in the United States of America

Available in print from:

Superintendent of Documents

U.S. Government Printing Office

Washington, DC 20402

Available in microfiche from:

National Technical Information Service

U.S. Department of Commerce

5285 Port Royal Road

Springfield, VA 22161

Stock Number: SERIISP-290-1448

Information in this publication is current as of September 1981

This book presents a nonmathematical explanation of the theory and design of PV solar cells and systems. It is written to address several audiences: engineers and scientists who desire an introduction to the field of photovoltaics, students interested in PV science and technology, and end users who require a greater understanding of theory to supplement their applications.

The book is effectively sectioned into two main blocks: Chapters 2-5 cover the basic elements of photovoltaics-the individual electricity-producing cell. The reader is told why PV cells work, and how they are made. There is also a chapter on advanced types of silicon cells. Chapters 6-8 cover the designs of systems constructed from individual cells-including possible constructions for putting cells together and the equipment needed for a practioal producer of electrical energy. In addition, Chapter 9 deals with PV's future. Chapter 1 is a general introduction to the field.

The authors of this document are Paul Hersch and Kenneth Zweibel. They would like to thank their colleagues at the Solar Energy Research Institute's Solar Electric Conversion Division who reviewed the manuscript for technical accuracy: Richard Bird, Kathryn Chewey, Satyen Deb, Keith Emery, Kay Firor, Steve Hogan, Larry Kazmerski, Jack Stone, Thomas Surek, and Simon Tsuo. Gary Cook and Richard Piekarski of the Technical Information Office, who designed the document, were also helpful readers. Graphic Directions of Boulder, Colorado, was responsible for the text's figures, often with valuable improvements. Ray David was the cover artist. Vincent Rice of the Photovoltaics Program Office at DOE was supportive throughout, giving impetus to the project.

Chapter 1

Introduction

Photovoltaic systems behave in an extraordinary and useful way: They react to light by transforming part of it into electricity. Moreover this conversion is novel and unique, since photovoltaics:

| • | Have no moving parts (in the classical mechanical sense) to wear out |

| • | Contain no fluids or gases (except in hybrid systems) that can leak out, as do some solar-thermal systems |

| • | Consume no fuel to operate |

| • | Have a rapid response, achieving full output instantly |

| • | Can operate at moderate temperatures |

| • | Produce no pollution while producing electricity (although waste products from their manufacture, and toxic gases in the event of catastrophic failure and disposal may be a concern) |

| • | Require little maintenance if properly manufactured and installed |

| • | Can be made from silicon, the second most abundant element in the earth's crust |

| • | Are modular permitting a wide range of solar-electric applications such as

|

| • | Have a relatively high conversion efficiency giving the highest overall conversion efficiency from sunlight to electricity yet measured |

| • | Have wide power-handling capabilities, from microwatts to megawatts |

| • | Have a high power-to-weight ratio making them suitable for roof application |

| • | Are amenable to on-site installation, i.e., decentralized or dispersed power |

Clearly, photovoltaics have an appealing range of characteristics.

However, there are ambivalent views about solar, or photovoltaic, cells' ability to supply a significant amount of energy relative to global needs.

| • | Those pro, contend: Solar energy is abundant, inexhaustible, clean, and cheap. |

| • | Those can, claim: Solar energy is tenuous, undependable, and expensive beyond practicality. |

There is some truth to both of these views. The sun's energy, for all practical purposes, is certainly inexhaustible. However, even though sunlight striking the earth is abundant, it comes in rather a dilute form.

THE SUN

The sun is an average star. It has been burning for more than 4-billion years, and it will burn at least that long into the future before erupting into a giant red star, engulfing the earth in the process.

Some stars are enormous sources of X-rays; others mostly generate radio signals. The sun, while producing these and other energies, releases 95% of its output energy as light, some of which cannot be seen by the human eye. The peak of its radiation is in the green portion of the visible spectrum. Most plants and the human eye function best in green light since they have adapted to the nature of the sunlight reaching them.

The sun is responsible for nearly all of the energy available on earth. The exceptions are attributable to moontides, radioactive material, and the earth's residual internal heat. Everything else is a converted form of the sun's energy: Hydropower is made possible by evaporation-transpiration due to solar radiant heat; the winds are caused by the sun's uneven heating of the earth's atmosphere; fossil fuels are remnants of organic life previously nourished by the sun; and photovoltaic electricity is produced directly from sunlight by converting the energy in sunlight into free charged particles within certain kinds of materials.

The Nature of Light Energy

Light is energy. You need only touch a black surface exposed to the sun to realize this fact. An understanding of the nature of light will help in comprehending how solar cells work.

The sun's light looks white because it is made up of many different colors that, combined, produce a white light. Each of the visible and invisible radiations of the sun's spectrum has a different energy. Within the visible part of the spectrum (red to violet), red is at the low-energy end and violet is at the high-energy endhaving half again more energy as red light. Light in the infrared region (which we can't see but feel as heat) has less energy than that in the visible region. Light in the ultraviolet region(which is invisible but causes the skin to tan) has more than that in the the visible region.

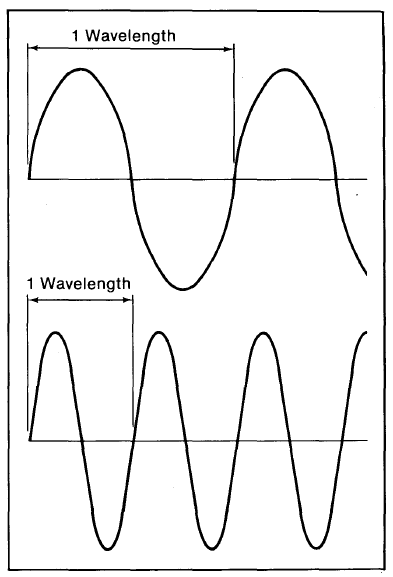

Visible light represents only a tiny portion of a vast radiation spectrum. Studies of light and similar radiation show that the way in which one light ray interacts with another or other physical objects often can be explained as if light were moving as a wave. For this reason it is useful to characterize light radiation by parameters associated with waves. All waves have a certain distance between peaks (called the wavelength) (Figure 1-1). This wavelength can also be expressed as a frequency (the number of peaks in a specified distance or during a specified time of propagation). Thus a wave with a long distance between peaks (long wavelength) has a lower frequency than one with a shorter wavelength (many peaks). (Note that frequency and wavelength vary inversely.) For light waves, the energy associated with the wave increases as the frequency increases (wavelength decreases). Red light has a wavelength of about 0.66 micrometers* (453 terahertz, or about 3 x 10 - 12 ergs [3 x 10 - 24 kW-h per "particle" of light [photon]), violet light, about 0.44 (682 terahertz, or about 4.5 x 10 -12 ergs [4.5 x 10 - 24 kW-h] per photon). X-rays are even shorter and more energetic. Microwaves (of the order of centimeters in wavelength) are longer than light waves and carry less energy.

Figure 1-1. Light interacts with itself and objects in a way that suggests it is a wave. Two ideal waves are depicted in the illustration. The top wave has a wavelength (the distance between two points where its shape repeats) that is twice that for the bottom one.

Every wave also has a frequency of propagation that is inversely related to the wavelength in a manner depending on the velocity of propagation of the wave: specifically, wavelength equals velocity of propagation divided by frequency. In the illustration the bottom wave has half the wavelength but twice the frequency of the one above it.

Sunlight Reaching Earth

Even though the sun ranks as a run-of-the-mill star, it releases a huge quantity of energy in terms of human capacity or need. Power output per second is 3.86 × 1020 megawatts (MW), several billion times the electric capacity of U.S. utilities. This energy fills the solar system, bathing the earth's atmosphere with a near constant supply of 1.37 kilowatts per square meter (kW/m2) .

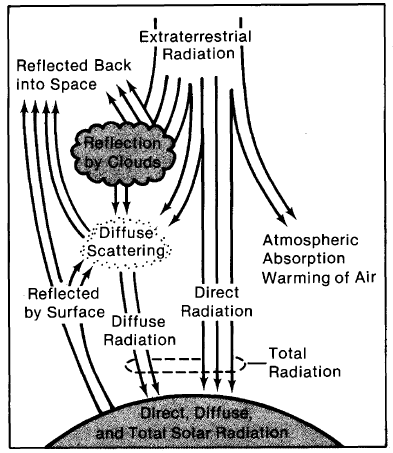

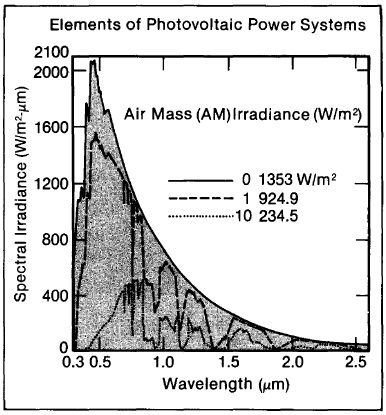

Not all of the direct sunlight incident on earth's atmosphere arrives at the earth's surface (Figure 1-2). The atmosphere attenuates many parts of the spectrum (Figure 1-3). For example, X-rays are almost totally absorbed before reaching the ground. A good percentage of ultraviolet radiation is also filtered out by the atmosphere. Some radiation is reflected back into space. Some is randomly scattered by the atmosphere, which makes the sky look blue.

It is valuable to relate the amount of sunlight at the earth's surface to the quantity, or air mass (AM), of atmosphere through which the light must pass. Radiation arriving at the surface of the earth is measured against that reaching the fringes of the atmosphere, where there is no air, and the air mass is zero (AMO). The light of the high-noon sun (and under further specified conditions) passes through an air mass of one (AM1). The intensity of the sunlight reaching the ground weakens for sun angles approaching the horizon since the rays have more atmosphere, or air mass, to penetrate. The atmosphere is a powerful absorber and can cut the sun's energy reaching the earth by 50% and more.

The peak intensity of sunlight at the surface of the earth is about 1 kW/m2. However, not all areas of the earth get the same average amounts of sunshine throughout the year. The most intensely bathed areas lie between 30o north and 30o south latitude, since these areas have the least cloud cover. There also are, of course, seasonal radiation variations caused by the tilt of the earth with respect to the sun. Thus, the winter sun will daily provide less than 20% of the summer sun's energy at some locations because it is lower in the sky and the days are shorter.

*A micrometer (J.lm) is one millionth of a meter.

Figure 1-2. The earth's atmosphere and clouds affect the way in which the sun's light reaches the surface of the earth.

All of these factors affecting the amount of local radiation on earth have to be taken into account when designing photovoltaic systems. The sun may be a constant source of energy, but at the earth's surface, the distribution of its energy and the constancy of its radiation are hardly ideal. A good PV system cannot be designed without providing for the variations associated with the energy spectrum and its local availability.

