Chiller Plant Design

Introduction

Using chilled water to cool a building or process is efficient and flexible. A two-inch Schedule 40 pipe of chilled water can supply as much comfort cooling as 42" diameter round air duct. The use of chillers allows the design engineer to produce chilled water in a central building location or even on the roof and distribute the water economically and without the use of large duct shafts. Chilled water also provides accurate temperature control that is especially useful for variable air volume (VAV) applications.

The purpose of this manual is to discuss various piping and control strategies commonly used with chilled water systems including variable flow pumping systems.

Using This Guide

| This Guide initially discusses the components used in a chilled water system. It then reviews various chiller plant designs explaining their operation, strengths and weaknesses. Where appropriate, sequence of operations are provided. Each project is unique so these sequences are just guidelines.

In addition, many sections reference ASHRAE Standard 90.1-2001. The ASHRAE section numbers are provided in parentheses to direct the reader. The sections referenced in this Guide are by no means complete. It is recommended that the reader have access to a copy of Standard 90.1 as well as the Users Manual. The Standard and manual can be purchased online at WWW.ASHRAE.org. |

|

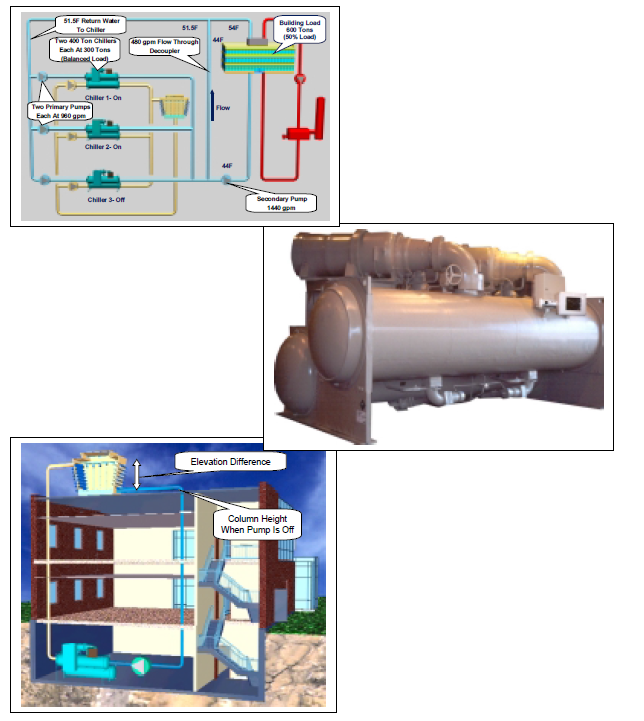

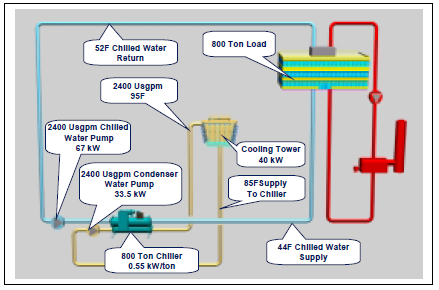

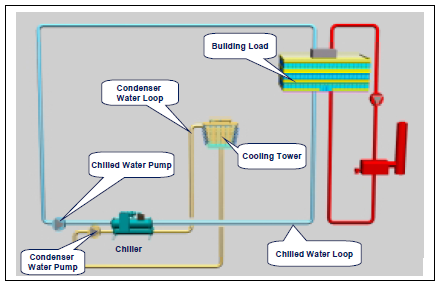

Basic System

Figure 1 shows a basic chiller loop with a water-cooled chiller. The system consists of a chiller, cooling tower, building cooling load, chilled water and condensing water pumps and piping. This section will review each of the components.

Figure 1 - Single Chiller Loop

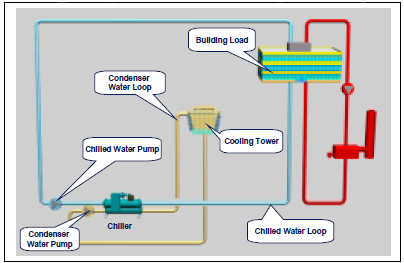

Chiller Basics

The chiller can be water-cooled, air-cooled or evaporatively cooled. The compressor types typically are reciprocating, scroll, screw or centrifugal. The evaporator can be remote from the condensing section on air-cooled units. This has the advantage of allowing the chilled water loop to remain inside the building envelope when using an outdoor chiller. In applications where freezing conditions can be expected, keeping the chilled water loop inside the building avoids the need for some form of antifreeze.

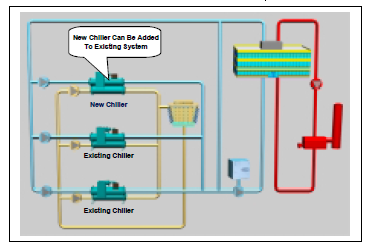

There can be multiple chillers in a chilled water plant. The details of various multiple chiller plant designs will be discussed in future sections.

The chilled water flows through the evaporator of the chiller. The evaporator is a heat exchanger where the chilled water gives up its sensible heat (the water temperature drops) and transfers the heat to the refrigerant as latent energy (the refrigerant evaporates or boils).

Flow and Capacity Calculations

For air conditioning applications, the common design conditions are 44oF supply water temperature and 2.4 gpm/ton. The temperature change in the fluid for either the condenser or the evaporator can be described using the following formula:

Q = W × C × ΔT

Where

Q = Quantity of heat exchanged (Btu/hr)

W = flow rate of fluid (USgpm)

C = specific heat of fluid (Btu/lb- oF)

ΔT = temperature change of fluid (oF )

Assuming the fluid is water, the formula takes the more common form of:

Load (Btu/hr) = Flow (USgpm) × (oFin - oFoutt) × 500

Or

Load (tons) = Flow (USgpm) × (oFin - oFout)/24

Using this equation and the above design conditions, the temperature change in the evaporator is found to be 10oF. The water temperature entering the evaporator is then 54oF.

Most air conditioning design conditions are based on 75oF and 50% relative humidity (RH) in the occupied space. The dewpoint for air at this condition is 55.08oF. Most HVAC designs are based on cooling the air to this dewpoint to maintain the proper RH in the space. Using a 10oF approach at the cooling coil means the supply chilled water needs to be around 44oF or 45oF.

The designer is not tied to these typical design conditions. In fact, more energy efficient solutions can be found by modifying the design conditions, as the project requires.

Changing the chilled water flow rate affects a specific chiller's performance. Too low a flow rate lowers the chiller efficiency and ultimately leads to laminar flow. The minimum flow rate is typically around 3 fps (feet per second). Too high a flow rate leads to vibration, noise and tube erosion. The maximum flow rate is typically around 12 fps. The chilled water flow rate should be maintained between these limits of 3 to 12 fps.

The condenser water flows through the condenser of the chiller. The condenser is also a heat exchanger. In this case the heat absorbed from the building, plus the work of compression, leaves the refrigerant (condensing the refrigerant) and enters the condenser water (raising its temperature). The condenser has the same limitations to flow change as the evaporator.

Chillers and Energy Efficiency

Chillers are often the single largest electricity users in a building. A 1000 ton chiller has a motor rated at 700 hp. Improving the chiller performance has immediate benefit to the building operating cost. Chiller full load efficiency ratings are usually given in the form of kW/ton, COP (Coefficient of Performance = kWcooling / kWinput) or EER (Energy Efficiency Ratio = Tons X 12/ kWinput). Full load performance is either the default ARI conditions or the designer specified conditions. It is important to be specific about operating conditions since chiller performance varies significantly at different operating conditions.

Chiller part load performance can be given at designer-specified conditions or the NPLV (Non- Standard Part Load Value) can be used. The definition of NPLV is spelled out in ARI 550/590-98, Test Standard for Chillers. For further information refer to McQuay Application Guide AG 31-002, Centrifugal Chiller Fundamentals.

☺Tip: To convert from COP to kW/ton;

COP = 3.516/(kW/ton)

To calculate EER = Tons x 12/(total kW input)

Figure 2 - ASHRAE Std 90.1 Chiller Performance Table1

Since buildings rarely operate at design load conditions (typically less than 2% of the time) chiller part load performance is critical to good overall chiller plant performance. Chiller full and part load efficiencies have improved significantly over the last 10 years (Chillers with NPLVs of 0.35 kW/ton are available) to the point where future chiller plant energy performance will have to come from chiller plant design.

ASHRAE Standard 90.1-2001 includes mandatory requirements for minimum chiller performance. Table 6.2.1.C of this standard covers chillers at ARI standard conditions. Tables 6.2.1H to M cover centrifugal chillers at non-standard conditions.

1 Copyright 2001, American Society Of Heating, Air-conditioning and Refrigeration Engineers Inc., www.ashrae.org. Reprinted by permission from ASHRAE Standard 90.1-2001

Piping Basics

Static Pressure

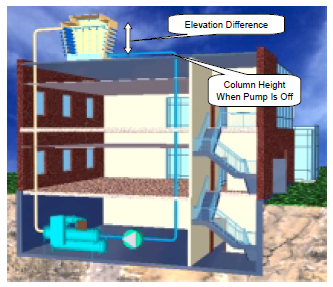

Figure 3 - Closed Loop

The piping is usually steel, copper or plastic. The chilled water piping is usually a closed loop. A closed loop is not open to the atmosphere. Figure 3 shows a simple closed loop with the pump at the bottom of the loop. Notice that the static pressure created by the change in elevation is equal on both sides of the pump. In a closed loop, the pump needs only to overcome the friction loss in the piping and components. The pump does not need to "lift" the water to the top of the loop.

