Centrifugal Chiller - Fundamentals

NOTICE

The information contained within this document represents the opinions and suggestions of McQuay International. Equipment and the application of the equipment and system suggestions are offered by McQuay International as suggestions only, and McQuay International does not assume responsibility for the performance of any system as a result of these suggestions. The system engineer is responsible for system design and performance.

"McQuay" is a registered trademark of McQuay International

©1996 McQuay International

"Illustrations, information, and data cover McQuay International products at the time of publication and we reserve the right to make changes in design and construction at anytime without notice"

Introduction

There are over 80,000 centrifugal chillers in operation in North America. They are usually the most economical means to cool large buildings. Most design engineers will sooner or later use centrifugal chillers to meet their design needs.

A general understanding of their design and operating characteristics will assist in applying the product properly and avoiding major pitfalls.

The purpose of this manual is to provide design engineers with a basic knowledge of how centrifugal chillers operate so that they will better understand the interdependency of the chiller and the chilled water plant.

Basic Refrigeration Cycle

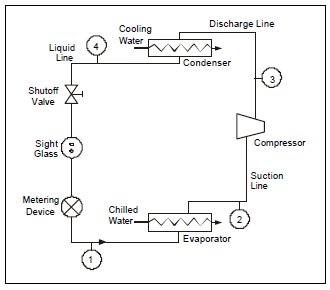

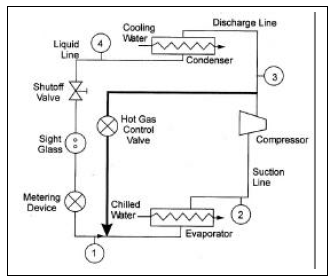

A centrifugal chiller utilizes the vapor compression cycle to chill water and reject the heat collected from the chilled water plus the heat from the compressor to a second water loop cooled by a cooling tower. Figure 1 shows the basic centrifugal refrigeration circuit. It consists of the following four main components;

Figure 1, Basic Refrigeration Cycle

Compressor

The compressor assembly is made up of a prime mover and a centrifugal compressor. McQuay Distinction™ series chillers use liquid refrigerant cooled hermetic electric motors (an industry first). The centrifugal compressor is a non-positive displacement type. It raises the pressure and temperature of the refrigerant by converting kinetic energy into pressure.

Condenser

Like the evaporator, the condenser is a heat exchanger. In this case, it removes heat from the refrigerant causing it to condense from a gas to a liquid. The heat raises the water temperature. The condenser water then carries the heat to the cooling tower where the heat is rejected to atmosphere.

Expansion Device

After the refrigerant condenses to a liquid, it passes through a pressure reducing device. This can be as simple as an orifice plate or as complicated as a electronic modulating thermal expansion valve. McQuay Distinction™ series chillers use a Thermal Expansion Valve to give excellent modulation with a wide range of capacity and temperature conditions.

Pressure-Enthalpy Diagram

The Pressure-Enthalpy (P-H) diagram is another way of looking at the refrigeration cycle. It has the advantage of graphically showing the process, the cooling effect and the work required to make it happen.

Figure 2, Refrigeration Circuit, P-H Diagram

The line from 2 to 3 represents the compression process. The work is the change in enthalpy from point 2 to point 3 times the flow of refrigerant. Simply, BTU/lb. times the lb./min equals compressor power. Compressors end up with the work of compression as heat in the refrigerant. Open drive motors reject their winding heat in to the mechanical room. Since chiller motors are typically over 95% efficient, a little less than 5% of the motor power rating ends up as heat in the mechanical room. The vertical aspect of the curve shows the rise in refrigerant pressure (and temperature) from 2 to 3.

The next process takes place in the condenser. The first section (outside the refrigerant dome) is the desuperheating process. Once the refrigerant is saturated, condensation occurs and the refrigerant changes from a gas to a liquid. Like the evaporator, the line is horizontal indicating constant pressure (or temperature). Notice the liquid subcooling portion of the condenser to the left of the dome. It is easy to see on the P-H diagram, how subcooling improves the total cooling effect. It lengthens the refrigerant effect per pound of refrigerant (a larger ΔH) so that more cooling is done without an increase in power input.