PHOTOVOLTAICS-A HISTORY

The physical phenomenon responsible for converting light to electricity-the photovoltaic effect-was first observed in 1839 by a French physicist, Edmund Becquerel. Becquerel noted a voltage appeared when one of two identical electrodes in a weak conducting solution was illuminated. The PV effect was first studied in solids, such as selenium, in the 1870s. In the 1880s, selenium photovoltaic cells were built that exhibited 1%-2% efficiency in converting light to electricity. Selenium converts light in the visible part of the sun's spectrum; for this reason, it was quickly adopted by the then-emerging field of photography for photometric (light-measuring) devices. Even today, light-sensitive cells on cameras for adjusting shutter speed to match illumination are made of selenium.

Figure 1-3. Light from the sun at the outer fringes of the earth's atmosphere (AMO) covers a broad range of wavelengths (frequencies). As the light comes through the earth's atmosphere it is selectively absorbed by certain elements in the atmosphere, resulting in chinks in the spectral distributions AM1 and AM10. Irradiance diminishes as the atmospheric mass (AM) numbers increase, since less light can penetrate the "thicker" atmospheres associated with the sun's not being directly overhead on a sparkling clear day (AM1). (Note that the frequency scale runs opposite to the wavelength scale.)

Selenium cells have never become practical as energy converters because their cost is too high relative to the tiny amount of power they produce (at 1% efficiency). Meanwhile, work on the physics of PV phenomena has expanded. In the 1920s and 1930s, quantum mechanics laid the theoretical foundation for our present understanding of PV. A major step forward in solar-cell technology came in the 1940s and early 1950s when a method (called the Czochralski method) was developed for producing highly pure crystalline silicon. In 1954, work at Bell Telephone Laboratories resulted in a silicon photovoltaic cell with a 4% efficiency. Bell Labs soon bettered this to a 6% and then 11% efficiency, heralding an entirely new era of power-producing cells.

Figure 1-4. In the future every home may supply at least part of its electric needs using root-mounted photovoltaics.

A few schemes were tried in the 1950s to use silicon PV cells commercially. Most were for cells in regions geographically isolated from electric utility lines. But an unexpected boom in PV technology came from a different quarter. In 1958, the U.S. Vanguard space satellite used a small (less than one-watt) array of cells to power its radio. The cells worked so well that space scientists soon realized the PV could be an effective power source for many space missions. Technology development of the solar cell has been a part of the space program ever since.

Besides the space program, another source, the transistor industry, contributed greatly to solar-cell technology. Transistors and PV cells are made from similar materials, and their workings ate determined by many of the same physical mechanisms. An enormous amount of research and development has been expended in improving the ever-useful transistor, and there has been a constant spin-off of valuable information in relation to solar cells. The situation has reversed recently: Much of the research being done in PV is affecting transistor technology.

Today, photovoltaic systems are capable of transforming one kilowatt of solar energy falling on one square meter into about a hundred watts' of electricity. Onehundred watts can power most household appliances: a television, a stereo, an electric typewriter, or a lamp. In fact, standard solar cells covering the sun-facing roof space of a typical home can provide about 8500-kilowatthours of electricity annually, which is about the average household's yearly electric consumption. By comparison, a modern, 200-ton electric-arc steel furnace, demanding 50,000 kilowatts of electricity, would require about a square kilometer of land for a PV power supply.

Certain factors make capturing solar energy difficult. Besides the sun's low illuminating power per square meter, sunlight is intermittent, affected by time of day, climate, pollution, and season. Power sources based on photovoltaics require either back-up from other sources or storage for times when the sun is obscured.

In addition, the cost of a photovoltaic system is far from negligible (electricity from PV systems in 1980 cost about 20 times* that from conventional fossilfuel- powered systems).

Thus, solar energy for photovoltaic conversion into electricity is abundant, inexhaustible, and clean; yet, it also requires special techniques to gather enough of it effectively.

*This is a very subjective figure because economic factors such as interest rates, taxes, tax deductions, competitive costs, and inflation are inherently variable; twentyfold is meant only as an estimate.

BIBLIOGRAPHY

Bailey, Robert L. 1980. Solar Electrics Research and Development. Ann Arbor, MI: Ann Arbor Sciences; pp. 2-186.

Cheremisinoff, Paul N.; Dickinson, William C. (eds.). 1980. Solar Energy Technology Handbook, Part A. New York, NY: Marcel Dekker, Inc.; pp. 1-167.

Dixon, A.E.; Leslie, J.D. (eds.). 1979. Solar Energy Conversion. New York, NY: Pergamon Press; pp. 1-37.

Rauschenbach, H.S. 1980. Solar Cell Array Design Handbook. New York, NY: Van Nostrand Reinhold Co.; pp. 6-14, 155-160.

Chapter 2

The Photovoltaic (PV) Effect

HIGHLIGHTS

The photovoltaic (PV) effect is the basis of the conversion of light to electricity in photovoltaic, or solar, cells. Described simply, the PV effect is as follows: Light, which is pure energy, enters a PV cell and imparts enough energy to some electrons (negatively charged atomic particles) to free them. A built-in-potential barrier in the cell acts on these electrons to produce a voltage (the so-called photovoltage), which can be used to drive a current through a circuit.

This description does not broach the complexity of the physical processes involved. Although it is impossible here to cover fully all the phenomena that contribute to a PV-generated current, it is possible to go deeply enough into these phenomena to understand how an effective cell works and how its performance can be optimized. We can do this by answering some fundamental questions about processes central to the working of a PV cell:

- What does it mean to say that an electron is freed?

- Where is it freed from?

- Where does it go?

- What is the potential barrier that acts on the free electrons?

- How is it formed?

- What does it do?

- Once acted on by the potential barrier, how do the free charges produce a current?

We shall take the silicon cell as a model. Silicon is a widely used, typical cell material; understanding the silicon cell is a good groundwork for understanding any PV cell. We shall start by reviewing some of silicon's basic atomic characteristics.

AN ATOMIC DESCRIPTION OF SILICON

All matter is made from atoms. They, in turn, are composed of three kinds of particles: protons, neutrons, and electrons. Protons (positively charged) and electrons (negatively charged) attract each other; neutrons are not electrically attracted to either and are said to be neutral. The positively charged protons and the neutral neutrons reside in a nucleus, the close-packed center of the atom. The electrons-much lighter than the protons (or neutrons)-orbit the nucleus. Although an atom contains charged particles, overall it is electrically neutral because it has the same number of protons and electrons.

Different atoms have different numbers of protons. For every proton in an atom's nucleus, there is an electron orbiting the nucleus. The orbital locations (and the motion of the electrons about their own axis) are determined by the energy of the electrons. The electrons, in particular those furthest from the nucleus, interact with electrons from other atoms and determine the way in which like or dissimilar atoms combine into larger structures such as solids.

The silicon atom has fourteen electrons arranged in such a way that the outer four can be given to, accepted from, or shared with another atom. These four outer electrons are called valence electrons.

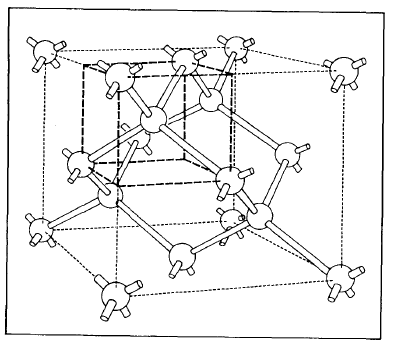

Large numbers of silicon atoms, through their valence electrons, can bond together to form a solid. As a solid, each silicon atom usually shares each of its four valence electrons with another silicon atom. Each basic silicon unit, forming a tetrahedral arrangement, thereby contains five atoms (the one silicon atom plus the four others it shares electrons with).

Each atom in the silicon solid is held in place at a fixed distance and angle with each of the atoms with which it shares a bond. This regular, fixed formation of a solid's atoms is called a crystal lattice.

Solids can form from several differently shaped crystal lattices. (All solids are not crystalline, however; some can have multiple crystalline forms and/or none at all.) For silicon (Figure 2-1) the atoms are located so as to form the vertices of a cube with single atoms centered at each of the faces of the cubic pattern. The cubic arrangement repeats throughout the crystal.

THE EFFECT OF LIGHT ON SILICON

When light strikes a silicon crystal, it may be reflected, be absorbed, or may go right through. Let's concentrate on the light that is absorbed. Usually when light of relatively low energy is absorbed by a solid, it creates heat without altering the electrical properties of the material. That is, low-energy light striking a silicon crystal causes atoms of silicon to vibrate and twist in their bound positions, but do not break loose. Similarly, electrons in bonds also gain more energy and are said to attain a higher energy level. Since these energy levels are not stable, the electrons soon return to their original lower energy levels, giving off as heat the energy they had gained.

Figure 2-1. Representation of the silicon crystal lattice arrangement.

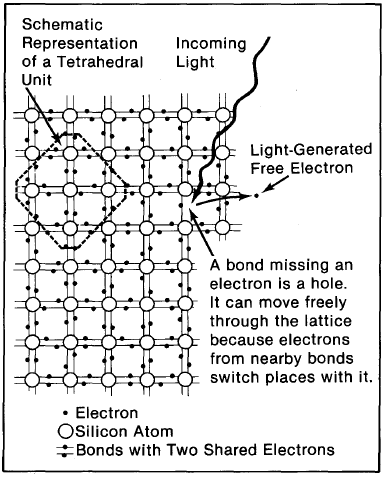

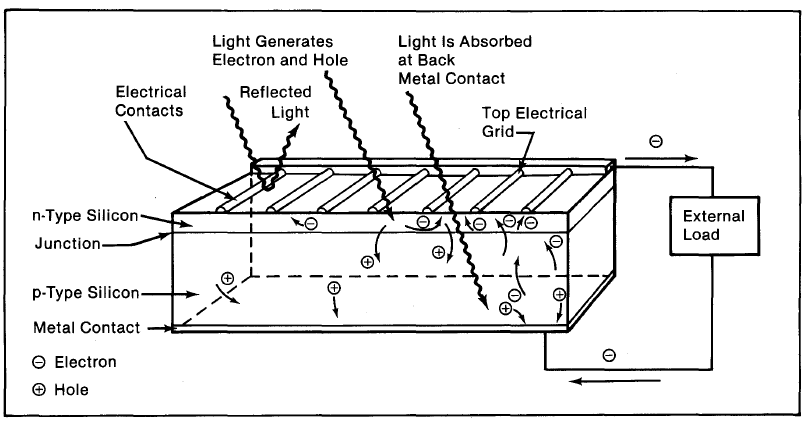

Light of greater energy can alter the electrical properties of the crystal. If such light strikes a bound electron, the electron is torn from its place in the crystal. This leaves behind a silicon bond missing an electron and frees an electron to move about in the crystal. A bond missing an electron, rather picturesquely, is called a hole. An electron free to move throughout the crystal is said to be in the crystal's conduction band (Figure 2-2), because free electrons are the means by which electricity flows. Both the conduction-band electrons and the holes play important parts in the electrical behavior of PV cells. Electrons and holes freed from their positions in the crystal in this manner are said to be light-generated electron-hole pairs.