When open cooling towers are used in condenser piping, the loop is an open type. Condenser pump must overcome the friction of the system and "lift" the water from the sump to the top of the cooling tower. Figure 4 shows an open loop. Notice the pump need only overcome the elevation difference of the cooling tower, not the entire building.

☺ Tip: Most chillers are rated for 150 PSI

water side pressure. This should be considered

carefully for buildings over 10 stories.

In high-rise applications, the static pressure can become considerable and exceed the pressure rating of the piping and the components such as chillers. Although chillers can be built to higher pressure ratings (The standard is typically 150 PSI but the reader is advised to check with the manufacturer) high pressure systems can become expensive. The next standard rating is typically 300 PSI. Above that, the chillers become very expensive. One solution is to use heat exchangers to isolate the chillers from the static pressure. While this solves the pressure rating for the chiller, it introduces another device and another approach that affects supply water temperature and chiller performance. A second solution is to locate chiller plants on various floors throughout the building selected to avoid exceeding the 150 PSI chiller rating.

Figure 4 -Open Loop

Figure 5 - Expansion Tank Location

The pressure at which the tank is operated is the reference point for the entire hydronic system. The location of the tank -which side on the pump (suction or discharge) - will affect the total pressure seen by the system. When the pump is off, the tank will be exposed to the static pressure plus the pressure due to thermal expansion. If the tank is located on the suction side, when the pump is running, the total pressure seen on the discharge side will be the pressure differential, created by the pump, added to the expansion tank pressure. If the expansion tank is located on the discharge side of the pump, the discharge pressure will be the same as the expansion tank pressure and the suction side pressure will be the expansion tank pressure minus the pump pressure differential.

Piping Insulation

Chilled water piping is insulated since the water and hence the piping is often below the dewpoint temperature. Condensate would form on it and heat loss would occur. The goal of the insulation is to minimize heat loss and maintain the outer surface above the ambient air dewpoint.

Condenser Water Piping

In most cases, the condenser water piping is an open loop. Figure 4 shows an open loop with the water open to the atmosphere. When the pump is not running, the level in the supply and return piping will be even at the level of the sump. When the pump operates, it needs to overcome the friction loss in the system and "lift" the water from the sump level to the top of the loop. Condenser water piping is typically not insulated since there will be negligible heat gain or loss and sweating will not occur. If the piping is exposed to cold ambient conditions, however, it could need to be insulated and heat traced to avoid freezing.

Reverse Return/Direct Return Piping

Figure 6 - Reverse Return Piping

Figure 6 shows reverse return piping. Reverse return piping is designed such that the path through any load is the same length and therefore has approximately the same fluid pressure drop. Reverse return piping is inherently self-balancing. It also requires more piping and consequently is more expensive.

Figure 7 - Direct Return Piping

Direct return piping results in the load closest to the chiller plant having the shortest path and therefore the lowest fluid pressure drop. Depending on the piping design, the difference in pressure drops between a load near the chiller plant and a load at the end of the piping run can be substantial. Balancing valves will be required. The advantage of direct return piping is the cost savings of less piping.

For proper control valve selection, it is necessary to know the pressure differential between the supply and return header (refer to Control Valve Basics, page 20). While at first it would appear with reverse return piping, that the pressure drop would be the same for all devices, this is not certain. Changes in pipe sizing in the main headers, different lengths and fittings all lead to different pressure differentials for each device. When the device pressure drop is large relative to piping pressure losses, the difference is minimized.

In direct return piping, the pressure drops for each device vary at design conditions depending on where they are in the system. The valve closest to the pumps will see nearly the entire pump head. Valves at the furthest end of the loop will see the minimum required pressure differential. Assuming the pressure differential sensor is located at the furthest end, all valves in a direct return system should be selected for the minimum pressure differential. This is because if any one device is the only one operating, the pressure differential controller will maintain the minimum differential across that device.

The decision whether to use direct or reverse return piping should be based on system operability vs. first cost. Where direct return piping is used, flow-balancing valves should be carefully located so that the system can be balanced.

Piping and Energy Efficiency

Piping materials and design have a large influence on the system pressure drop, which in turn affects the pump work. Many of the decisions made in the piping system design will affect the operating cost of the chiller plant every hour the plant operates for the life of the building. When viewed from this life cycle point of view, any improvements that can lower the operating pressure drop should be considered. Some areas to consider are:

| □ | Pipe material. Different materials have different friction factors. |

| □ | Pipe sizing. Smaller piping raises the pressure drop. This must be balanced against the capital cost and considered over the lifetime of the system. |

| □ | Fittings. Minimize fittings as much as possible. |

| □ | Valves. Valves represent large pressure drops and can be costly. Isolation and balancing valves should be strategically placed. |

| □ | Direct return vs. Reverse return. |

Piping insulation reduces heat gain into the chilled water. This has a compound effect. First, any cooling effect that is lost due to heat gain is additional load on the chiller plant. Second, in most cases, to account for the resultant temperature rise, the chilled water setpoint must be lowered to provide the correct supply water temperature at the load. This increases the lift on the chillers and lowers their performance.

ASHRAE 90.1-2001 requires the following for piping systems:

| □ | Piping must be insulated as per ASHRAE Standard 90.1 Table 6.2.4.1.3. (See Table 1) |

Exceptions include:

| □ | Factory installed insulation. |

| □ | Systems operating between 60oF and 105oF. |

| □ | The hydronic system be proportionally balanced in a manner to first minimize throttling losses and then the impeller trimmed or the speed adjusted to meet the design flow conditions (6.2.5.3.3) |

Exceptions include:

| □ | Pumps with motors less than 10 hp. |

| □ | When throttling results in no greater than 5% of nameplate horsepower or 3 hp, whichever is less. |

| □ | Three pipe systems with a common return for heating and cooling are not allowed. (6.3.2.2.1) |

| □ | Two pipe changeover systems are acceptable providing: (6.3.2.2.2) |

| □ | Controls limit changeovers based on 15oF ambient drybulb deadband. |

| □ | System will operate in one mode for at least 4 hours. |

| □ | Reset controls lower the changeover point to 30oF or less. |

| □ | Systems with total pump nameplate horsepower exceeding 10 hp shall be variable flow able to modulate down to 50%. (6.3.4) |

Table 1 - Minimum Piping Insulation As Per Std 90.12

| Fluid Design Operating Temp. Range (oF) |

Insulation Conductivity | Nominal Pipe or Tube Size (in) | |||||

| Conductivity Btu•in/(h•ft2•oF) |

Mean Rating Temp oF |

<1 | 1 to <1-1/2 | 1-1/2 to <4 | 4<8 | >8 | |

| Cooling Systems (Chilled Water, Brine and Refrigerant) | |||||||

| 40-60 | 0.22-0.28 | 100 | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 |

| >60 | 0.22-0.28 | 100 | 0.5 | 1.0 | 1.0 | 1.0 | 1.5 |

Pumping Basics

Figure 8 - Inline Centrifugal Pump

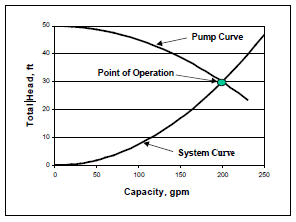

Figure 9 - Basic Pump Curve

2 Copyright 2001, American Society Of Heating, Air-conditioning and Refrigeration Engineers Inc., www.ashrae.org. Reprinted by permission from ASHRAE Standard 90.1-2001

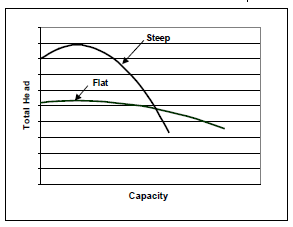

Figure 10 - Pump Curve Profiles

Figure 11 - Typical Centrifugal Pump Curve

☺Tip: For a constant system curve, the following

pump affinity laws may be used;

At constant impeller diameter (Variable speed)

RPM1 / RPM2 = gpm1 / gpm2 = (H1 )1/2/(H2 )1/2

At constant speed (Variable impeller diameter)

D1 / D2 = gpm1 / gpm2 = (H1 )1/2/(H2 )1/2

Figure 11 shows a typical pump curve. Since pumps are direct drive, the pump curves are typically for standard motor speeds (1200, 1800 or 3600 rpm). The required flowrate and head can be plotted and the subsequent efficiency and impeller diameter can be found. As the flow increases, generally the Net Positive Suction Head (NPSH) decreases. This is due to the increased fluid velocity at the inlet of the impeller. NPSH is required by the pump to avoid the fluid flashing to gas in the inlet of the impeller. This can lead to cavitation and pump damage. NPSH is an important consideration with condenser pumps particularly when the chillers are in the penthouse and the cooling towers are on the same level.

Multiple Pumps

To provide redundancy, multiple pumps are used. Common approaches are (1) a complete full-sized stand-by pump, or (2) the design flow is met by two pumps with a third stand-by pump sized at half the load. When multiple pumps are used in parallel, check valves on the discharge of each pump are required to avoid "short circuiting". Pumps can also utilize common headers to allow one pump to serve multiple duties (headered primary pumps serving multiple chillers). Refer to Primary Pumps, page 52 for more information on primary pumps.

Variable Flow Pumps

Many applications require the flow to change in response to load. Modulating the flow can be accomplished by:

| □ | Riding the pump curve |

| □ | Staging on pumps |

| □ | Using variable frequency drives (VFDs) |

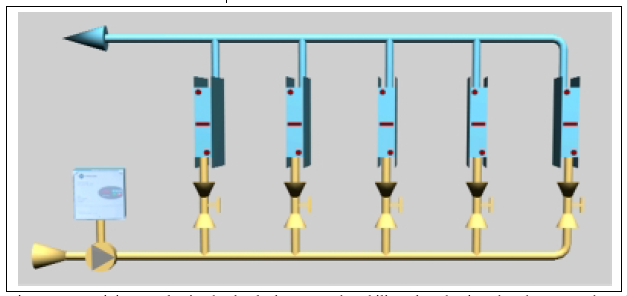

Riding the pump curve is typically used on small systems with limited flow range. Staging on pumps was the traditional method until VFDs. Today, VFDs are the most common method for varying flow. They are the most efficient method as well. System flow is usually controlled by maintaining a pressure differential between the supply and return lines. The measuring point should be at or near the end of the pipe runs as opposed to being in the mechanical room to reduce unnecessary pump work. This is particularly true for direct return systems.