The Final process is the expansion device. This shows as vertical line from point 4 to point 1, indicating the pressure (and temperature) drop that occurs as the refrigerant passes through the TX valve.

Typical Operating Conditions

The design conditions imposed by most water-cooled HVAC systems work very well for centrifugal chillers. The Air-Conditioning and Refrigeration Institute (ARI) provides test standards and certification for a wide range of HVAC products including centrifugal chillers. The ARI standard 550/590-98 is used to test and rate chillers. Additionally, chillers typically have a certification that provides engineers and owners with a third party validation that the chiller will meet the performance the manufacturer indicates. The ARI test criteria allows an "apples to apples" comparison of different chillers.

The standard ARI rating condition is:

- Leaving chilled water temperature 44oF

- Chilled water flow rate 2.4 gpm/ton

- Entering condenser water temperature 85oF

- Condenser water flow rate 3.0 gpm/ton

- 0.0001 evaporator fouling factor and 0.00025 condenser fouling factor

The temperature change in the fluid for either the condenser or the evaporator can be described using the following formula ;

Q = W × C × ΔTF (1)

Where

- Q = Quantity of heat exchanged (btu/hr or kw)

- W= flow rate of fluid (USgpm or l/s)

- C= specific heat of fluid (btu/lboF or kJ/(kgoC))

- ΔTF= temperature change of fluid (oF oroC)

Assuming the fluid is water, the formula takes the more common form of ;

Load (btu/hr) = Flow(USgpm) × (oFin - oFout) × 500 (2)

Or

Load (tons = Flow(USgpm) × (oFin - oFout) / 24 (3)

Using this equation and the ARI design conditions, the temperature change in the evaporator is found to be 10oF. The water temperature entering the evaporator is then 54oF.

Recall that the heat that needs to be removed from the condenser is equal to the heat collected in the evaporator plus the work of compression. Assuming the work of compression is 25% of the heat collected in the evaporator, then the heat rejected in the condenser will be 125% of the evaporator heat.

Using the above equation and the ARI design conditions, the temperature change in the condenser for modern high efficiency chillers is found to be 9.4oF at 3 gpm/ton. The water temperature leaving the evaporator is then 94.4oF. This is often incorrectly rounded off to a 10 degree delta T and a 95.0oF leaving water temperature.

The ARI design conditions are frequently used as design conditions. Although they represent good "average" conditions to use, they may not represent the best design conditions to use for every project.

Figure 3, Heat Exchanger Performance

The pressure in either the evaporator or condenser will be the saturation pressure for the given temperature. These can be found on temperature-pressure charts. For HFC-134a, the condenser pressure at 97oF is 118.3 psig. The evaporator pressure at 42oF is 36.6 psig.

The rate at which the heat moves from one fluid to the other can described by equation 4 and 5.

Q = U × A LMTD (4)

And

LMTD= ΔTF/ Loge (θ1/(θ2) (5)

Where:

- Q = Quantity of heat exchanged (BTU/hr or kW)

- U = overall heat transfer coefficient (BTU/(hr × ft2 × oF))

- A = area of heat exchanger tubes (ft2)

- LMTD = Log Mean Temperature Difference between the fluid and the refrigerant (oF oroC)

- ΔTF = Temperature change of fluid (oF oroC)

- θ1 = Entering temperature difference (oF oroC)

- θ2 = Leaving temperature difference (oF or oC)

Some important relationships can be gleaned from reviewing these equations. Adding tubes (increasing surface area A) will improve heat transfer. It also lowers the fluid pressure drop. The downside to adding tubes is it adds cost.

Increasing the heat transfer coefficient U improves heat transfer. Most chillers utilize copper for tubing. Using thicker wall tubing, while more robust, will hurt performance by lowering the U value. Changing to a material with poorer heat transfer properties in the condenser will also hurt performance. The heat transfer coefficient can be improved by going to internally rifled tubing. The rifling adds surface area and increases turbulence to improve overall heat transfer. Enhancing the outside surface of the tube provides nucleation sites to improve boiling. These are parameters that the chiller manufacturer controls in the design of the chiller.