A hole in a silicon crystal can, like a free electron, move about the crystal. The means by which the hole moves is as follows: An electron from a bond near a hole can easily jump into the hole, leaving behind an incomplete bond, i.e., a new hole. This happens fast and frequently-electrons from nearby bonds trade positions with holes, sending holes randomly and erratically throughout the solid. The higher the temperature of the material, the more agitated the electrons and holes and the more they move.

The generation of electrons and holes by light is the central process in the overall PV effect, but it does not itself produce a current. Were there no other mechanism involved in a solar cell, the light-generated electrons and holes would meander about the crystal randomly for a time and then lose their energy thermally as they returned to valence positions. To exploit the electrons and holes to produce an electric force and a current, another mechanism is needed-a built-in "potential" barrier. *

Figure 2-2. Light of sufficient energy can generate electron-hole pairs in silicon, both of which move for a time freely throughout the crystal.

8The barrier is called "potential" because it is an electrical phenomenon having to do with how much energy a particle (electron or hole) would "potentially" gain if that particle encountered the barrier and were accelerated.

THE POTENTIAL BARRIER

The Function of the Barrier

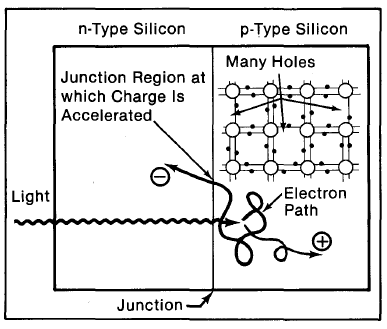

A PV cell contains a barrier that is set up by opposite electric charges facing one another on either side of a dividing line. This potential barrier selectively separates light-generated electrons and holes, sending more electrons to one side of the cell, and more holes to the other. Thus separated, the electrons and holes are less likely to rejoin each other and lose their electrical energy. This charge separation sets up a voltage difference between either end of the cell (Figure 2-3), which can be used to drive an electric current in an external circuit.

Figure 2-3. A potential barrier ina solar cell separates light-generated charge carriers, creating a voltage.

Forming the Barrier

There are several ways to form a potential barrier in a solar cell. One is to slightly alter the crystal so that its structure on either side of the dividing line is different.

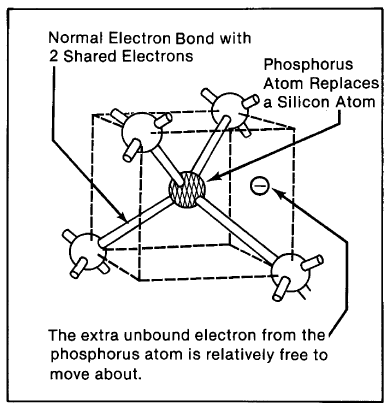

The Negative-Carrier (Donor) Dopant. As previously indicated, silicon has four valence electrons, all of which are normally part of bonds in a silicon crystal. Suppose by some means we introduce an impurity into an otherwise pure silicon crystal by substituting for a silicon atom an atom such as phosphorus, having five valence electrons. The impurity atom would occupy the same position in the crystal as a normal silicon atom, supplying an electron for each of silicon's four bonds. But because the phosphorus atom has one extra valence electron, there would be one electron with no bond to share (Figure 2-4). Compared with a bound electron, the impurity atom's extra electron is relatively free. In fact, at room temperature there is enough thermal energy in the crystal to shake this electron loose, despite the fact that it would leave behind a positively charged impurity atom.* This free electron from the impurity has no hole (empty bond) into which it may readily drop, and it behaves as if it were a permanent member of the crystal's conduction band, always ready to be part of an electric current.

*A charged atom is called an "ion."

A silicon crystal with numerous substituted phosphorus atoms would have many free, conductionband electrons and a similar number of positive impurity ions locked into the crystal's structure. Overall, the whole crystal would remain neutral, since there are just as many positive ions as free electrons; but the crystal's electrical properties would have been drastically altered.

Figure 2-4. When an impurity atom such as phosphorus with five valence electrons is substituted into a silicon crystal, it has an extra, unbonded electron.

Impurities introduced in this way are called dopants, and dopants that have one extra valence electron (such as phosphorus introduced into a. silicon crystal) are called donors because they donate an electron to the crystal. Such a donor-doped crystal is known as n-type because it has free negative charges.

Altering silicon by introducing a donor dopant is part of the process used to produce the internal potential barrier. But n-type silicon cannot of itself form the barrier; other, slightly altered silicon is also necessary, this kind with electrical properties opposite those of the n-type silicon.*

*There are other ways of forming the barrier such as contacting the silicon with metal or with charged silicon dioxide; these are described in later chapters.

The Positive-Carrier (Acceptor) Dopant. An appropriately altered material can be formed by substituting into the silicon crystal, impurity atoms with one fewer valence electron than silicon. An impurity atom with three valence electrons (such as boron) would sit in the position of the original silicon atom, but one of its bonds with the silicon would be missing an electron, i.e., there would be a hole (Figure 2-5). As we saw before, holes can move about almost as freely as conduction-band electrons. In this way, a silicon crystal doped with many such boron atoms has many holes that act as if they were free positive charges moving throughout the crystal lattice.

Figure 2-5. A three-valence-electron impurity (such as boron) in a silicon crystal is normally bonded, except one of the bonds is missing an electron, i.e., is a hole.

A three-valence-electron impurity in a silicon crystal is called an acceptor because its holes accept electrons (normally bonded valence electrons or conductionband electrons) from the rest of the silicon crystal. An acceptor-doped silicon material is called p-type because of the presence of free positive charges (the moving holes).

In a p-type material, positive charges are the so-called majority (charge) carriers because they far outnumber any free electrons that in p-type materials are referred to as minority carriers. In an n-type material, where the doping is reversed, electrons (negative charges) are the majority carriers and holes the minority carriers.

The Junction. A line dividing n-type from p-type silicon establishes the position of a potential barrier essential to the operation of a solar cell. To see how this barrier comes into being, let's take a look at the junction between the two materials (the area in the immediate proximity of the two surfaces). In the p-type material, there are excess holes; in the n-type material, excess electrons (Figure 2-6a). When the nand p materials are in contact, free electrons in the n-type material adjacent to the many holes in the p-type material at the junction will jump into the p-type material, filling the holes. Also, valence band electrons on the n-type side can jump into holes on the adjacent p-type side, which is equivalent to a hole moving over into the n-type material (for simplicity, this is not shown in Figure 2-6). This charge transference process happens rapidly along the dividing line (junction), sending huge numbers of electrons to 'the p-type side and holes to the n-type side (Figure 2-6b). This causes an immediate imbalance of charge: more negative charges (extra electrons) along the p-type side of the interface, more positive charges (ions) along the n-type side (Figure 2-6c).

When electrons move over into the p-type material during junction formation, they find holes in the silicon bonds and drop into them. In like manner, holes that transfer to the n-type side are quickly filled by the n-type side's numerous extra electrons. Consequently, carriers that form the junction lose their freedom of movement. Thus, although a charge imbalance exists at the junction, there are very few free electrons on the p-type silicon side to be pulled back to the n-type side, and very few free holes on the n-type side to be transferred back to the p-type material. So, the charge imbalance stays fixed in place.

The Barrier. The process of charges moving across the junction to create a charge imbalance in the abovedescribed manner does not continue indefinitely. Charged carriers that have already crossed the junction set up an electric force (field) that acts as a barrier opposing the further flow of free carriers. As more carriers cross the junction, the barrier enlarges, making it increasingly difficult for other carriers to cross. Eventually, an equilibrium is established where (statistically speaking) no more electrons or holes switch sides. This creates a fixed potential barrier at the junction (the barrier to which we have been referring since the beginning), with the n-type side adjacent to the junction being positively charged and the p-type side adjacent to the junction being negatively charged. The "height" (that is, the strength of the electric force) of the barrier, it should be noted, depends upon the amount of dopant in the silicon-the more the dopant, the more charge imbalance induced and the greater the barrier's ability to separate charges.

Let us note some qualities of the barrier (Figure 2-6d). It opposes the crossing of majority charge carriers. That is, electrons in the n-type material would have to climb the barrier against the built-in field to enter the p-type material. Similarly, holes in the p-type region are held back from entering the n-type region. Note also that minority carriers are not hindered by the barrier. In fact, free electrons on the p-type side- of which there are very few, being the minority carrier there-are driven by the junction field to the opposite, n-type side. The same is true of holes driven from the n-type side. But normally (under no illumination) there are so few minority carriers on their respective sides that their movement is nil; and what there is, is balanced by the few majority carriers that randomly assume enough energy to cross the barrier. This selective barrier at the junction is the means of separating charges during electron-hole generation under illumination. It is the key to the production of a PV electric current.

Figure 2-6. During junction formation, electrons move from the n-type silicon into the p-type, while holes move in the opposite direction. Movement of electrons into the p-type silicon and holes into the n-type silicon builds up a fixed potential barrier at the junction opposing the further movement of free carriers and creating a state of equilibrium.

The Potential Barrier in Action

For illustrative purposes, suppose light striking the PV cell has enough energy to free an electron from a bond in the silicon crystal. This creates an electronhole pair-a free electron and a free hole. Suppose further that the electron-hole pair is generated on the p-type silicon side of the junction. An electron from such an electron-hole pair has only a relatively short time during which it is free because it is very likely to combine with one of the numerous holes on the p-type side. But solar cells are designed so that in all probability the electron will meander around the crystal and encounter the junction before it has the chance to combine with a hole (Figure 2-7). (Were it to combine with a hole, it would lose its energy as heat and be useless as far as PV electric current is concerned.)

Once the free electron is within the field of the junetion(which is limited to the junction's immediate vicinity), the electron is accelerated across the barrier (by the barrier's charge imbalance) into the n-type silicon. Since there are very few holes on the n-type side of the junction, the electron is no longer in great danger of recombining. Moreover, there is very little chance of its returning to the p-type side because it would have to buck the repulsion of the junction's field (climb the barrier), expending energy it usually doesn't have.

The hole partner of this electron-hole pair, however, remains on the p-type side of the junction because it is repelled by the barrier at the junction. It is not in danger of recombining because there are already a predominance of holes on the p-type side.

Figure 2-7. A photogenerated electron on the p-type side usually has enough time to bounce randomly around the crystal and encounter the junction before it can combine with a hole.

A similar situation occurs when the electron-hole pairs are generated by light on the n-type side of the junction. This time the freed electrons remain on the n-type side, being repelled by the barrier. Meanwhile, most of the holes encounter the junction before chancing to recombine. They cross the junction into the p-type side when normally bound electrons from the p-type side jump the junction and fill the holes. Once on the p-type side, the holes move around unhindered, and there are very few free electrons available to fill them.

Because illumination and charge separation causes the presence of uncombined excess negative charges on the n-type side and excess holes on the p-type side, a charge imbalance exists in the cell.

Figure 2-8. Light incident on the cell creates electron-hole pairs, which are separated by the potential barrier, creating a voltage that drives a current through an external circuit.