☺Tip: The differential pressure setpoint for variable

flow pumps should based on field measurements taken

during commissioning and balancing. Using an

estimated setting may lead to unnecessary pump work

for the life of the building

Figure 12 shows the differential pressure sensor located at the end of the piping run. At design load, the pressure drop across coil 1 is 60 ft while the pressure drop across coil 5 is only 30 ft. Then differential pressure controls should be set up to maintain 30 ft. When only coil 1 is operating, the pressure differential across coil 1 will only be 30 ft if the differential sensor is located at the end of the run as shown. If the sensors had been near the pumps, however, the differential controller would have to have been set for 60 ft to meet the design requirements. When only coil 1 operates, the pressure would have been maintained at 60 ft, which would have wasted pump work.

Figure 12 - Secondary Pump Control in Direct Return Systems

Another method of controlling variable flow pumps is to monitor the valve positions of a control valve in a critical part of the system. This valve is typically the furthest from the pumps. The control system then maintains the minimum pressure differential necessary, which allows the valve to maintain setpoint. The advantage of this approach is the system pressure is maintained at the minimum required to operate properly and that translates into minimum pump work.

When multiple pumps are required to be variable flow, such as the secondary pumps of a primarysecondary system, VFDs are recommended on all pumps. Consider a system with two equal pumps, both are required to meet the design flow. Pump 1 has a VFD while pump 2 does not. From 0 to 50% flow, pump 1 can be used with its VFD. Above 50%, the second pump will be required. When pump 2 is started, it will operate at design speed. It will overpower pump 1, which will need to operate at less than design speed and will not generate the same head.

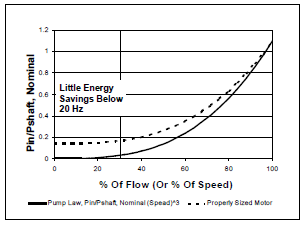

Figure 13 - Pumping Power vs. Flow3

Pumps and Energy Efficiency

Pump work is deceptive. Although the motors tend to be small (when compared to chiller motors), they operate whenever the chiller operates. In a single water-cooled chiller plant with constant chilled water flow, it is not unusual for the pumps to use two-thirds of the energy consumed by the chiller. Optimal use of pumps can often save more energy than any other improvement to a chiller plant.

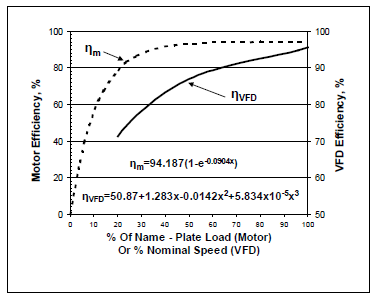

Figure 14 - Motor and VFD Efficiency At Part Load

3 Bernier, Michel., Bernard Bourret, 1999. Pumping Energy and Variable Speed Drives. ASHRAE Journal, December 1999. ASHRAE. Atlanta, Ga.

ASHRAE 90.1-2001 requires the following for pumps:

| □ | The hydronic system be proportionally balanced in a manner to first minimize throttling losses and then the impeller trimmed or the speed adjusted to meet the design flow conditions (6.2.5.3.3) |

Exceptions include:

| □ | Pumps with motors less than 10 hp. |

| □ | When throttling results in no greater than 5% of nameplate horsepower or 3 hp, whichever is less |

| □ | Systems with total pump nameplate horsepower exceeding 10 hp shall be variable flow able to modulate down to 50%. (6.3.4) | |

| □ | Individual pumps with over 100- head and a 50-hp motor shall be able to operate at 50% flow with 30% power. | |

| □ | The differential pressure shall be measured at or near the furthest coil or the coil requiring the greatest pressure differential. | |

| Exceptions include: | ||

| □ | Where minimum flow interferes with proper operation of the equipment (i.e., the chiller) and the total pump horsepower is less than 75. | |

| □ | Systems with no more than 3 control valves. | |

Cooling Tower Basics

Cooling towers are used in conjunction with water-cooled chillers. Air-cooled chillers do not require cooling towers. A cooling tower rejects the heat collected from the building plus the work of compression from the chiller. There are two common forms used in the HVAC industry: induced draft and forced draft. Induced draft towers have a large propeller fan at the top of the tower (discharge end) to draw air counterflow to the water. They require much smaller fan motors for the same capacity than forced draft towers. Induced draft towers are considered to be less susceptible to recirculation, which can result in reduced performance.

Figure 15 - Induced Draft Cooling Tower

Forced draft towers have fans on the air inlet to push air either counterflow or crossflow to the movement of the water. Forward curved fans are often employed. They use more fan power than induced draft but can provide external static pressure when required. This can be important if the cooling tower requires ducting, discharge cap or other device that creates a pressure drop.

Condenser water is dispersed through the tower through trays or nozzles. The water flows over fill within the tower, which greatly increases the air-to-water surface contact area. The water is collected into a sump, which can be integral to the tower or remote from the tower. The latter is popular in freezing climates where the condenser water can be stored indoors.

Either tower type can have single or multiple cells. The cells can be headered together on both the supply and return side with isolation valves to separate the sections. This approach allows more cells to be added as more chillers are activated or to allow more tower surface area to be used by a single chiller to reduce fan work.

Typical Operating Conditions

The Cooling Tower Institute (CTI) rates cooling towers at 78oF ambient wetbulb, 85oF supply water temperature and a 10oF range. Since it is common (but not necessary) to use a temperature range of 10oF, the cooling tower flow rate will be 3.0 gpm/ton compared to the chilled water flow rate which is 2.4 gpm/ton. The extra condenser water flow rate is required to accommodate the heat from the work of compression. Cooling towers are very versatile and can be used over a wide range of approaches, ranges, flows and wetbulb temperatures. Lower condenser water temperatures can be produced in many climates with low wet bulb temperatures which significantly improves chiller performance.

Figure 16 - Forced Draft Cooling Tower

Cooling Tower Process

Cooling towers expose the condenser water directly to the ambient air in a process that resembles a waterfall. The process can cool condenser water to below ambient drybulb. The water is cooled by a combination of sensible and latent cooling. A portion of the water evaporates which provides the latent cooling. The example on page 18 shows the cooling tower process on a psychrometric chart at ARI conditions. As the wetbulb temperature drops, cooling towers rely more on sensible cooling and less on latent cooling. Ambient air below freezing can hold very little moisture which leads to large plumes; and in some cases the winter tower selection requires a larger tower than the summer conditions. Additional care should be taken when selecting cooling towers for use in winter.

The above psychrometric chart shows the cooling tower process at ARI conditions. Assume 1 lb. of water is cooled by 1 lb. of air. The water cools from 95oF to 85oF and releases 10 Btus of heat to the air ( 1 Btu = the amount of heat required to raise the temperature of 1 lb. of water, 1oF). The 10 Btus of heat raises the enthalpy of air from 42.4 Btu/lb. to 52.4 Btu/lb. and saturates the air. The leaving air condition is 87.5oF and 100% RH. The moisture content went from 0.018 lb.w to 0.029 lb.w. This means 0.029- 0.018 lb. = 0.011 of water was evaporated which is why it is common to hear that cooling towers lose about 1% of their water flow to evaporation. The latent heat of vaporization for water at 85oF is about 1045 Btu/lb. Multiplying the latent heat times the amount of evaporated water (1045 × 0.011) results in 11.45 Btus of cooling effect. Cooling the water required 10 Btus, the rest was used to cool the air sensibly. The air entered the tower at 95oF and left the tower at 87.5oF.

Approximately 1% of the design condenser water flow is evaporated (See the above example). A 1000-ton chiller operating at design conditions can consume 1800 gallons of water per hour. The specific amount can be calculated by reviewing the psychrometric process. In locations where the cost of water is an issue, air-cooled chillers may provide a better operating cost despite the lower chiller performance.

Winter Operation

Cooling towers required to work in freezing winter environments require additional care. The condenser water must not be allowed to freeze particularly when the tower is idle. Common solutions include electric or steam injection heaters or a remote sump within the building envelope. The high RH of ambient winter air results in a plume, which can frost over surrounding surfaces. Low plume towers are available. Finally, freezing of condenser water on the tower itself can lead to blockage and reduced or no performance. Modulating water flow through a cooling tower (such as the use of threeway chiller head pressure control) should be given careful consideration. In many instances this can lead to increased possibility of freezing the tower.

Water Treatment

Condenser water has all the right ingredients for biological growth; it is warm, exposed to air and provides surfaces to grow on. In addition, the constant water loss makes water treatment even more difficult. Both chemical and ozone-based treatment systems are used. A thorough discussion on the topic of water treatment is beyond the scope of this Guide but it suffices to say, that it is necessary to provide the proper operation of both the tower and the chiller.

Closed Circuit Coolers

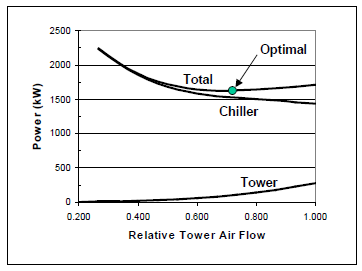

Figure 17 - Chiller Power Vs. Tower Power4

Cooling towers differ from closed-circuit coolers in that closed-circuit coolers reject heat sensibly while cooling towers reject heat latently. Consider ambient design conditions of 95oF DB and 78oF wb. If closed circuit coolers are used, the condenser water must be warmer than the ambient drybulb (typically 10oF warmer or 105oF). This raises the condensing pressure in the chiller and requires more overall power for cooling. Closed circuit coolers are larger than cooling towers for the same capacity and can be difficult to locate on the roof.