Decisions made by the chiller manufacturer or the design engineer can affect the Log Mean Temperature Difference (LMTD). Changing the saturated suction temperature or the saturated condensing temperature will change θ1 and θ2. If the saturated suction temperature is lowered from 42oF to 40oF, the LMTD will increase. It would then be possible to remove tubes (reducing the tube area A) from the chiller and still maintain the original heat transfer. The evaporator will cost less. However, the new saturated pressure is lowered to 35 psig. The compressor lift is increased from 81.7 psig to 83.3 psig. The compressor will have to work harder to do the job.

The design engineer's choices for operating water temperatures will also affect the heat transfer. Changing the return evaporator water temperature from 54oF to 58oF (switching from a 10oF ΔT to a 14oF ΔT) increases ΔTF and improves the LMTD. However, changing the leaving condenser water temperature from 95oF to 100oF (switching from a 10oF ΔT to a 15oF ΔT) increases ΔTF and lowers the LMTD. The solution to offset the larger condenser penalty ΔT is more tubes (increasing the surface area) or raising the saturated condensing pressure. The later makes the compressor work harder.

Centrifugal Compressor Theory

Figure 3 shows the saturated temperatures for both the evaporator and condenser. As mentioned earlier, the saturated pressures for these temperatures are known. At typical ARI conditions, the required pressure increase or lift is 81.7 psig. The purpose of the compressor is to provide this lift.

Centrifugal compressors differ from positive displacement compressors (such as scroll, reciprocating and screw). Centrifugals are aerodynamic or turbine type. They move gas by converting kinetic energy to pressure energy. Positive displacement compressors encase a quantity of refrigerant in a decreasing volume during the compression process. They provide excellent lift characteristics. The advantage of centrifugal compressors is their high flow rates capability and good efficiency characteristics.

The simple way to understand the principle is to imagine a ball on the end of a string. One person swings the ball on the string. A second person is standing the second floor balcony. If the person swinging the ball releases ball with enough angular momentum, the ball will fly up to the person on the second floor balcony. The weight of the ball (molecular weight), the length of the string (wheel diameter) and the rotational speed (rpm) affect the angular momentum.

The key parameter to notice is how much lift the compressor makes is proportional to its tip speed. Table 1 lists properties for the common refrigerants used with centrifugal compressors. Recall that the chilled and condenser water temperatures and the approach temperatures set the required lift. This is the same for any chiller. Reviewing Table 1, the required tip speed is very close (within 4%) for any of the popular centrifugal refrigerants. The required tip speed is around 650 fps. Whether there is a small wheel spinning fast or large wheel spinning slowly, the tip speed is relatively constant regardless of refrigerant.

Table 1, Refrigerant Properties

| Refrigerant | HCFC 123 | HFC 134a | HCFC 22 |

| Condenser Press. psig @ 100oF | 6.10 | 124.1 | 195.9 |

| Evaporator Press. psig @ 40oF (Inches of Mercury Vacuum) | (18.1) | 35.0 | 68.5 |

| Net Refrigerant Effect (BTU/lb) | 66.0 | 68.0 | 73 |

| Refrigerant. Circulated lbs/min./ton | 3.08 | 3.00 | 2.78 |

| Gas Flow cfm/ton | 18.15 | 3.17 | 1.83 |

| Head (BTU/lb) | 7.73 | 8.34 | 9.0 |

| Tip Speed ft./sec. | 656 | 682 | 707 |

| Ozone Depletion Potential (ODP) | 0.02 | 0.00 | 0.05 |

The actual amount of cooling a chiller performs depends on how much refrigerant (cfm) it moves through the compressor. Table 1 shows how many cfm of refrigerant are required per ton of cooling for the popular refrigerants. HFC-134a requires about 3 cfm/ton while HCFC-123 requires about 17 cfm/ton. HFC-134a has a higher density.

A key design parameter for centrifugal compressors is the impeller inlet velocity of the refrigerant gas. It is necessary to stay below Mach 1. Typically, the inlet velocity is limited to about 0.9 Mach. Using a 1000 ton chiller as an example, compare chillers using popular centrifugal refrigerants.