THE ELECTRIC CURRENT

If we connect the n-type side to the p-type side of the cell by means of an external electric circuit, current flows through the circuit (which responds just as if powered by a battery} because this reduces the lightinduced charge imbalance in the cell. Negative charges flow out of the electrode on the n-type side, through a load (such as a light bulb}, and perform useful work on that load (such as heating the light bulb's filament to incandescence}. The electrons then flow into the p-type side, where they recombine with holes near the electrode (Figure 2-8). The light energy originally absorbed by the electrons is used up while the electrons power the external circuit. Thus, an equilibrium is maintained: The incident light continually creates more electron-hole pairs and, thereby, more charge imbalance; the charge imbalance is relieved by the current, which gives up energy in performing work.

The amount of light incident on the cell creates a nearproportional amount of current. The amount of energy it takes to raise an electron to the conduction band is the amount of energy the light originally imparts to the electron and is, thus, the maximum that can be retrieved from the electron in the external circuit.

We have observed all the conditions necessary for current to flow: incident light to free the charge carriers, a barrier to accelerate the carriers across the junction and keep them at opposite ends of the cell, and a charge imbalance to drive a current (charged carriers) through a circuit.

BIBLIOGRAPHY

Backus, Charles E. (ed.}. 1976. Solar Cells. New York, NY: IEEE Press.

Chalmers, Bruce. 1976. "The Photovoltaic Generation of Electricity." Scientific American. Vol. 235 (No.4): pp.34-43.

Johnston, W.D., Jr. 1980. Solar Voltaic Cells. New York, NY: Marcel Dekker, Inc.; pp. 19-51.

Meinel, Aden B.; Meine], Marjori P. 1976. Applied Solar Energy. Reading, MA: Addison-Wesley Publishing Co.; pp. 526-544.

Noll, Edward M. 1975. Wind/Solar Energy. Indianapolis, IN: Howard W. Sams and Co., Inc.; pp. 7-44.

Pulfrey, David L. 1978. Photovoltaic Power Generation. New York, NY: Van Nostrand Reinhold Co.; pp. 66-113.

Tauc, Jan. 1972. Photo and Thermoelectric Effects in Semiconductors. New York, NY: Pergamon Press; pp.90-129.

Chapter 3

Physical Aspects of

Solar Cell Efficiency

HIGHLIGHTS

Most of the energy that reaches a cell in the form of sunlight is lost before it can be converted into electricity. Maximal sunlight-to-electricity conversion efficiencies for solar cells range up to 30% (and even higher for some highly complex cell designs), but typical efficiencies are 10%-15%. Most current work on cells is directed at enhancing efficiency while lowering cost. Certain physical processes limit cell efficiency-some are inherent and cannot be changed; many can be improved by proper design.

The major phenomena that limit cell efficiency are:

- Reflection from the cell's surface

- Light that is not energetic enough to separate electrons from their atomic bonds

- Light that has extra energy beyond that needed to separate electrons from bonds

- Light-generated electrons and holes (empty bonds) that randomly encounter each other and recombine before they can contribute to cell performance

- Light-generated electrons and holes that are brought together by surface and material defects in the cell

- Resistance to current flow

- Self-shading resulting from top-surface electric contacts

- Performance degradation at nonoptimal (high or low) operating temperatures

REFLECTION

Some of the sunlight that strikes a solar cell is reflected. Normal, untreated silicon reflects 36% (or more) of the sunlight that strikes it. This would be a horrendous loss in terms of efficiency. Fortunately, there are several ways of treating cell surfaces to cut reflection drastically. Among them are chemically coating and texturing the surface (these are covered in some detail in the next chapter). By dint of these methods, reflection can be lowered to a quite manageable 5% or so.

LIGHT WITH TOO LITTLE OR TOO MUCH ENERGY

Effects (2) and (3) are closely related: Efficiency losses are associated with light that either is not energetic enough (2) or too energetic (3) for the proper generation of an electron-hole pair. As stated in Chapter 1, sunlight has a varied spectrum; light reaching the earth has widely differing intensities at a broad spectrum of wavelengths. Losses associated with effects (2) and (3) result from how the light of varying wavelengths interacts with the solar cells.

Light entering a solar cell can (Figure 3-1)-

- Go right through it

- Become absorbed, generating heat in the form of atomic vibrations

- Separate an electron from its atomic bond, producing an electron-hole pair

- Produce an electron-hole pair but have an excess of energy, which then becomes heat

Only (c) is a near-perfect means of transforming sunlight into electricity.

At an energy that is specific to the material and its atomic structure, light can free an electron from its atomic bond (c) rather than just cause that bond to vibrate. Different solar cell materials have a different characteristic energy at which electrons are freed (socalled electron-hole generation).

For silicon, the energy is 1.1 electron volts;* for gallium arsenide, another cell material, it is 1.4 electron volts; other usable cell materials have characteristic energies ranging from 1 to 2.6 electron volts. This characteristic energy is called the material's band gap energy (the gap between the valence and conduction bands).

*An electron-volt is a measure of very small energies appropriate to atomic sizes. One electron-volt is the kinetic energy (energy of movement) an electron gains when it is accelerated by one volt of electric potential. which is slightly less than the voltage from a common flashlight battery.

Since the sun's spectrum has a wide variety of energies and intensities, the key is to match a material and its characteristic band gap energy with the spectrum so that the maximum amount of energy in the sun's spectrum falls just above the characteristic energy. Figure 3-2 shows how efficiency varies with the energy needed to generate an electron-hole pair. Notice that the energy required to free electrons in gallium arsenide, at 1.4 electron volts, nearly coincides with the peak efficiency associated with the spectrum; silicon, at 1.1 electron volts, is just below the peak efficiency.

Figure 3-1. What happens to light entering a cell? It can go through (a), can be absorbed as heat (b), can generate an electron-hole pair (c), or can generate an electron-hole pair and have excess energy that is lost as heat (d).

These estimates of efficiency assume effect (d), where light with energy greater than that needed for electronhole generation frees an electron but has excess energy that also produces heat.

The production of electron-hole pairs is essential to the working of a solar cell. Without it, no voltage can be generated and no current can flow. Effects (a) and (b) mentioned above are a total loss; effects (c) and (d) produce free electrons and holes, although some of the incident light's energy becomes heat in (d). Overall, these inefficient interactions of light with the cell material waste about 55% of the energy from the original sunlight. They are the largest single reason conventional solar cells cannot produce electricity with an energy equivalent to that from the sunlight falling on the cell. For comparison, consider how much more efficient solar cells would be if the sun's spectrum consisted of just one wavelength (monochromatic) and that was matched exactly to the energy the cell required to generate electron-hole pairs!*

*Such near-100% conversion of incoming light is the research goal of several projects in which sunlight is processed by various devices to make it monochromatic-however, investigation of these devices is beyond the purpose of this text.

Figure 3-2. Maximum efficiency calculated as a function of the energy needed to free an electron, assuming the outer space solar spectrum (AMO) incident on the cell and assuming a terrestrial solar spectrum (AM1); several semiconductors of interest are indicated (Cheremisinoff and Dickinson, 1980, p. 500).

RECOMBINATION OF ELECTRON· HOLE PAIRS

Loss mechanisms (4) and (5) result from the inadvertent recombination of electrons and holes before they can contribute to an electric current. Typically, these are small losses, because cells have been carefully designed to eliminate them.

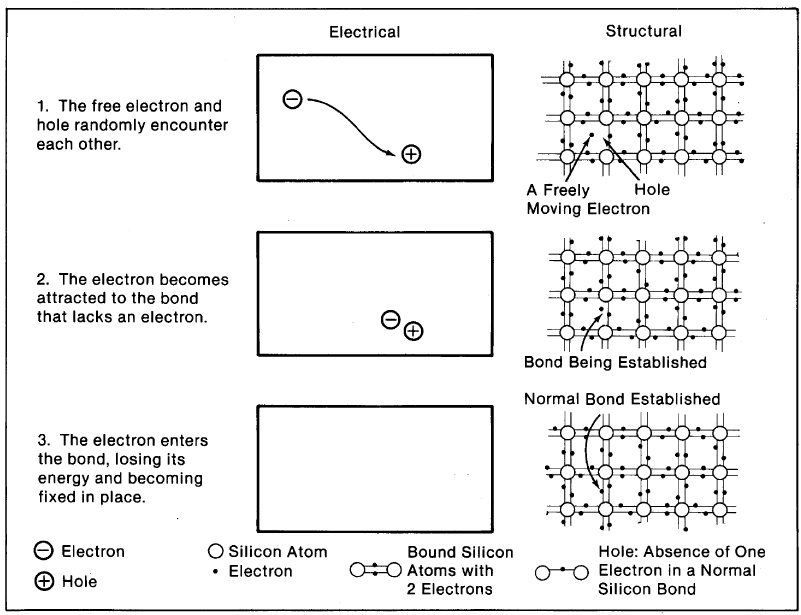

Recombination of electrons and holes occurs in two ways, which can be characterized as direct and indirect recombination.

Direct Recombination

Direct recombination is relatively rare. It happens when an electron and a hole randomly encounter each other, and the electron falls back into the hole. Thus the material's original bonds are reasserted (Figure 3-3), and the electron's and hole's energies are lost as heat.

Figure 3-3. Direct recombination of an electron and a hole occurs randomly when an electron is near an empty bond. When the electron falls into the bond, it loses the energy it picked up from the light that freed it. This energy becomes heat.

Direct recombination is a problem only before the light-generated charge carriers are separated by the PV cell's junction (see Chapter 2). Recall that on the n-type side of the junction there are a preponderance of free electrons; on the p-type side, a preponderance of mobile holes. When light generates an electron-hole pair on the n-type side, the hole is in immediate danger of being filled by one of the huge number of free electrons. Cells must be designed to minimize the time the holes spend on the n-type side before they can be moved to the p side by the junction field. But once a hole reaches the p-type side (where it can contribute to an effective voltage) it is in relatively little danger of encountering free electrons, which are rare on the p-type side. The same argument can be applied to electrons generated by light on the p-type side; they must quickly be shuttled over to the n-type side to avoid recombination.

Indirect Recombination

Indirect recombination can occur in many ways. ("Indirect" means that the electron and hole do not just run into each other and combine-the interaction is influenced by further circumstances.) Contrary to what one might expect, indirect recombination is much more of a problem in solar cells than direct recombination. Experiment has shown that electrons and holes are lost via recombination in about a hundredth of a second, on average. (This gives an idea of how fast charge carriers must be separated by the junction in actual cells.) Calculations show that the direct recombination of an electron and hole would take place in about 1 second-one hundred times slower than actual measured recombination rates (Tauc, 1962, p. 69). Thus indirect recombination is dominant, causing a hundredfold increase in the recombination rate. The actual mechanisms of indirect recombination are manifold.

In the bulk of the material, recombination may be caused by empty, or dangling, bonds from impurities or defects (fractures), which can capture free electrons or holes.

Another recombination mechanism occurs when a free charge carrier has a collision, reducing its energy and raising the likelihood that it will fall into a bond. This is related to the intrinsic resistance in the cell (see the next section): More resistance reduces charge mobility, causing more recombination and less current and voltage.