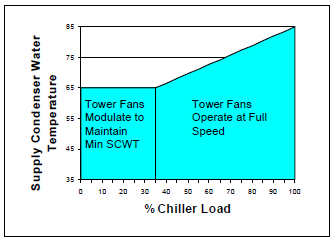

Cooling Tower Controls

Cooling tower controls provide condenser water at the correct temperature to the chillers. Defining correct water temperature is very important. Lowering the condenser supply water temperature (to the chiller) increases the effort by the cooling tower and more fan work can be expected. It also improves the chiller performance. Figure 17 shows the relationship between chiller and tower work.

Table 2 - Chiller Performance Vs. CSWT

| Chiller Type | Performance Improvement (Percent kW /oF condenser water) |

| W/C Recip. | 1.1 to 1.3 |

| W/C Scroll | 1.3 to 1.5 |

| W/C Screw | 1.6 to 1.8 |

| W/C Centrifugal | 1.0 to 1.6 |

| W/C Centrifugal VFD | 2.4 to 2.6 |

| Absorption | 1.4 to 1.5 |

Table 2 shows the range of chiller improvement that can be expected by lowering the condenser water supply temperature. The goal of cooling tower control is to find the balance that provides the required cooling with the least use of power by the chiller plant.

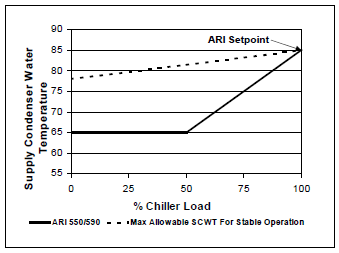

Cooling towers are often provided with aquastats. This is the most basic level of control. They are popular for single chiller-tower arrangements because the control package can be supplied as part of the cooling tower. The aquastat is installed in the supply (to the chiller) side of the cooling tower. In many cases, the setpoint is 85oF, which is very poor.

Figure 18 shows the 85oF setpoint and the ARI condenser relief curve which chillers are rated at. Maintaining 85oF condenser water, while saving cooling tower fan work, will significantly penalize the chiller. There is some risk that without some condenser relief, the chiller may not operate at lower part load conditions (The chiller may surge).

4 Braun, J.E., and G.T. Diderrich. 1990. Near-Optimal Control of Cooling Towers For Chilled Water Systems. ASHRAE Transactions SL-90-13-3, Atlanta, Ga.

Figure 18- Chiller Performance with 85 T Setpoint

Figure 19 - Chiller Performance with Minimum Setpoint

☺Tip: Using wetbulb plus tower design approach as

a setpoint can strike an excellent balance between

chiller work and cooling tower fan work.

A method to control either single cell or multiple cell cooling towers serving multiple chillers is to base the condenser supply water temperature on ambient wetbulb. For this method, set the condenser water setpoint at the current ambient wetbulb plus the design approach temperature for the cooling tower. The set-point will change as the ambient wetbulb changes. Limit the setpoint between the design condenser water temperature (typically 85oF) and the minimum condenser water temperature (typically 65oF).

The wetbulb method will provide good condenser relief for the chiller and cooling tower fan work relief when the chiller is not operating at 100% capacity. It can be a good balance between chiller and tower work.

Ultimately, the best cooling tower control designs are part of a chiller plant optimization program. These programs monitor the weather, the building load and the power consumption of all the components in the chiller plant including cooling towers. Using modeling algorithms, the program calculates the best operating point to use the least power possible and meet the requirements of the building.

Cooling Towers and Energy Efficiency

Cooling towers consume power to operate the fans. Induced draft towers should be selected since they typically use half the fan horsepower force draft towers use. Some form of fan speed control is also recommended such as piggyback motors, multi-speed motors or Variable Speed Drives (VFDs). In addition, a sensible controls logic is required to take advantage of the variable speeds.

ASHRAE 90.1-2001 requires the following for heat rejection devices:

| □ | Requires fan speed control for each fan motor 7 1/2 hp or larger. The fan must be able to operate at two-thirds speed or less and have the necessary controls to automatically change the speed. (6.3.5.2) |

| Exceptions include: | |

| □ | Condenser fans serving multiple refrigeration circuits. |

| □ | Condenser fans serving flooded condensers |

| □ | Installations in climates with greater than 7200 CDD50. |

| □ | Up to one-third of the fans on a condenser or tower with multiple fans, where the lead fans comply with the speed control requirement. |

Load Basics

Figure 20 -Air Handling Equipment

Chilled water coils are used to transfer the heat from the building air to the chilled water. The coils can be located in air handling units, fan coils, induction units, etc. The air is cooled and dehumidified as it passes through the coils. The chilled water temperature rises during the process.

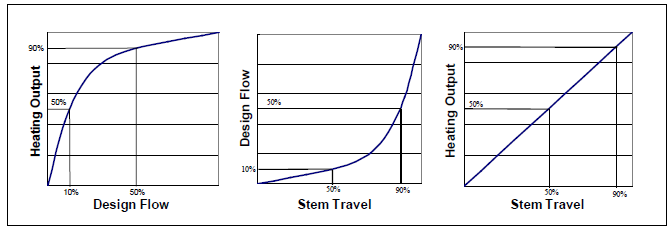

Cooling coil performance is not linear with flow. Cooling coils perform 75% cooling with only 50% chilled water flow and 40% cooling with only 20% flow. As well, the leaving water temperature will approach the entering air temperature as the load is reduced.

Process loads can reject heat in the chilled water in a variety of ways. A common process load is a cooling jacket in machinery such as injection molding equipment. Here the chilled water absorbs the sensible heat of the process.

Control Valve Basics

Control valves are used to maintain space temperature conditions by altering chilled water flow. Valves can be broken down into groups in several ways. Valves can be two-position or modulating. Two-position valves are either on or off. Control comes from time weighting. The percentage that the valve is open over a certain time period dictates the amount of cooling that the cooling coil actually does. Modulating valves vary the flow in response to the actual load at any given time.

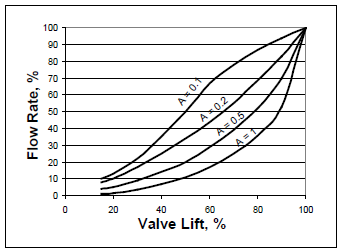

Valves can also be classified as two-way or three-way type. Two-way valves throttle flow while three divert flow. Refer to Piping Diversity, page 24 for further explanation. There are several different physical types of valves. Globe valves, ball valves and butterfly valves are all commonly used in the HVAC industry.

Figure 21 - Coil and Control Valve Performance Curves

Different kinds of valves have different valve characteristics. Common characteristic types include linear, equal percentage and quick opening. Control valves used with cooling coils need to have a performance characteristic that is "opposite" to the coil. Equal percentage control valves are typically used for two-way applications. For three-way applications, equal percentage is used on the terminal port and linear is used on the bypass port.

Figure 21 shows an equal percentage control valve properly matched to a cooling coil. The result is that the valve stem movement is linear with the cooling coil capacity. In other words, a valve stroked 50% will provide 50% cooling.

Sizing Control Valves

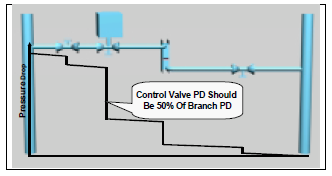

Control valves must be sized correctly for the chilled water system to operate properly. An incorrectly sized control valve cannot only mean the device it serves will not operate properly, it can also lead to system-wide problems such as low delta T syndrome.

Control valves are typically sized based on the required Cv . The Cv is the amount of 60oF water that will flow through the valve in US gpm, with a 1 PSI pressure drop. The formula is:

G = Cv (ΔP)1/2

Where:

G is the flow through the valve in US gpm

Cv is the valve coefficient.

ΔP is the differential pressure required across the control valve.

The required flow at a control valves is defined by the needs on the device (fan coil, unit ventilator or AHU) it serves. Cv values for valves are published by valve manufacturers. The required pressure differential through the valve is the difficult parameter to define.

Figure 22 - Pressure Drops and Cv

Valve Authority

☺Tip: When calculating valve C to size valves, use at

least 50% of the system pressure drop from the supply to

the return line to maintain good valve authority. In most

cases, a properly sized control valve will be smaller than

the line size it is installed in.

As a control valve closes, the pressure drop across the valve increases so that when the valve is completely closed, the differential pressure drop across the valve matches the pressure drop from the supply to the return line. This pressure drop is known as ΔPMax. When the valve is completely open, the pressure drop across the valve is at its lowest point and is referred to ΔPMin. The ratio (β) ΔPMin / ΔPMax is the valve authority. The increase in pressure drop across the valve as it closes is important to note. Valves are rated based on a constant pressure drop. As the pressure drop shifts, the performance of the valve changes. The method to minimize the change in valve performance is to maintain the Valve Authority (β) above 0.5.

Figure 23 - Distortion of Equal Percentage Valve Characteristic

Valve Authority Example

Consider a control valve with a Cv = 25 serving a coil that has a design flow of 50 US gpm. The pressure differential from the supply to the return line is 16 PSI.

As the valve closes, the system pressure shifts to the valve until all the pressure drop (16 PSI) is across the valve. If the valve was fully opened and there was 16 PSI across the valve the flow rate would increase to:

Q = Cv (ΔP)1/2 = 25(16) 1/2 = 100 US gpm.