Table 2, Compressor Design Parameters

| Refrigerant | HFC 134a | HCFC 22 | HCFC 123 |

| Chiller size (tons) | 1000 | 1000 | 1000 |

| Compressor Gas Flow Rate (cfm/ton) | 2.68 | 1.74 | 17.08 |

| Compressor Gas Flow Rate (cfm) | 2680 | 1,740 | 17,080 |

| Tip Speed (fps) | 653 | 678 | 629 |

| Wheel Speed (rpm) | 11,884 | 19,464 | 3550 @60hz |

| Wheel diameter (in) | 12.6 | 8 | 40.6 |

| Acoustic Velocity @ 50oF (fps) | 484 | 535 | 417 |

| Minimum. Inlet Diameter. (in) | 4.6 | 3.5 | 13.0 |

The information in Table 2 defines the geometry of the compressor. Compressors based on HCFC-123 typically use direct-coupled motors so that at 60Hz, the compressor speed is fixed at 3550 rpm. The advantage of direct-drive is that no gearbox is required, however, fine tuning of tip speed is not possible without use of a variable frequency drive (VFD). Note that to achieve the correct tip speed, the wheel diameter needs to be 40.6 inches.

Compressors based on either HFC-134a or HCFC-22 normally use a gearbox. Small compressor (5 inch diameter wheels) speeds can reach as much as 30,000 rpm. Again, the tip speed is constant around 650 fpm. It is important to note the stress on the wheel itself is proportional to the square of the tip speed not rpm. A large wheel spinning slowly will have the same stress as a small wheel spinning quickly if the tip speeds are the same.

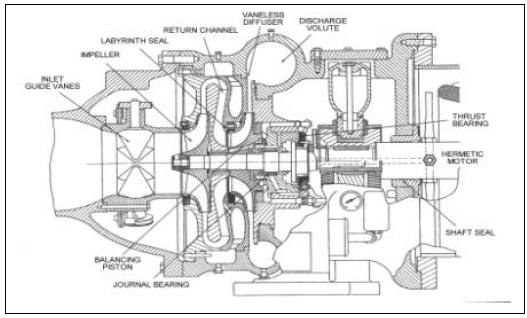

The large wheel diameters required for HCFC-123 put a design constraint on the compressor design. The wheel must be encased in a volute to collect the refrigerant as it leaves the wheel. A common solution to reduce the wheel diameter is to use two or three stage compressors. Figure 4 shows a cut away of a typical two-stage compressor. To improve compressor efficiency, refrigerant economizers are often used with two stage compressors. Figure 5 shows the P-H diagram for a two-stage compressor with economizer.

Figure 4, Two-Stage Compressor Cutaway

Above illustration Copyright 2000, American Society of Heating, Refrigeration and Air-Conditioning Engineers, Inc.,www.ashrae.org.

Reprinted by permission from ASHRAE 2000 Handbook-HVAC Systems and Equipment. All rights reserved.

Figure 5, Two-Stage Compressor P-H Diagram

Besides reducing the wheel diameter and reducing casing size, the two-stage economizer compressor has a theoretically more efficient refrigeration cycle. In this case the refrigerant goes through two expansion devices. When the refrigerant goes through the first device, some of the refrigerant flashes, or becomes a gas. The flashed refrigerant is introduced to the compressor between the two stages. It has the effect of "cooling" the superheated refrigerant gas exiting the first stage.

The balance of liquid refrigerant passes through a second expansion device and goes to the evaporator suction with lower enthalpy than if it had been flashed in one step from the condenser pressure. Consequently, there is less mass flow through the evaporator.

In practice the compressor layout limits the actual efficiency gains possible by the two stage economizer type compressors. The passageway from the first to second stage represents a significant system effect and limits the efficiency improvement. Single stage compressors like the McQuay Distinction series utilize a subcooling circuit to lower the enthalpy of liquid refrigerant and increase the cooling effect.

Compressor Surge and Stall

Figure 6 shows a typical compressor curve. Like a fan curve, the area to the left represents unstable compressor operation. Returning to the example of the ball and string, if the ball is released toward the person on the second floor balcony but stops short of reaching the person, then a stall has occurred. In reality, the refrigerant is no longer moving through the compressor and there is no cooling effect. Worse, all the shaft work is being converted into heat in the compressor that may lead to permanent damage.

Figure 6, Compressor Performance Map

A surge occurs when the ball starts to fall back to the person on the ground. In this case, the refrigerant flows backward through the compressor wheel every few seconds until the pressure builds up and the refrigerant moves forward again. This is even more dangerous than a stall because it reverses loads the thrust bearings in the compressor shaft.