The surface of a solar cell can be the site of much recombination. Minute "bridges" crossing the junction can exist on the cell's surface, giving the charge carriers a path that effectively avoids the junction's field. Charge carriers then filter back across the junction (in the opposite direction to junction-directed flow), diminishing cell voltage and current. Surfaces are also notoriously prone to unconventional atomic structures with numerous sources of collision and with dangling bonds; as such, they are regions where electrons and holes have many opportunities to recombine.

RESISTANCE

Resistance to the flow of current (i.e., the flow of electrons and holes) occurs in any electric circuit. We are most familiar with it from Ohm's law, V = JR, which can be rewritten as:

R = V/I,

where V is voltage, I is current, and R is resistance. This law is only true for certain materials at certain temperatures and currents. (It is not true for solar cells because recombination losses are not proportional to resistance.) Resistance is ever-present in most electrical elements, where the flow of current is accompanied by collisions between charge carriers and the material the charges are flowing through. Electric resistance can be so great that it can be used to provide heat (stoves) or light (light bulbs). Thus, resistance losses in cells are equivalent to energy losses; whatever a solar cell loses because of resistance degrades its efficiency.

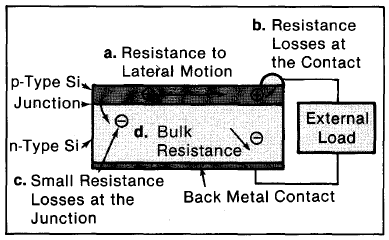

Resistance losses in solar cells occur predominantly in three places: in the bulk of the base material, in the narrow top-surface layer typical of many cells, and at the interface between the cell and the electric contacts leading to an external circuit (Figure 3-4). Resistance losses lower voltage and enhance the chances of recombination of charges, reducing current. Usually it is better to highly dope silicon to reduce resistance: Highly doped silicon has numerous free carriers to conduct the current. However, there are limitations associated with doping. Lattice damage can occur, and eventually there can be so many free carriers that the junction is defeated. (This is similar to the high temperature effect, see below.)

Figure 3-4. Most pn-junction cells have a very thin top layer. Just as resistance to water's flowing in a pipe is large for a narrow pipe, so is the resistance to lateral current flow large for electric charges in this thin top layer (a). Similarly, resistance losses are large at the electric contact (b), because of the poor interface between materials where disruptions in the atomic structure obstruct movement of charge carriers. There is even some (but very little) resistance loss at the junction (c) where the carriers, although accelerated, may lose some energy. The bulk of the material also has a resistance (d).

A representation of recombination and resistance losses can be seen in Figure 3-5.

Figure 3-5. The current and current losses of a solar cell can be modeled by a simple circuit with a current generator (J), a loss of current from recombination effects (Jr) resistance losses (R), and a shunt loss from current that returns across the junction (Rsh). Note that Jr reduces the current (arrows) reaching the external load, as does the path through Rsh (which would be optimized if it were infinite, i.e., no current could return across the junction). The resistance (R) blocks the flow of current, reducing voltage to load proportionately.

SELF-SHADING

Self-shading (7), like reflection (1), is one of the more obvious loss mechanisms in cells. It refers to losses engendered by the electrical grid on top of the cell, which reflects light that otherwise would enter the cell. Since resistance is maximal to lateral movement in the top-surface layer of the cell, there must be many charge removal points to minimize resistive effects. Thus electric contacts are not placed far from the charge carriers. The result is a grid-like geometrynarrow fingers of conductive material spread over the front surface of the cell. This electric grid shades a portion of the cell's top surface: A typical shading loss percentage is 8%, but some cells have losses as high as 20% and others as low as 3% (and less).

PERFORMANCE DEGRADATION AT NON-OPTIMAL TEMPERATURES

Solar cells work best at certain temperatures, according to their material properties: Some materials are more appropriate for use in orbit around the earth, some for terrestrial uses, and others for hightemperature applications either under concentrated sunlight or in space near the sun. Figure 3-6 shows how different cell materials lose efficiency with increasing temperature. Note that at normal terrestrial temperatures, 25oC, silicon's efficiency compares favorably with other materials; but at high temperatures, 200oC for instance, silicon's efficiency has dropped to 5%, whereas the other materials are near 12%. Silicon is a good material for ambient temperature terrestrial uses; it fails in high-temperature applications.

Although Figure 3-6 does not show it, there is a similar drop-off of efficiency below a certain low temperature for each of the materials.

Figure 3-6. Solar cells efficiency versus temperature for various materials: Note that all materials lose efficiency in the range shown.

High-Temperature Losses

The physical effects that determine efficiency's relationship with temperature are quite complex. For the most part, two predominate in causing efficiency to drop as temperature rises: As thermal energy increases, (1) lattice vibrations interfere with the free passage of charge carriers and (2) the junction begins to lose its power to separate charges. The first effect severely degrades silicon's performance even at room temperatures (Figure 3-7). The second effect does not occur until temperatures of about 300oC for silicon are reached. At such temperatures, a huge number of electrons in normal silicon bonds are thermally jostled from their positions; on the n-type side, they join and greatly outnumber the free electrons donated by the n-type dopant. At the same time holes are formed on the n-type side (left behind by the thermally freed electrons); the n-type silicon begins to lose its n-type character as the number of free electrons and holes become similar. The same process is working on the p-type side, which is losing its p-type character. This leads to two effects: (1) The thermally agitated charge carriers have so much energy, they cross over the junction in both directions almost as if the barrier field were not there. (2) Ultimately the junction itself disappears because there are no longer n- and p-type sides to induce it. All of these effects accumulate to erode the activity of the cell, and efficiency diminishes to nearly zero.

Figure 3-7. The ability of charge carriers to move without losing their energy is measured by their mobility, here shown for silicon (doped at two different donor concentrations) in relation to temperature. Note that silicon is already below its maximum efficiency at room temperature. The hightemperature losses shown here are mostly due to collisions with thermally excited atoms.

Since solar cells are sensitive to temperature increases, and since so much of the light energy incident on cells becomes heat (due to inefficiencies), it is frequently necessary to either match the cell material to the temperature of operation or to continually cool it, removing the extra, unwanted heat. Sometimes this latter method can lead to positive results, actually raising a solar installation's overall efficiency if the heat is applied to useful purposes (see Chapter 6).

Low-Temperature Losses

Low-temperature losses are, if anything, more complex and less understood. (They are important, however, only for deep-space PV applications.) Two effects are thought to play roles: (1)As temperature falls, thermal energy is less able to free charge carriers from either dopant atoms or intrinsic silicon. Mobility for light-generated charge carriers drops because they collide more frequently with ionized donors or acceptors in n- and p-type regions, respectively. The donors and acceptors are not screened as much by clouds of thermally aroused charge carriers. Also (2) at very low temperature, there is so little thermal energy that even dopants behave as if they were normal silicon atoms. For instance, in the n-type material, donor atoms retain their extra electrons; in the p-type material, holes remain fixed in place because electrons are less likely to pop out of their normal positions to fill them. Since the n- and p-type sides no longer exhibit their doped character, the junction disappears. (Recall that a junction forms only in response to imbalanced donor/acceptor concentrations.)

BIBLIOGRAPHY

Cheremisinoff,Paul N.; Dickinson, William C. (eds.). 1980. Solar Energy Technology Handbook, Part A. New York, NY: Marcel Dekker, Inc.; pp. 483-515.

Grove, A.S. 1967. Physics and Technology of Semiconductor Devices. New York, NY: John Wiley and Sons.

Meinel, Aden B.; Meinel, Marjorie P. 1976. Applied Solar Energy. Reading, MA: Addison-Wesley Publishing Co.; pp. 526-550.

Pulfrey, David L. 1978. Photovoltaic Power Generation New York, NY: Van Nostrand Reinhold Co.

Sutton, George W. 1966. Direct Energy Conversion. New York, NY: McGraw-Hill Book Co.; pp. 1-37.

Wolf, M. 1976. "Limitations and Possibilities for Improvement of Photovoltaic Solar Energy Converters." Solar Cells. Charles E. Backus (ed.). New York, NY: The Institute of Electrical and Electronics Engineers, Inc.; pp. 118-135.

Wolf, M. 1976. "A New Look at Silicon Solar Cell Performance." Solar Cells. Charles E. Backus (ed.). New York, NY: The Institute of Electrical and Electronics Engineers, Inc.; pp. 191-201.

Chapter 4

The Typical Single-Crystal

Silicon Solar Cell

HIGHLIGHTS

Single-crystal silicon is the most frequently used, bestunderstood material for solar cells. Knowledge of silicon's electrical properties and expertise with its manufacture have been gained in the transistor industry and in the solar cell industry, which has supplied arrays for generating power in space for over two decades.

Silicon does not exist in a single-crystal form in nature. Rather, it exists as silica, or silicon dioxide (SiO2), a compound of the two most abundant elements in the earth's surface. (Almost 60% of the earth's crust is silica.) A material called quartzite, which can be almost 99% silica in high-grade mineral deposits, is the usual starting point for producing silicon for solar cells. Other materials with a large amount of silicon-such as sand-are not good raw materials because they have too many impurities, which are costly to eliminate. Given the relative abundance and inexpensiveness of quartzite, it is clear that silicon is an attractive solar cell material.

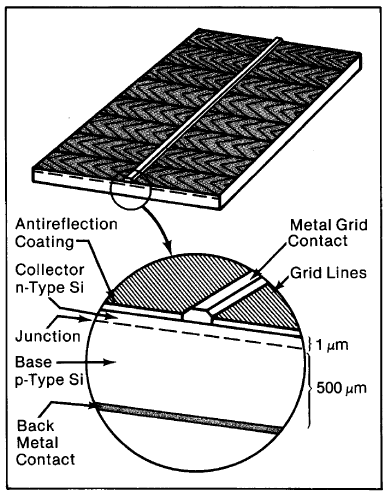

A typical pn-junction single-crystal silicon solar cell has several layers (Figure 4-1): a conducting grid on the top surface; an antireflective coating and/or treated surface layer; a thin layer of usually n-type silicon about one micrometer thick (called the collector); a very narrow junction-field region where there are almost no free charge carriers; a silicon base layer, oppositely doped to the collector (usually p-type); and a back-contact electrode. This chapter describes how each of these cell features is made and its practical functioning.

MAKING THE BASE LAYER

To make a solar cell, the starting raw material, quartzite, which is 90% or more silica (SiO2), must be refined and its impurities removed. The process begins when the quartzite is heated in the presence of carbon. This breaks the SiO2 into elemental silicon (Si) and carbon dioxide (C02). The silicon, however, still retains impurities originally in the quartzite. To remove most of these, an appropriate chemical vapor is blown over the silicon; the gas reacts with such impurities as aluminum, carbon, and magnesium, and they leave as part of the gas. After this process, the silicon still retains some impurities bad for a photovoltaic cell, so it is converted to a liquid called trichlorosilane (SiHCI3) using hydrogen chloride and a copper catalyst. The final purification of the silicon is then accomplished when trichlorosilane is distilled (much as are petroleum products), separating the SiHCl3 from the last impurities. Finally, the compound SiHCl3 is broken down and the pure silicon isolated by a slow, expensive, energy-intensive "chemical vapor deposition method" in which vaporized trichlorosilane is reacted with hydrogen gas, precipitating silicon. In total, this involved procedure raises the cost of silicon to about $70/kg; about 80% of this cost occurs in the last process, reducing trichlorosilane to a high-grade silicon.