This does not actually happen, however, since the pressure drop through the coil, balancing valve, etc. increases and limits flow to 50USgpm.

ΔPMin = (Q)2/( C2)2 = (50)2/( 25)2 = 4 PSI

In this case, the valve authority (β) is 4 PSI/16 PSI = 0.25. Referring to Figure 23, it can be seen that the valve performance characteristic is distorted and when matched to a cooling coil will not provide a linear relationship between valve position and coil output. This can lead to poor coil performance and low delta T syndrome. The solution is to try and keep the valve authority above 0.5. In other words, the pressure drop though the control valve when it is fully open should be at least 50% of the pressure drop from the supply to return line.

Rangeablity

Rangeablity is a measure of the turndown a control valve can provide. The larger the range, the better the control at low loads. Typical ranges for control valves are 15:1 to 50:1.

Control Valve Location in Systems

Proper valve selection requires knowing the pressure drop from the supply to the return wherever the device is located. This information is typically not made available to the controls contractor which often leads to guessing. One solution would be for the designer to provide the required Cv for each valve. Another solution would be to provide the estimated pressure drops for each valve. Because the pressure drop from the supply to the return changes throughout the system, it can be expected that different valves with different Cvs will be required. Even if all the coil flows and pressure drops were identical, the valves should change depending on location in the system. Lack of attention to this detail can lead to low delta T syndrome (refer to Low Delta T Syndrome, page 80) that can be very difficult to resolve.

Loop Control Basics

There are two parameters that need to be considered for the chilled water loop. These are temperature and flow. The loop supply temperature is usually controlled at the chiller. The unit controller on the chiller will monitor and maintain the supply chilled water temperature (within its capacity range). The accuracy to which the chiller can maintain the setpoint is based on the chiller type, controller quality (a DDC controller with a PID loop is the best), compressor cycle times, the volume of fluid in the system, etc. Systems with fast changing loads (especially process loads) and small fluid volumes (close coupled) require special consideration.

The system flow control occurs at the load. To control the cooling effect at the load, two-way or three-way valves are used. Valve types are discussed in Control Valve Basics, page 20. Valve selection will also touch on piping diversity and variable vs. constant flow.

Another method to control cooling is face and bypass control at the air cooling coil while running chilled water through the coil. This approach has the advantage of improved dehumidification at part load and no waterside pressure drops due to control valves. The disadvantage is the requirement for continuous flow during any mechanical cooling load. In many cases the pressure drop savings will offset the continuous operation penalty but only annual energy analysis will clarify it. Face and bypass coil control is popular with unit ventilator systems with their required high percentage of outdoor air, and make-up air systems.

Piping Diversity

Figure 24 - Three-way Valves

Diversity in piping is based on what type of valves are used. To maintain the correct space condition, three-way or two-way control valves are used. Threeway control valves direct chilled water either through or around the coil to maintain the desired condition. If all the loads on the loop use three-way valves, then the chilled water flow is constant. The temperature range varies directly with the load. That is, if the design chilled water temperature range is 10oF, then every 10% drop in system load represents a 1oF drop in temperature range. A system incorporating three-way control valves is easy to design and operate. The system pumps all the water all the time, however this requires more pump horsepower. In most cases the chiller is sized for the building peak load. Due to diversity, not all the connected loads will "peak" at the same time as the building peak load. However, the pumps and piping system must be designed for full flow to all the control valves all the time. Since the chiller flow rate is the same as the flow rate through all the loads (they're connected by the same piping system and pump) the diversity is applied to the chiller temperature range.

Figure 25 - Two-Way Valves

For example, consider a building with an 80-ton peak load. Summing all the connected loads adds up to 100 tons. In short, this building has a diversity of 80%. Using a temperature range of 10oF at each control valve, the total system flow rate is:

Flow = 24 × 100 tons/10oF = 240 gpm

However, an 80-ton chiller with 240 gpm will only have a temperature range of 8oF. The lower chiller temperature range is not a problem for the chiller operation, but it will lower the chiller efficiency. Care must be taken to select the chiller at the proper temperature range.

When two-way modulating control valves are used, the flow to the coil is restricted rather than bypassed. If all the valves in the system are two-way type, the flow will vary with the load. If the valves are properly selected, the temperature range remains constant and the flow varies directly with the load. In this case the diversity is applied to the chilled water flow rate.

Using the previous example, the peak load is 80 tons and the design flow is 2.4 × 80 tons or 192 gpm. The connected load is still 100 tons and requires 240 gpm if all the two-way control valves are open at the same time. The 80% diversity assumes only 80% of the valves will be open at the peak load.

The advantage of two-way control valves is both the pump and the piping are sized for a smaller flow rate, offering both first cost and operating savings. The difficulty is that the chiller and control system must be designed for variable flow. The chiller has a minimum flow rate so the piping design has to allow for enough flow during all operating conditions to meet the chiller minimum flow rate. Using two-way valves is the main building block for a variable flow system.

Water Temperatures and Ranges

Selection of temperature ranges can affect the chiller plant operation and energy usage. The limiting temperatures are the required supply air temperature and either the ambient wetbulb (water or evaporatively cooled chillers) or drybulb (air cooled chillers) temperatures. Once these have been identified, the HVAC system must operate within them.

Supply Air Temperature

The chilled water supply temperature is tied to the supply air temperature. The chilled water temperature must be cold enough to provide a reasonable log mean temperature difference (LMTD) (Refer to McQuay , for more information on LMTD) for a cooling coil to be selected. Traditionally this has resulted in a 10oF approach which, when subtracted from 55oF supply air temperature, has led to the 44 or 45oF chilled water temperature. Lowering the chilled water temperature will increase the approach allowing a smaller (in rows and fins and hence air pressure drop) coil to be used. It will also increase the lift that the chiller must overcome and that will reduce the chiller performance.

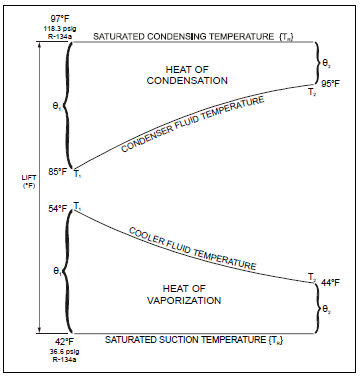

Figure 26 - Chiller Heat Exchanger Conditions

The air pressure drop savings for small changes (2 to 4oF) in the approach do not generally save enough in fan work to offset the chiller penalty. This is particularly true for VAV where the pressure drops inside an air handling unit follow the fan affinity laws. The power required to overcome the coil pressure drop decrease by the cube root as the air volume decreases. A 20% decrease in airflow results in a 36% decrease in internal air pressure drop and a 49% drop in bhp.

It is sometimes suggested that the chilled water supply temperature be 2oF colder than the supply water temperature used to select the cooling coils to make sure the "correct" water temperature is delivered to the coils. This is not recommended. For a 10oF chilled water temperature range, a 2oF temperature increase implies 20% of the chiller capacity has been lost to heat gain in the piping system! The coil would have to be selected with only an 8o

Chilled Water Temperature Range

Increasing the chilled water temperature range reduces the required flow rate and consequently the pump and piping sizes. In some situations, the savings both in capital cost and operating cost can be very large. Increasing the chilled water temperature range while maintaining the same supply water temperature actually improves the chiller performance because the chiller log mean temperature difference increases. It has just the opposite effect on the cooling coil where the LMTD decreases between the air and the chilled water. In some cases, it may be necessary to lower the supply water temperature to balance the chiller LMTD with the coil LMTD.

Table 3 - Suggested Supply Water Temperatures

| Chilled Water Temperature Ranges (oF) |

Suggested Supply Water Temperature (oF) |

| 10 | 44 |

| 12 | 44 |

| 14 | 42 |

| 16 | 42 |

| 18 | 40 |

Table 3 provides suggested supply water temperatures for various ranges. The best balance of supply water temperature and range can only be found through annual energy analysis. Every project is unique. The McQuay Energy Analyzer™ can be used to quickly evaluate the pump savings vs. chiller penalty.

☺Tip: Pump operating savings come from increasing the

chilled water temperature range, not from lowering the supply

water temperature.

Products such as fan coils and unit ventilators have standardized coils designed to work with 10 to 12oF chilled water range. When these products are used with this range of chilled water, they provide the sensible heat ratio and return water temperature generally required. When the range is increased, the coils may not provide the necessary sensible heat ratio and return water temperature. It is recommended that for these products, the chilled water range stay close to industry standard conditions. Chilled water coils are designed for the application-specific conditions so this is generally not an issue.

Condenser Water Temperature Range

Increasing the condenser water temperature range reduces the condenser water flow, which requires smaller pumps and piping. It also increases the required condenser pressure while improving the LMTD for the cooling tower. Increasing the condensing pressure on the chiller will result in a combination of increased chiller cost and reduced performance. Improving the cooling tower LMTD allows a smaller tower to be used, but the savings from this strategy will not generally offset the increased cost of the chiller.

In most cases, the overall design power requirement will go up. At full load conditions, the increased chiller power requirement to overcome the increased lift will more than offset the savings from the smaller cooling tower fan and condenser pump. This will depend on the head requirement of the condenser pump.

As the chilled water load decreases, the chiller and cooling tower work will reduce but the condenser pump work will remain the same. At some part load operating point, the savings from the smaller condenser pump will offset the chiller penalty and for all operating points below this, the increased condenser range will save energy. Whether an increased condenser temperature range will save energy annually will depend on when the crossover point occurs (the pump motor size) and the chiller operating profile (whether the operating hours favor the chiller or the pump). This can only be found with annual energy analysis.