McQuay Distinction™ Series chillers have SurgeGard™. SurgeGard protects the compressor from stalls and surges.

A properly selected chiller will not surge at the conditions it was designed for. A chiller can surge if the operating conditions are changed so that the lift is increased, especially at low load conditions. Raising the tower water supply temperature or lowering the chilled water supply temperature beyond design points can lead to surge.

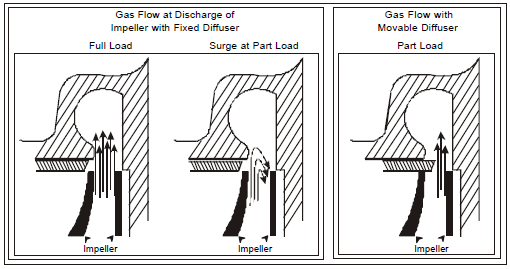

Figure 7, Compressor Movable Diffuser Geometry

Centrifugal chillers are vulnerable to surging at part load. Figure 7 shows the refrigerant gas exiting the impeller. At full capacity the gap between the impeller and the volute is sized correctly. As the chiller capacity is reduced, the refrigerant flow rate drops. The refrigerant still exits the impeller at the correct tip speed but the discharge area is too large for the reduced flow and the refrigerant stalls.

To resolve this issue, McQuay Distinction™ Series chillers use moveable discharge geometry. As the refrigerant flow rate is reduced, the discharge area is also reduced to maintain the proper velocity. Figure 6 shows the extended compressor operating range available with the moveable diffuser block. (A to A' is extended to A to A") McQuay Distinction™ Chillers will operate down to 10% capacity without surging at ARI conditions. McQuay Dual Compressor Chillers can operate down to 5%.

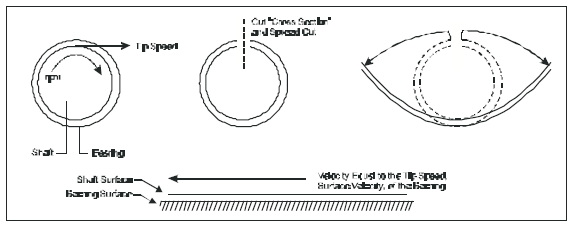

Compressor Bearings

Figure 8 shows how shaft speed (rpm) is related to bearing speed. Small, light, high speed impellers have smaller diameter shafts. The shaft tip speed is low and so is the bearing relative velocity.

Sleeve bearing systems usually have a forced (oil pump) lubrication system. The oil is heated or cooled to maintain the proper temperature range.

Figure 8, Bearing Loading

There is no shaft-to-bearing contact in a properly designed and operating sleeve bearing. The bearing life is practically infinite. The shaft rotation creates a lubricant film that the shaft then rides on. Startup is the most critical time. Light impeller/shaft assemblies have the advantage of accelerating quickly and establishing an oil film quickly.

Sleeve bearing material is typically babbit, bronze or aluminum. Bearing material must be softer than the shaft material so if foreign material enters the bearing, it embeds in the bearing and not the shaft. Since aluminum is harder than babbit, the shafts must be harder than when babbit is used.

Vessel Pass Arrangements

Figure 9, Pass Arrangements

The number of passes used is related to the water velocity in the tubes. Higher velocities improve heat transfer on the water side (inside) of the tube. Higher tube velocities reduce the LMTD and improve chiller efficiency, but unfortunately, also raise the fluid pressure drop.

To avoid laminar flow, the Reynolds number for the fluids must remain above 7500. Rather than calculating the Reynolds number, common practice is to ensure fluid velocities are maintained above 3 fps. The maximum tube velocity is limited by tube erosion. To avoid damaging the tubes, 12 fps is typically used as an upper limit.

A balance must be struck between chiller efficiency (high tube velocity) and low fluid pressure drop (low tube velocity). While every situation is unique, here are some guidelines;

Table 3, Pass Temperature Range

| No of Passes | Temperature Range (F) |

| 1 | 0-5 |

| 2 | 6-12 |

| 3 | 13-18 |

Capacity Control

The volume flow rate of the centrifugal compressor will change in response to changes in head or changes in cooling required. HVAC applications necessitate the compressor to operate over wide range of lift and cooling capacities.