Figure 4-1. A typical single-crystal silicon pnjunction solar cell.

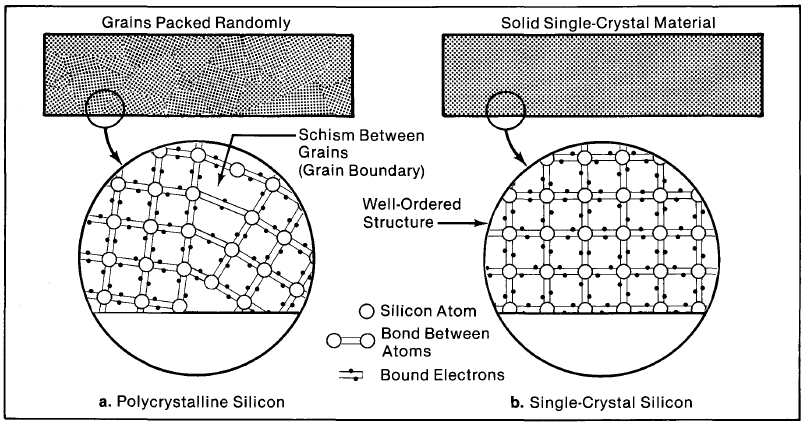

Figure 4-2. Purified silicon (a) is usually polycrystalline: It is made up of numerous single-crystal grains and electrically inhomogenous areas between them called grain boundaries. Single-crystal silicon (b) is structurally uniform and its electrical behavior is well understood.

This kind of silicon is a polycrystalline material (Figure 4-2a); that is, it is made up of numerous randomly packed "grains" of single-crystal silicon. To make effective solar cells, polycrystalline silicon must be processed into large-grained or single-crystal material (Figure 4-2b), the material used in the typical cell's base layer.

Making Single-Crystal Silicon

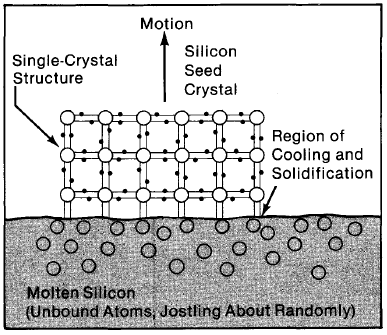

To turn polycrystalline silicon into single-crystal silicon, it must be melted and allowed to solidify in such a way that the silicon atoms arrange themselves in a perfect lattice (see Figure 4-2 and Chapter 2). This will happen naturally if the atoms of silicon are given time as they solidify to find their preferred positions (as opposed to being rapidly frozen wherever they happen to be). In general, the procedure is to cool the molten silicon very slowly while it is initially in contact with a single-crystal "seed" of silicon (Figure 4-3)

As the single-crystal silicon is grown, appropriate substances, or dopants, are introduced to make the base material behave electrically in the way necessary for solar cell operation. There are a number of dopants that can be used, but, in general, single-crystal silicon technologies have been developed for one combination -boron dopant in the base, phosphorus in the collector layer. (See Chapter 2 for the characteristics of these dopants.) Boron atoms can be introduced into the molten silicon before it solidifies as single-crystal material. As the silicon solidifies, the boron (acceptor) atoms assume places in the crystal structure that otherwise would be taken by silicon; this is the process whereby the silicon takes on its p-type electrical properties. A concentration of about 1016 atoms of added boron dopant per cubic centimeter exists in the final single-crystal material. This is about one boron atom for every million silicon atoms.

Figure 4-3. Molten silicon, solidifying in contact with a "starter" single-crystal seed, "grows" in a uniform manner, extending the single-crystal.

The above is a conceptual outline of single-crystal growth; but actual crystal growth takes many forms, each requiring different equipment and procedures. The two most established and dependable means of growing single-crystal silicon are the Czochralski process (Figure 4-4a) and the floating-zone technique (Figure 4-4b).

Figure 4-4. Converting polycrystalllne silicon to single-crystal silicon: (a) Czochralski growth apparatus and (b) floating-zone process.

The Czochralski Process. Here, a seed of single-crystal silicon contacts the top of a molten mass of purified silicon. The seed crystal is slowly raised (less than 10 centimeters per hour) and rotated. As the crystal rises imperceptibly from the melt, silicon freezes on its surface, extending the single-crystal structure. The final product is a cylindrical ingot, or "boule," typically 7.5 centimeters in diameter and many times that in length.

Controlling impurities is always a prime concern in making solar cells. In the Czochralski process, there are three processes that need to be managed:

- A wanted impurity, usually boron, is introduced in the molten silicon-it must be successfully transferred to the single-crystal silicon ingot.

- Unwanted impurities exist in the molten silicon, despite efforts to remove them during the previous purification steps-these unwanted impurities must be kept out of the crystal.

- The molten silicon is very susceptible to impurities that dissolve in it-especially those in contact with it because of the silica (SiO2) crucible holding the melt.

One reason that Czochralski-grown silicon is and has been a good material for solar cells is that the process naturally segregates impurities: that is, residual impurities in the molten mass of silicon tend to stay there rather than be incorporated into the crystal. (The large volume of molten silicon near the freezing region helps keep the impurities in the melt.) On the other hand, boron, which is the impurity that is needed for the cell to operate, is not segregated (as much) during Czochralski crystal growth; this felicitous behavior is the reason boron is most often chosen as a p-type dopant for silicon cells. One drawback of the Czochralski process, however, is that the SiO2 crucible in which the molten silicon is held loses some oxygen to the silicon, and this oxygen tends to move into the crystal in small, somewhat deleterious amounts. Also, at the end of each crystal "pull," the crucible cracks; a new pull requires a new crucible, adding to the process' cost.

The Floating-Zone Technique. This procedure requires an ingot of polycrystalline silicon and a seed crystal of single-crystal silicon. The polycrystalline ingot is placed atop the seed crystal and heated, causing the interface between the materials to become molten. While the ingot remains stationary, the heating coils are slowly raised. Single-crystal material solidifies below the molten interface and perpetuates upward as the heating coils move up. The technique is called "floating zone" because the region of molten silicon is unsupported; it maintains itself only by surface tension. The heating coils may be cycled up and down several times to assure total crystal uniformity, but this is not necessary for PV applications.

As with the Czochralski process, impurities are a concern with the floating-zone method. One relative disadvantage of the floating-zone technique is that it is less able to segregate impurities than the Czochralski process because the volume of molten silicon in which the rejected impurities are mixed is much less in the floating zone. On the other hand, the floating zone itself is not exposed to a silica (SiO2) crucible.

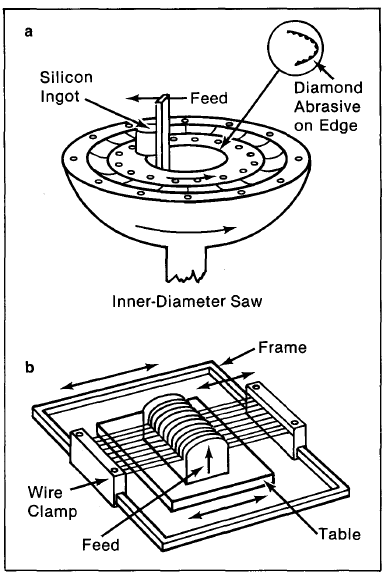

Making Wafers

Once ingots of single-crystal silicon have been made, they must be cut and processed into wafers, which then form the base layers of solar cells. The first step is to mill the ingot so that it is uniformly symmetric; this may take a few millimeters off the typically 7.5-centimeter-diameter ingot. The next step is to cut the ingots cross-sectionally with diamond saws (Figure 4-5a) or multiwire saws (Figure 4-5b). Wafers are typically 0.5 millimeters thick; unfortunately, saws are also about this thickness, so almost half the single-crystal material is lost during slicing. The wafers are then polished to diminish small-sized surface defects, which would otherwise interfere with light-generated charge carriers and diminish the cell's efficiency.

This completes an overview of the fabrication of a typical cell's base layer. Clearly, fabrication is an expensive, complex process. As we will see in the next chapter, much research and development is being done to simplify it and lower its costs.

Figure 4-5. Schematic of (a) innerdiameter saw, and (b) multiwire saw.

FORMING THE pn JUNCTION

Conceptually, a pn junction is formed when a layer of doped silicon is brought in contact with an oppositely doped base layer of silicon. In practice, the procedure is somewhat different. In our typical cell, for example, an n-doped surface layer is formed by coating the top of the base layer with phosphorus and heating (but not melting) the surface, which allows the phosphorus atoms to diffuse into the silicon. The temperature is then lowered, the rate of diffusion dropping to zero. The region in which the phosphorus penetrates becomes an n-type collector layer. Below the n-type layer is a very narrow transition region in which the dominant dopant switches from phosphorus (n-type donor) to boron (p-type acceptor)-this is the junction. Below this, the p-doped base material is unchanged, maintaining its p-type electrical character.

Figure 4-6 shows how the concentration of phosphorus varies as the phosphorus atoms diffuse into the silicon at 950oC. The concentration of the boron atoms in the base is about 1016 atoms per cubic centimeter. Enough phosphorus is coated on the surface to have a concentration of about 1021 atoms per cubic centimeter there. Heating the surface layer causes the phosphorus atoms to penetrate the base layer, but the concentration naturally drops off with depth There are 1018 atoms of phosphorus per cubic centimeter at a depth of 1.2 micrometers into the material, two orders of magnitude more than the concentration of boron atoms there. Thus the n-type character of the silicon extends to 1.2 micrometers. Below 1.2 micrometers is the junction region. Further into the cell, the base material maintains its p-type electrical behavior.

Figure 4-6. Four diffusion profiles for 950oC diffusions of phosphorus into silicon. Timing (10, 20, 30, or 60 minutes) can be regulated to produce the right amount and depth of dopant. The base layer doping is 2 × 1016 boron atorms/cm3. The model cell (above, right) shows that the junction region is located where the toplayer doping and the base-layer doping are equal.

Note the very high concentration of phosphorus at the surface. The number of phosphorus atoms there is about a hundredth of the number of silicon atoms. Given this situation, the phosphorus atoms no longer assume places in the silicon crystal-there are just too many phosphorus atoms present for this simple structure. Instead, the phosphorus and silicon form an alloy, eliminating the donor-type electrical behavior of the phosphorus atoms. Because of this, the heavily doped surface shows little resemblance to n-type silicon: It is highly resistive and causes much recombination. Called the "dead layer," it is the subject of much work to minimize its negative effects.