Temperature Range Trends

Changing the temperature ranges and supply temperatures requires careful analysis. The following are some points to consider:

| □ | The traditional ARI operating conditions work very well for many buildings. |

| □ | Unnecessary reduction of the chilled water supply temperature should be avoided as it increases chiller work. |

| □ | When using standard products such as fancoils and unit ventilators, maintain the chilled water temperature range between 10 and 12oF where they are designed to operate. |

| □ | Increasing the chilled water temperature range is a good way to reduce the capital and operating cost of a building, particularly if the pump head is large or the piping runs long. |

| □ | With larger chilled water temperature ranges it may be necessary to lower the supply water temperature to find a balance between coil and fan performance vs. chiller performance. Annual energy analysis using the McQuay Energy Analyzer™ is recommended. |

| □ | If the chilled water supply temperature is reduced, consider oversizing the cooling tower to reduce the condenser water temperature and minimize the affect on the chiller. |

| □ | Always take into account the actual design ambient drybulb or wetbulb conditions when designing a chiller plant. If the location is arid, then lower the wetbulb design as per ASHRAE design weather data and select both the cooling tower and chiller accordingly. |

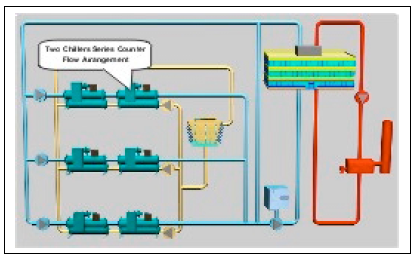

| □ | For very large chilled water ranges, use series chillers possibly with series counterflow condenser circuits to optimize chiller performance. |

| □ | Increasing the condenser water range should only be considered for projects where the piping runs are long and the pump work high. When it is required, optimize the flow to the actual pipe size that is selected and select the chillers accordingly. Consider oversizing the cooling towers to minimize the affect on the chiller. |

| □ | Use the McQuay Energy Analyzer™ to evaluate various temperature range supply water temperature combinations. Design condition performance is not an accurate indicator of the annual energy usage. |

Air and Evaporatively Cooled Chillers

The choice of chiller type and chiller plant design are inherently linked. Different chiller types have different strengths and by careful selection of chiller plant design, these strengths can be optimized. Most large plants consist of centrifugal water cooled chillers. Hybrid plants (discussed in Hybrid Plants, page 66) may also include absorption chillers.

Air-Cooled Chillers

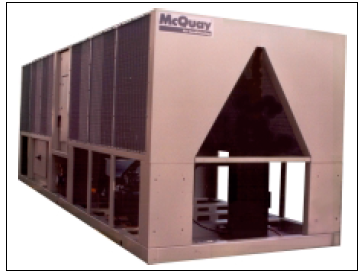

Figure 27 - McQuay Air-Cooled Screw Chiller

Many small to medium chiller plants use air cooled chillers with air-cooled screw chillers being common in the 150 to 400- ton range. Air-cooled screw chillers offer very good performance particularly at part load. The compressors are modulating rather than stepped which provides more accurate control.

Air cooled chillers avoid the need for cooling towers, condenser pumps and condenser piping which can offer substantial capital savings. Air cooled chillers do not require mechanical room space which offers additional savings.

☺Tip: Air cooled chillers do not require mechanical room space.

To estimate the savings use$50/ft2.

Another advantage of aircooled chillers is they do not consume water like watercooled chillers. A 400-ton chiller will consume over 700 gallons per hour to offset cooling tower makeup. Where water is scarce, this can be a significant cost. In addition, condenser water treatment is avoided.

Drybulb Relief

important to make an apples-to-apples comparison. Aircooled

chillers are rated with the condenser fans included. To

be fair, water-cooled chillers should have the condenser pump

and the cooling tower fans added. For instance, a watercooled

chiller with 0.55 kW/ton performance changes to 0.64

kW/ton when the condenser pumps and tower fan motor are

Air-cooled chillers have lower performance (consume more power) than water or evaporatively cooled chillers because of the increased lift. Refrigeration work is proportional to lift; doubling the lift will approximately double the work required. (For this purpose, consider lift to be the difference between chilled water supply and either cooling tower supply or ambient air drybulb) Since aircooled chillers must raise the refrigerant temperature above ambient drybulb, they consume more power.

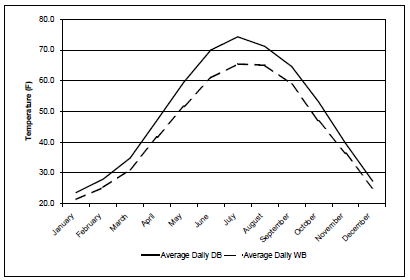

Both chiller types will improve chiller performance when the lift is reduced. This is often referred to as condenser relief. Figure 28 shows the annual drybulb vs. wetbulb temperature for Chicago. The curves show the amount of available condenser relief for each type of chiller. As expected, the wetbulb based (water-cooled) chillers offer the best performance at design conditions, however, the relief during spring and fall seasons quickly reduces the difference. In the winter, there is no advantage, as either system will operate at the minimum condensing temperature permissible by the refrigeration system.

Understanding the overall annual performance is important when considering the building use. For example, schools are rarely operating at design conditions during the summer months due to reduced occupancy. This has the effect of limiting the advantage water-cooled chillers have over air- cooled chillers.

Figure 28 - Annual Ambient Drybulb Vs. Wetbulb

Water-cooled chiller systems usually out perform air cooled chiller systems. However, when considering life cycle analysis, the payback for water-cooled systems can be very long.

Winter Operation

In climates where freezing conditions exist, winter operation must be considered. There are two issues to deal with. The first is the necessary changes to the chiller to operate in cold temperatures. All chillers have a minimum condensing temperature. Going beyond that temperature may damage the chiller. To protect the chiller, the condensing fans are staged off, or slowed down to maintain the correct condensing temperature. In very cold climates, a flooded system may be required. There are other changes that are required as well, such as larger crankcase heaters. Consult your sales representative to discuss these requirements.

The second issue is protecting the chilled water from freezing. Here are some possible solutions:

| □ | Heat trace the piping and evaporator. This is a good solution where freezing weather occurs but is not extensive. It is also a good backup for systems that are to be drained in the winter. Many chillers already include evaporator tracing. Check with your sales representative. |

| □ | Add antifreeze. A common solution is to add either propylene or ethylene glycol to the chilled water. While this will resolve the freezing issue, it will increase pumping work and de-rate both the chiller and chilled water coils. Maintaining the correct level of antifreeze in the system becomes an additional maintenance issue. A loss of antifreeze in the system due to flushing or a leak and subsequent water make-up can allow the chilled water loop to become vulnerable to freezing. Adding glycol to a system that was not designed to have it must be carefully examined to ensure the system will operate properly. |

| □ | Relocate the evaporator barrel inside the building envelope. Relocating the evaporator avoids antifreeze but will require field refrigerant piping. There are also limitations on piping distances and elevation changes. Consult your sales representative to discuss the details. |

| □ | Use an indoor chiller with a remote air-cooled condenser. This arrangement will require mechanical room space, however, the equipment can be serviced from within the building. This is a very good solution for very cold climates. The compressors are indoors and flooded condensers can easily be added. |

Air-Cooled Chiller System Design

Air-cooled chillers will affect the system selection and design details. In most cases, air-cooled chillers are limited in evaporator shell arrangements when compared to centrifugal chillers. They are designed to work well around the ARI 550/560 design conditions (54oF EWT, 44oF EWT). The design temperature range should stay within 20% of these operating conditions. Series chiller arrangements will typically double the flow and half the temperature change in the evaporator. This can lead to very high water pressure drops. Contact your sales representative to review the acceptable performance ranges of the various chiller options.

Air-cooled chillers can be used in any chiller system design. They are commonly used in single, parallel and primary/secondary systems. They can be mixed with water cooled chillers in multiple chiller applications.

Most air-cooled chillers can be used in either constant or variable flow applications. Variable flow in the evaporator is a function of the staging and chiller controller. Check with your sales representative when designing variable primary flow systems.

There are many applications that require a small amount of chilled water during the winter. For example, a hospital might require chilled water to cool an MRI year-round while the AHUs can switch to air-side economizers in the winter. When there is a requirement for small amounts of chilled water in winter, an air-cooled chiller is an excellent solution. An air-cooled chiller avoids the need to operate a cooling tower in cold (freezing) weather. In addition, the air-cooled chiller will offer equal performance to a water-cooled chiller at low ambient conditions.

Evaporatively Cooled Chillers

climates, should be considered wherever water-cooled chillers

make sense.

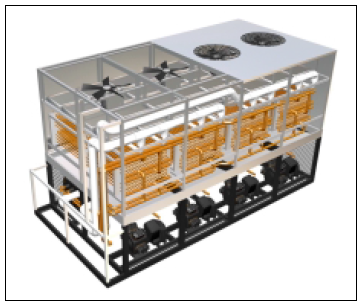

Evaporatively-cooled chillers are essentially water-cooled chillers in a box. The hot gaseous refrigerant is condensed by water flowing over the condenser tubes and evaporating. This ties the condensing temperature to ambient wetbulb like a water-cooled chiller. The condenser, water sump and pump, etc., are all integral to the chiller. Whereas a watercooled chiller will require a cooling tower, condenser pump and field erected piping, the evaporatively-cooled chilled comes as a complete package from the factory. Evaporatively-cooled chillers offer the ease and savings of air-cooled chiller installation while providing performance comparable to water-cooled chillers. Evaporatively-cooled chillers will require makeup water, water treatment and drains.

Figure 29 - McQuay EGR Evaporatively Cooled Chiller

Evaporatively-cooled chillers are often associated with hot, dry climates such as the American Southwest. However, they should be considered wherever watercooled chillers make sense.

Evaporatively Cooled Chiller System Design

Evaporatively-cooled chillers can be used in any system design. They have similar limitations as air-cooled chillers (Refer to Air-Cooled Chiller System Design, page 29).

Dual Compressor and VFD Chillers

The unique performance of both McQuay dual compressor and variable frequency drive chillers affect the chiller plant design. While it is satisfactory to simply switch conventional chillers with either dual or VFD chillers in the chiller plant, to take full advantage of these chillers capabilities, the design should be modified.

Dual Compressor Chillers

Figure 30 - McQuay Dual Compressor Chiller

McQuay dual compressor centrifugal chillers offer many advantages over conventional chillers. From a performance point of view, the chiller is most efficient at 50% capacity. At this point, only one compressor is operating and the evaporator and condenser are twice the size normally used for the compressor size. Whereas a conventional chiller NPLV can be 0.479 kW/ton, a dual NPLV is 0.435 kW/ton. An advantage a dual compressor chiller offers over a VFD chiller is it does not require significant condenser water temperature relief to provide the savings. Dual chillers can also have VFD offering the best of both worlds with an NPLV of 0.360 kW/ton or lower

The built-in redundancy of a dual compressor chiller allows the designer to use fewer chillers and still provide the owner with backup equipment. This can save considerable capital expense in installation costs.

VFD Chillers

Figure 31 - VFD Chiller

VFD chillers use a combination of VFDs and inlet guide vanes to modulate the capacity of the chiller. The VFD is used to change the speed of the compressor. For information on how this works, refer to McQuay AG 31-002, Centrifugal Chiller Fundamentals. The performance savings are obtained when the VFD is used rather than the inlet guide vanes. Typical VFD chiller NPLV is about 0.386 kW/ton. The VFD can only be used when the lift on the compressor is reduced. The lift is reduced either when the chiller load is decreased or when the condenser water temperature is lowered and/or the chilled water temperature is raised. When the lift is reduced and the VFD can be used, the chiller will operate much more efficiently at part load than a conventional chiller does.

The best way to take advantage of a VFD chiller is to reduce the condenser water temperature as much as possible. Climates with reasonable annual changes in wetbulb are prime candidates for VFD chillers.

System Design Changes

Conventional Application

Both dual compressor and VFD chillers operate much more efficiently at part load. Conventional chillers operate most efficiently at or near full load. To fully optimize a dual or VFD chiller, the design should take advantage of their part load performance.

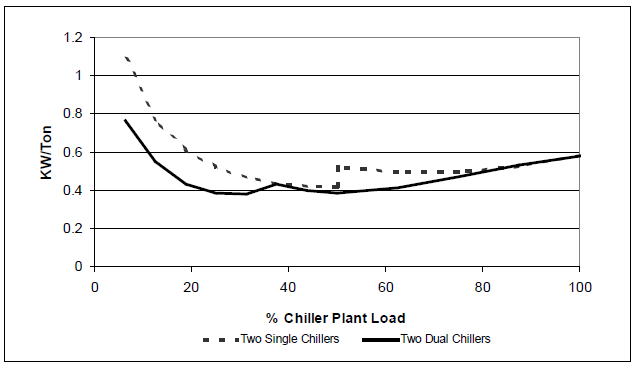

Figure 32 - Chiller Performance Vs. Plant Load

Figure 32 is based on two equally sized chillers in a primary/secondary arrangement using the ARI condenser relief profile for the entire plant. At the 50% load point, the second chiller must be started. For conventional chillers, the chiller performance drops because the load is split evenly between the two chillers and they unload to a less efficient operating point. The dual and VFD chillers actually improve their performance because the chillers are unloaded and there is condenser relief available.

Considering that most buildings experience a significant number of operating hours around 50% plant load, the dual or VFD chillers may offer appreciable savings even when used in a convention manner.

Lead Chiller Application

The first chiller that is activated in a plant, typically called the lead chiller, operates with many hours at reduced load and condenser water temperature. An example is a multi-chiller primary /secondary plant. The lead chiller sees optimal conditions for either a VFD or a dual compressor chiller. The other chillers in the plant can be conventional chillers. Each chiller that is started as the plant load increases will operate at a higher percent load with less condenser water relief and therefore will offer fewer savings.

Winter Load Application

Another good application for a dual or VFD chiller is winter load applications. Building using fancoils have considerable chiller plant loads even in winter. Other buildings such as hospitals or office buildings with computer, telecommunications or other winter chilled water loads can also take advantage of a dual or VFD chiller. In many cases, these winter loads are relatively small. Conventional thinking would require a smaller chiller sized specifically for the load. With a dual or VFD chiller, there may not be a performance penalty to use a larger chiller sized for summer loads to handle the small winter load. The peripheral loads such as pumps should be checked when evaluating performance.

A common method for sizing chillers used in series is to select both chillers to be able to perform as the lead chiller (See Series Chillers, page 44). The causes the lag chiller to be sub-optimized because the lift is reduced in the lag position. By using a VFD chiller as the upstream chiller, the VFD can take advantage of the reduced lift when operating as the lag chiller. In addition, the same chiller can be used as the lead chiller during light loads when there should be condenser water relief available.

Asymmetrical Chiller Application

Selecting the chillers to be different sizes can improve chiller plant performance based on the building load profile (see Varying Chiller Sizes, page 57). Using either a dual or VFD chiller for that larger chiller can enhance the savings. Consider a 1200-ton plant consisting of an 800-ton dual compressor and a 400-ton single compressor chiller. The dual compressor chiller can accommodate the plant load up to 800 tons. Above that, the second chiller must be started and both chillers will initially operate at 67%. The larger chiller will be more efficient when unloaded.

Low Delta T Application

Most variable flow chiller plants will see a drop in return water temperature as the load drops. The low delta T can cause serious operation issues with the plant ( See Low Delta T Syndrome, page 80). One solution is to use either dual or VFD chillers and operate two chillers at part load as opposed to one chiller fully loaded. The dual or VFD chillers partly loaded should be more efficient than one conventional chiller fully loaded. The chiller savings can be used to offset the additional pumping cost from operating peripheral pumps. Moreover, this arrangement will provide the necessary chilled water flow on the primary side to offset the low delta T problem.

Total System Analysis

When estimating the savings, consider both the type of chillers used and the available lift reduction (condenser relief) and peripheral equipment that must be operated. Many combinations of plant design can be quickly modeled using the McQuay Energy Analyzer™.

Mechanical Room Safety

Chillers represent large, powerful machines filled with refrigerants. When chillers are placed in confined spaces, care must be exercised to provide safety to the equipment operator and the public at large.

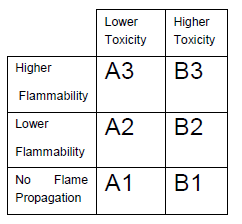

Figure 33 - ASHRAE STD 15-2001

ASHRAE Standard 15-2001, Safety Standard for Refrigeration Systems and ASHRAE Standard 34- 2001, Designation and Safety Classification of Refrigerants, provides the designer with excellent sources when designing a chiller mechanical room. In Canada, CSA –B52, provides similar information.

The following is a brief summary of the safety requirements covered by these documents as they apply to chiller mechanical rooms. This section is by no means a complete review of all requirements covered by these standards. It is recommended that the design have access to these documents. ASHRAE plans to publish a users manual for Standard 15, which may also be very helpful.

Standard 34

Standard 34 lists refrigerants and provides a safety classification as shown in Figure 34. Refer to Standard 34 or to McQuay Application Guide AG 31-007, Refrigerants for further information on common refrigerants and their safety properties.

Figure 34 - ASHRAE STD 34 Safety Classification5

Standard 15

The purpose of Standard 15 is to specify "safe design, construction, installation, and operation of refrigeration systems6." The following is a brief outline of the issues that affect chiller mechanical room design. The Section numbers refer to ASHRAE Standard 15 sections.

5 ASHRAE, 2001. ANSI/ASHRAE Standard 34-2001,Designation and Safety Classification of Refrigerants. Atlanta, Ga.: ASHRAE

6 ASHRAE, 2001. ANSI/ASHRAE Standard 15-2001,Safety Standard for Refrigeration Systems. Atlanta, Ga.: ASHRAE

Occupancy Classification

(Section 4)

Standard 15 identifies seven occupancy types (4.1.1 to 4.1.7) that consider the ability of the occupants to respond to a potential exposure to refrigerant. An example is Institutional Occupancy where it is anticipated that the occupants may be disabled and not capable of readily leaving the building without assistance. A hospital is an institutional building.

Refrigeration System Classification (Section 5)

Section 5 describes various types of refrigeration systems based on how they extract or deliver heat. Chiller plants are considered indirect systems because they cool chilled water, which in turn cools the air. Indirect systems are subsequently subdivided by how the secondary fluid (chilled water) contacts the air stream. Assuming coils are used, the classification is indirect closed system (5.1.2.3). If open spray coil systems are used then the classification becomes either indirect open spray system (5.1.2.1) or double indirect spray system (5.1.2.2).

The refrigeration system classification is used to determine the probability that a refrigeration leak would enter the occupied space. Indirect closed systems such as chiller plants are generally considered Low-Probability systems (5.2.2) providing they are either outside the building or in a mechanical room.

Refrigeration Safety Classification (Section 6)

Standard 15 uses the safety classifications listed in Standard 34. Table 4 of this Guide is based on Table 1 in Standard 15. It shows the group, refrigerant name, formula and the minimum quantity of refrigerant allowed in an occupied area. Blends such as R-407C and R-410a are classified based on the worst case fractionation of the refrigerant.