The thickness of the top, collector layer is of some importance. Solar cell efficiency is aided when light generates electrons and holes near the junction because then there is more likelihood that these charge carriers will be separated by the junction. As an illustration, consider this possibility: If the top surface is too thin, almost all the light will pass through it and be absorbed below the junction. On the other hand, if the front surface is properly designed, it can be made the right thickness to absorb about half the light, while the remaining light can be absorbed on the other side of the junction; this would minimize the average distance from the junction of the light-generated charge carriers. * All of this is oversimplified but suggests the parameters involved in designing a cell's front layer. In silicon, light absorption depends on wavelength (shorter wavelengths are absorbed more easily): Over 50% of the sunlight incident on silicon is absorbed within 3 micrometers of the surface, but it takes almost 300 micrometers in total to absorb all the rest of the sunlight. This would suggest a cell with a shallow junction (less than 3 micrometers), a thick base, and a high mobility of charge carriers in the base (because light-generated carriers may be formed far from the junction).

*Each incremental thickness of silicon has a certain constant probability of absorbing light and having an electron-hole pair generated. The thicker the substance, the more likely light will be absorbed.

ANTIREFLECTIVE COATINGS AND ELECTRICAL CONTACTS

A surface through which light passes has to be treated so that it reflects minimally, and electrical contacts have to be attached to a cell to collect charges.

Untreated silicon reflects more than 30% of the light incident on it. However, a measured layer of silicon monoxide (SiD), a very good antireflective coating, can easily be formed on a silicon cell. A single layer of SiO reduces a silicon cell's surface reflection to about 10%, while a double layer (with another substance) can reduce it to below 3%.

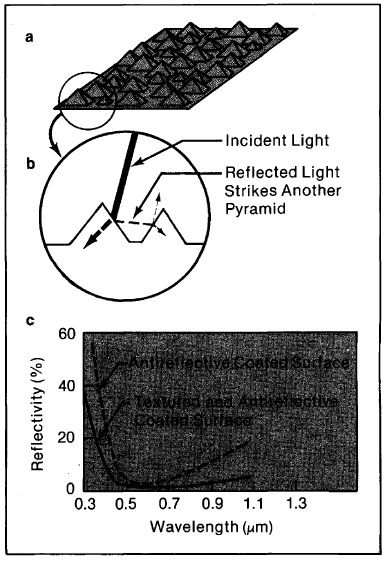

A further means to reduce reflection is to texture the top surface of a cell (Figure 4-7). Texturing causes reflected light to strike a second surface before it can escape, increasing the probability of absorption. For example, light with an 80% probability of being absorbed on one bounce (and therefore a 20% chance of being reflected) has a probability of being reflected twice or (0.2) × (0.2) = 0.04; i.e., its probability of absorption has been raised from 80% to 96% by the textured layer.

Figure 4-7. Texturing a cell exposes the tetrahedral surfaces of the silicon crystal lattice (a). Light that strikes the cell nearly perpendicularly (b) can either be absorbed or reflected; if it is reflected, it will strike another surface and have another chance to be absorbed. Note also that light that is absorbed is bent at the treated surface, so that it penetrates the cell obliquely. Because light travels through the cell at an angle, the cell need not be as thick to absorb as much light. The lower reflectivity (c) and the longer length the light travels through the cell give about a 15% improvement in cell efficiency over smooth, uncoated cells.

Electrical contacts must be attached to a cell for the cell to be placed in an electrical circuit. Design issues associated with contacts are similar to those associated with coated and textured surfaces. It would be best to completely cover the cell surfaces, back and front, with contacts; this would minimize the resistance that charge carriers experience. But, obviously, covering a cell with an opaque, metallic contact would completely block out the light. Thus a tradeoff must be made between resistance losses and shading effects. It is usual to design top-surface contacts as grids, with many thin conductive fingers spreading to every part of the cell's surface. The grid fingers must be thick enough to conduct well but thin enough not to block light. Such a grid keeps resistance losses sufficiently low, while shading only about 10% of the surface. Grids can be expensive to fabricate and can cause dependability problems. To make top-surface grids, metallic vapors can be deposited on a cell through a mask, or they can be painted on via a screen printing method. Attaching the back-surface contact to a cell is frequently not as complex: the contact simply can be a metal sheet. However, new cell designs [for concentrated light, for instance) may require that light enter the cell from the front and back, so that the back of the cell has to be treated antireflectively and have grid contacts, also.

Experiments are being conducted on alternative grid designs [such as putting them only on the cell's back surface) and on finding transparent grid materials, both of which are among the options examined in Chapter 5 on advanced silicon cells.

BIBLIOGRAPHY

Hovel, Harold J. 1975. Solar Cells. New York, NY: Academic Press; pp. 181-190.

Johnston, W.o., Jr. 1980. Solar Voltaic Cells. New York, NY: Marcel Dekker, Inc.; pp. 53-72.

Pulfrey, David L. 1978. Photovoltaic Power Generation. New York, NY: Van Nostrand Reinhold Co.; pp. 124-129.

Ravi, K.V. 1977. Journal of Crystal Growth. Vol. 39: p. 1.

Sittig, Marshall. 1979. Solar Cells for Photovoltaic Generation of Electricity. Park Ridge, NJ: Noyes Data Corp.; pp. 35-79, 126-149, 190-239.

Chapter 5

Advances in Single-Crystal

Silicon Solar Cells

HIGHLIGHTS

Progress aimed at making silicon cells more costeffective has advanced along two related fronts: new fabrication procedures and innovative cell designs.

Single-crystal silicon technology is well developed. One strategy for reducing cost is to fabricate the cells less expensively by using less-refined silicon and by making silicon ribbons that can be made directly into wafers without excessive material losses due to cutting. Edge-defined film-fed growth, ribbon-to-ribbon growth, and dendritic web growth are among the processes that result in ribbons.

High-performance silicon cells incorporate several innovative features. Back-surface fields are built-in fields that reflect minority carriers toward the junction, raising output voltage, current, and efficiency. Similar fields can be used at the front surface.

Schottky barrier cells are based on a junction effect that occurs at a metal-silicon contact. Their advantage is the elimination of the oppositely doped surface layer. Unfortunately, Schottky cells have exhibited less-than-adequate efficiency and are prone to degradation. Other designs that are being studied include metal-insulator-semiconductor (MIS) and semiconductor- insulator-semiconductor (SIS) cells, which are variations of the Schottky cell, and inversion layer cells.

Silicon cells for concentrated sunlight can be either single- or multijunction devices. Cooling is always necessary, since silicon performance drops rapidly with increasing temperature. Resistance losses are also critical; they are the main aspect attended to when designing a high-illumination cell. Grooved, multijunction cells have as much as 20% efficiency at 600 suns.

Other cell components and fabrication techniques are being researched. Laser-induced diffusion seems a promising alternative to thermal diffusion for junction formation. Antireflection layers are being optimized, especially via double layers and pyramidal texturing. Selective surfaces can lower heating effects. Polishing the back of a cell that has a textured front surface results in total internal light reflection, which allows cells to be thinner.

NEW FABRICATION

Silicon, as it is found in nature, is expensive to transform into single-crystal "wafers" for solar cells. Conventional methods for producing the material from which wafers are cut, the Czochralski and floatingzone techniques described in the previous chapter, "grow" single-crystal* silicon in ingots from molten silicon starting with single-crystal seeds; then the ingots are sawn into wafers. These are complex, expensive processes. New fabrication processes try to reduce expense by changing raw silicon into single-crystal silicon more cheaply, and by forming single-crystal silicon directly into usable wafers while avoiding steps such as sawing. Newer processes that incorporate this strategy by producing ribbons (long, thin, rectangular sheets) of single-crystal material include:

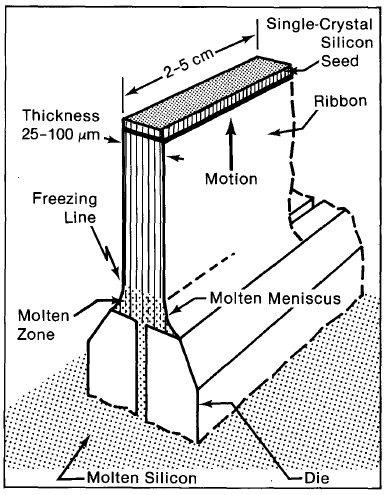

- Edge-defined film-fed growth (EFG)

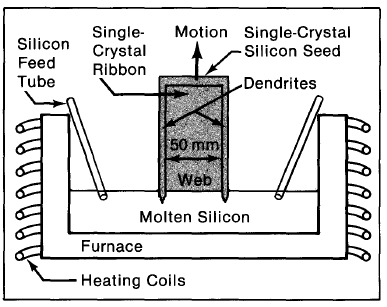

- Dendritic web growth

- Ribbon-to-ribbon (RTR) growth

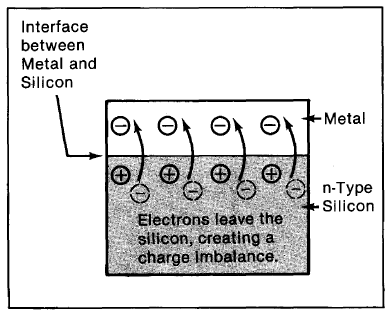

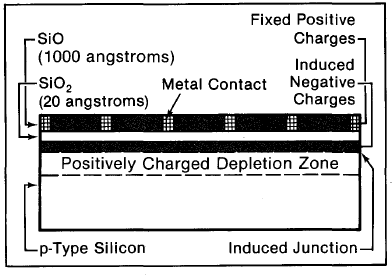

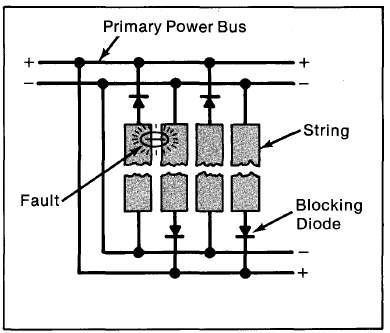

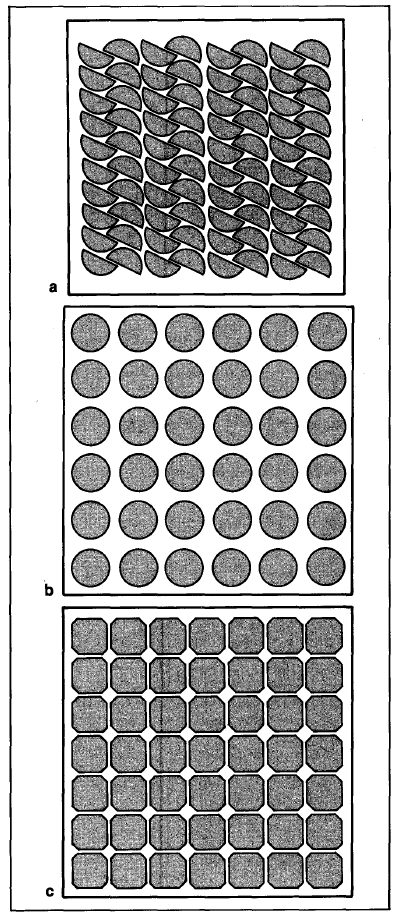

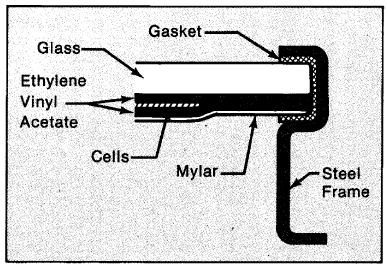

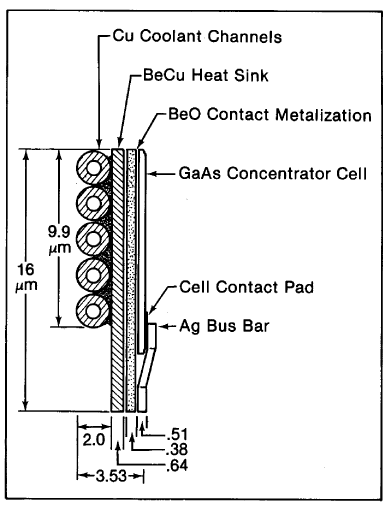

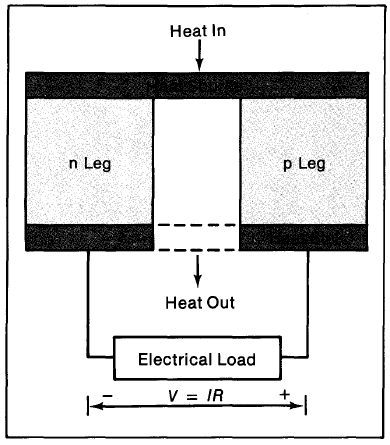

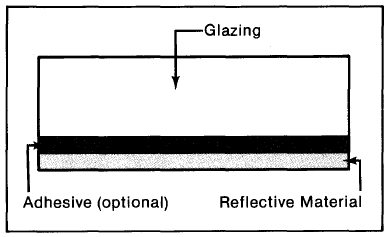

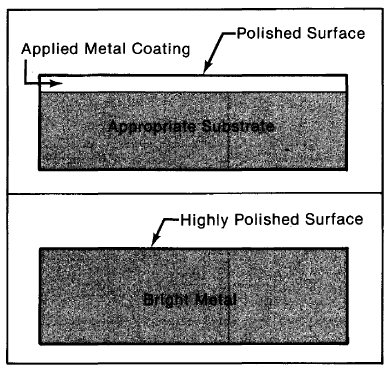

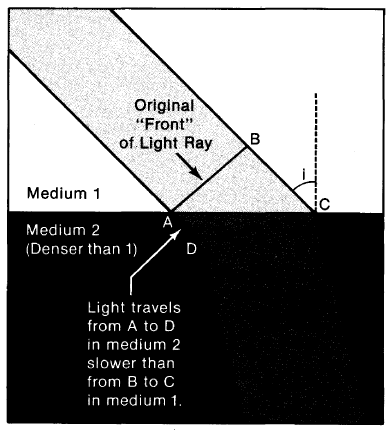

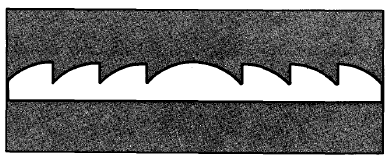

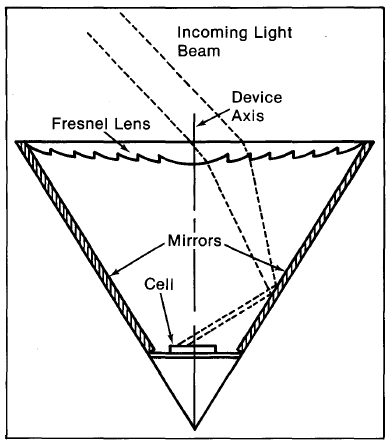

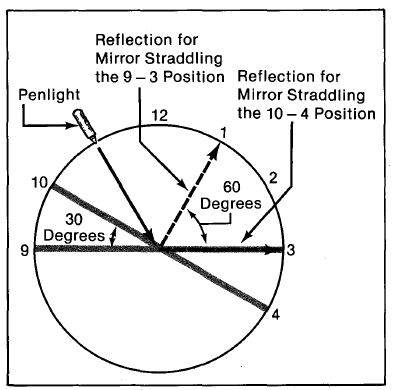

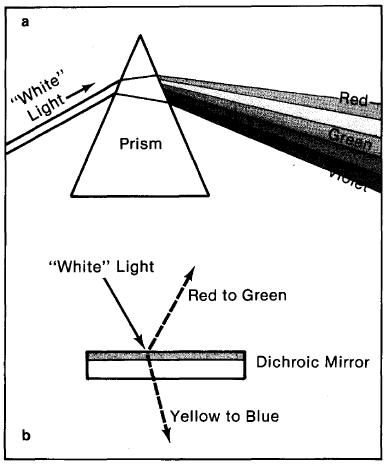

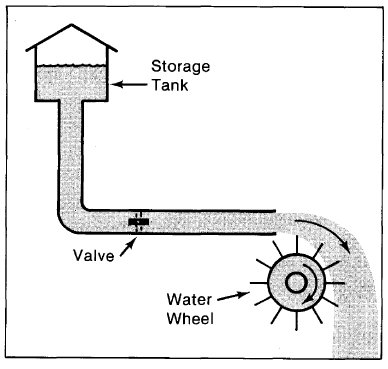

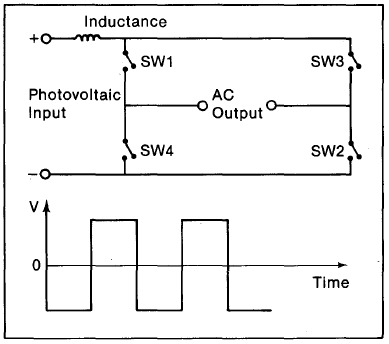

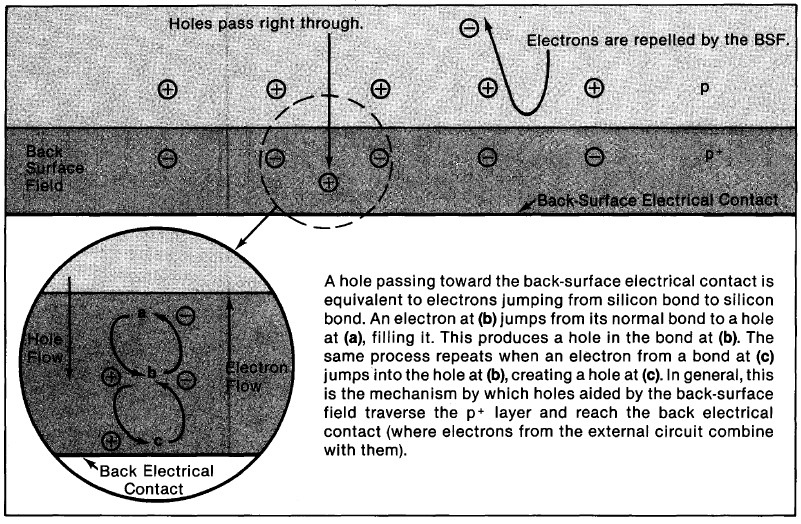

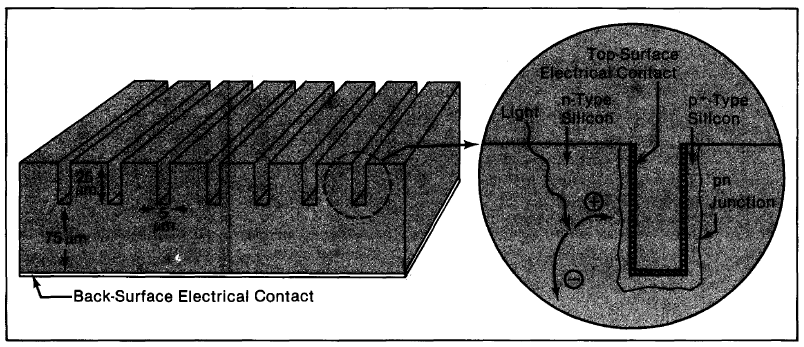

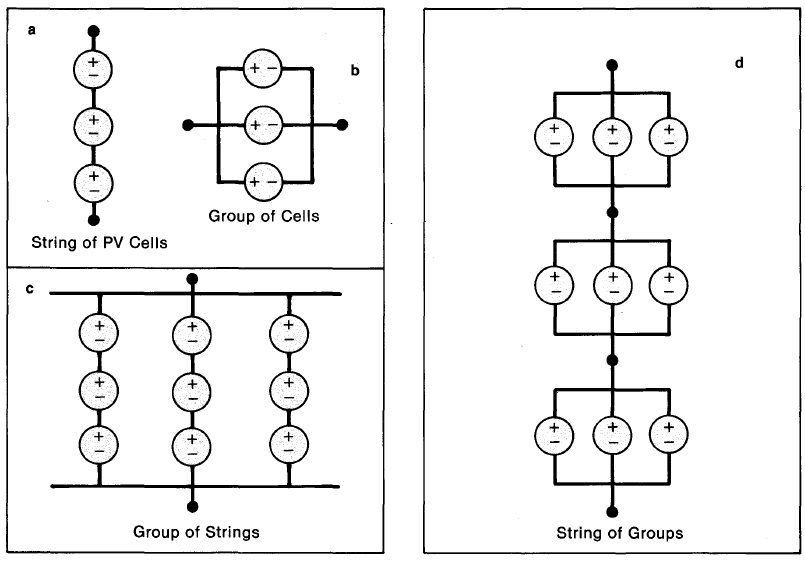

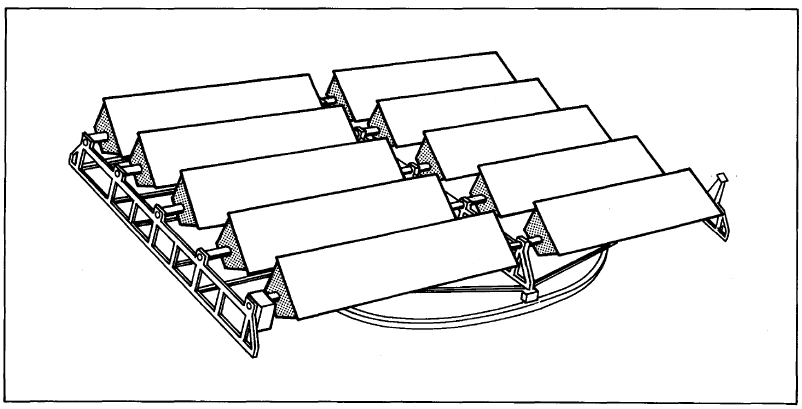

*The processes described in this chapter produce either single-crystal silicon or a similar material (large-grained polycrystalline silicon) with similar electrical properties. For purposes of simplicity, such material will simply be referred to as "single-crystal silicon."