Table 4 - STD 15 Refrigerants and Amounts7

| Refrigerant Number |

Chemical Name | Chemical Formula |

Quantity of Refrigerant per Occupied Space | ||||||||||||||||||||||||||||||||||||||||||||||

| Lb./1000 ft3 | PPM (Volume) | ||||||||||||||||||||||||||||||||||||||||||||||||

| Group A1 | |||||||||||||||||||||||||||||||||||||||||||||||||

| R-11 | Trichlorofluoromethane | CCl3F | 1.6 | 4,000 | |||||||||||||||||||||||||||||||||||||||||||||

| R-12 | Dichlorodifluoromethane | CCl2F2 | 12 | 40,000 | |||||||||||||||||||||||||||||||||||||||||||||

| R-22 | Chlorodifluoromethane | CHClF2 | 9.4 | 42,000 | |||||||||||||||||||||||||||||||||||||||||||||

| R-134a | 1,1,1,2-Tetrafluoroethane | CH2FCF3 | 16 | 60,000 | |||||||||||||||||||||||||||||||||||||||||||||

| Group B1 | |||||||||||||||||||||||||||||||||||||||||||||||||

| R-123 | 2,2-Dichloro-1,1,1- Trifluoroethane |

CHCl2CF3 | 0.40 | 1,000 | |||||||||||||||||||||||||||||||||||||||||||||

Restrictions on Refrigeration Use (Section 7)

Section 7 describes the restrictions on where refrigerants can be used. It is based on results of Sections 4, 5 and 6. With high probability systems (the refrigerant can enter the occupied space i.e. a spot cooler) the maximum refrigerant level is defined in Table 1 of Standard 15 (7.2). For example R-123 can only have a concentration of 0.4 lb per 1000 ft3 occupied space. Once these levels are exceeded, the refrigeration equipment must be either outdoors or in a mechanical room (7.4). Refrigerant levels involved in chiller plants necessitate mechanical rooms or outdoor equipment.

An interesting issue occurs when an air handling unit that serves occupied spaces is in the chiller mechanical room. If a leak occurs, the refrigerant may be drawn into the air handling unit and circulated through the building. The best solution to this is to avoid air handling units in the chiller mechanical room. This may not be possible in existing buildings. Standard 15 does allow AHUs in the chiller mechanical room if they are sealed (8.11.7).

7 ASHRAE, 2001. ANSI/ASHRAE Standard 15-2001,Safety Standard for Refrigeration Systems. Atlanta, Ga.: ASHRAE

Installation Restrictions (Section 8)

Section 8 describes the installation requirements. It has general requirements (8.1 through 8.10) and then requirements for nonflammable (type A1 and B1) refrigerants (8.11). Flammable refrigerants are covered in 8.12 through 8.14. With the exception of ammonia, most common commercial air conditioning refrigerants are either A1 or B1 type. It is important to confirm this, however.

The following is a summary of section 8:

| □ | Foundations for refrigeration equipment shall be non-combustible and capable of supporting the weight (8.1). | |

| □ | Provide guards for moving machinery (8.2). | |

| □ | There should be safe access to the equipment for service (8.3). | |

| □ | Water, electrical, natural gas and duct connections must meet the requirements of local authority (8.4, 8.5, 8.6 and 8.7 respectively) | |

| □ | Refrigeration components in the air stream must be able to withstand 700oF without leaking. | |

| □ | There are requirements on where refrigeration piping may be located (8.10). | |

| □ | Other equipment is not prohibited in the chiller mechanical room unless specifically mentioned. The room must be large enough to allow service and have a clear headroom of 7.25 ft. (8.11.1). | |

| □ | The mechanical room doors shall be tight fitting that open outward and be self closing if they open into the building. There must be enough doors to allow adequate escape in the event of an emergency. The mechanical room cannot have openings that will allow refrigerant to enter the occupied space in the event of leak (8.11.2). | |

| □ | Each mechanical room shall have a refrigerant leak detector. The detector shall activate an alarm and ventilation system at a value not greater than the TLV-TWA of the refrigerant. The alarms shall be audio and visual and be located in the mechanical room and at each entrance to the mechanical room. There shall be a manual reset located in the mechanical room. Absorption chillers using water as the refrigerant do not require detectors (8.11.2.1). | |

| □ | Chiller mechanical rooms shall be vented to the outdoors as follows (8.11.3 through 8.11.5): | |

| □ | Mechanical fans are required. | |

| □ | Openings for inlet air must be provided and situated to avoid recirculation. | |

| □ | Supply and exhaust air ducts shall serve no other area. | |

| □ | Discharge of exhaust air shall be in such a manner as not to cause a nuisance or danger. | |

| □ | The emergency ventilation capacity shall be calculated as follows:

☺Tip: The refrigerant charge of a chiller can be supplied

by the chiller manufacturer. A good rule of thumb is 3 lbs. per ton. Q = 100*G0.5 Where Q = the airflow rate in cubic feet per minute G = the mass of refrigerant in pounds in the largest system (i.e., the chiller), any of which is located in the chiller mechanical room. |

|

| □ | General ventilation shall be provided when occupied at a rate of 0.5 cfm/ft2 or 20 cfm/person. The general ventilation rate must be capable of maintaining a minimum 18oF temperature rise above the inlet air or a maximum space temperature of 122oF. | |

| □ | Natural ventilation is acceptable under certain circumstances such as open structures. Consult Standard 15 for information. | |

| □ | No open flames that use combustion air from the chiller mechanical room are allowed; for instance a natural draft boiler. Combustion equipment can be in the chiller mechanical room if: | |

| □ | Combustion air is drawn directly from outdoors or a refrigerant detector is used to shut down the combustion device in the event of a leak (8.11.6). | |

| □ | There shall be no airflow from the occupied space through the chiller mechanical room unless the air is ducted and sealed in such a manner as to prevent refrigerant leakage from entering the airstream. Access doors must be gasketed and tight fitting (8.11.7). | |

| □ | Access to chiller mechanical rooms shall be restricted to authorized personnel and clearly marked as restricted (8.11.8). | |

| □ | The discharge from purge systems (i.e., negative pressure centrifugal chillers) shall be governed by the same rules as pressure relief and fusible plug devices. Absorption chillers using water as the refrigerant are exempt (8.14). | |

Design and Construction of Equipment and Systems (Section 9)

Section 9 covers the design and construction of refrigeration equipment. In most cases, the chillers are factory built and the designer will not be directly involved in the equipment design. If there is field refrigerant piping involved such as in a split system, the designer will have to be familiar with this section.

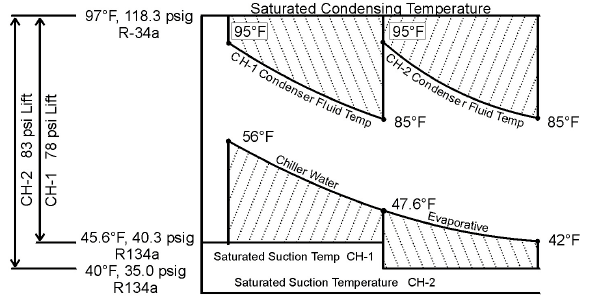

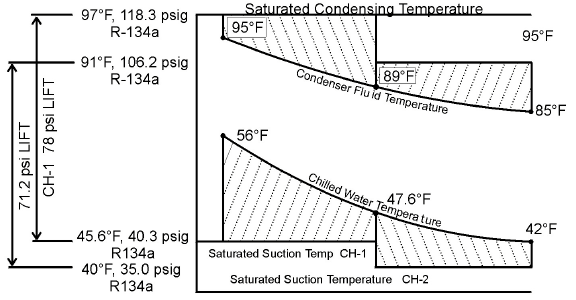

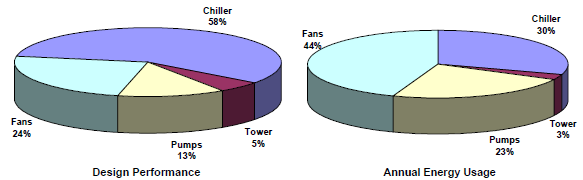

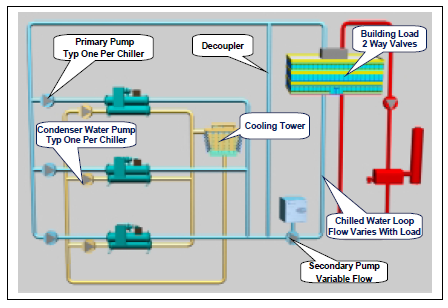

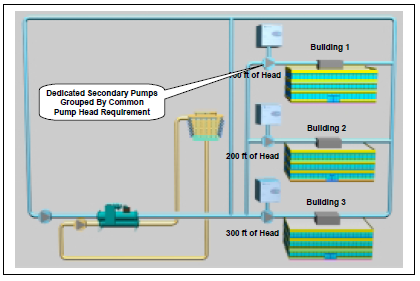

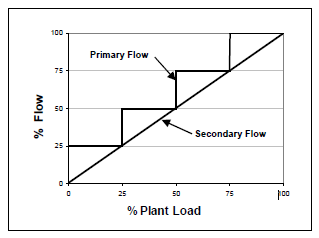

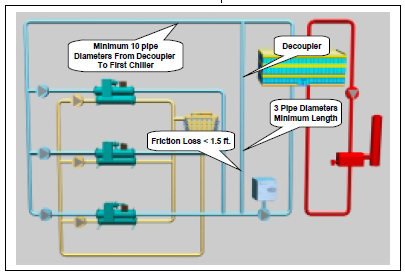

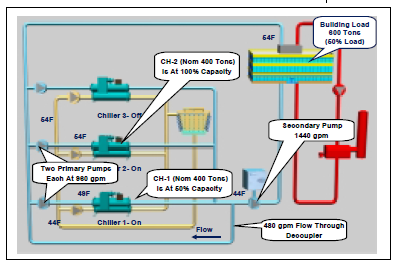

Pressure Relief Piping