Inlet Guide Vanes

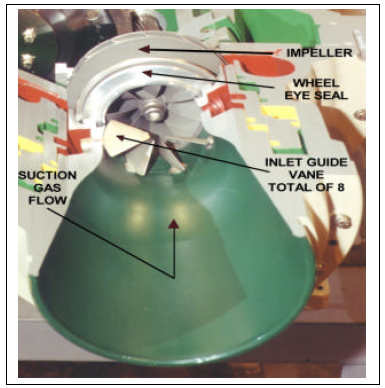

Figure 10, Compressor Inlet Guide Vanes

Varying Compressor Speed

Changing the compressor speed can also control compressor capacity. If the prime mover is a turbine or internal combustion engine, the prime mover's speed can easily be changed. Induction motors require a Variable Frequency Drive (VFD) to change their speed.

Changing the compressor speed also changes the tip speed. As the tip speed is lowered, the lift the compressor can produce is lowered. For compressor speed control to work, the required lift must be reduced either by raising the supply water temperature or lowering the condenser water temperature. The most common way to reduce the lift is to lower the condenser water temperature. As the ambient wet bulb temperature drops, it is possible to lower the condenser water temperature and realize significant savings. However, it is important to remember that unless the compressor lift is lowered, varying compressor speed cannot work.

Variable Frequency Drives

The Variable Frequency Drive (VFD) replaces the compressor motor starter. They can be unit or remote mounted. In most cases, the VFDs have to be water-cooled. Chilled watercooled units add load to the chilled water loop. Condenser water-cooled units do not affect the chilled water loop but are vulnerable to scaling from the open tower water and are not recommended.

Chillers with VFDs still have inlet guide vanes. The chiller controller monitors the operating conditions and uses a combination of inlet guide vanes and speed control. Compressor speed is typically only lowered to about 60% of the design speed. Since VFDs introduce drive losses, the chiller will not be as efficient at full load (speed) with a VFD as with a standard starter.

VFDs act as a soft starter. They can lower the inrush current for the motor to almost that of the full load running amps. This can be very important where chillers will operate on emergency power generator sets.

The power factor with a VFD is typically around 0.96, which is very good. However, the harmonics from a VFD can be of major concern. The chiller motor is typically the largest single electrical load in the building. Harmonics generated by the VFD can disrupt computer and communications equipment. Careful Harmonic analysis is required whenever a VFD chiller is applied.

With the right operating conditions, VFDs can offer significant energy savings. A careful economical analysis with realistic load profiles and ambient wet bulb is recommended when considering using VFDs.

Hot Gas Bypass

Figure 11, Hot Gas Bypass

Hot gas bypass is inefficient and should be avoided whenever possible. Careful selection of equipment size and using compressor that unload to 10 percent of full load capacity can avoid the need for hot gas bypass in most HVAC applications. Many process applications still require hot gas bypass in order to completely eliminate compressor cycling and maintain constant chilled water temperature from zero load to full load.

Prime Movers

Most chillers use either open-drive or hermetic induction motors to drive the compressors. Open drive motors are easier to service or replace but being air-cooled means the motors operate at hotter temperatures. The higher operating temperature places additional stress on the motor compared to refrigerant-cooled motors. A major disadvantage to open-drive is that the compressor must have a shaft seal that will leak refrigerant and require a high maintenance effort. Internal combustion (I.C.) engines operating on natural gas, propane and diesel are also used. Steam turbines are sometimes used on large tonnage chillers.

Internal combustion engines offer the opportunity to use a primary energy source and the waste heat from the engine can be collected and used. In such applications COPs around 2 (from a primary energy source) are possible.

For cogeneration applications where waste steam may be available, turbine driven chillers can be a good fit.

For both I.C. engine's and turbine's first cost and maintenance costs are higher than induction motors. Careful economic analysis is required to ensure these more expensive prime movers are viable.

Power Factor

Electrical energy is consumed in varying degrees of three forms:

Resistance

Inductive Resistance

Capacitive Resistance

When electrical energy is consumed in the resistance component, real work is done. Examples include lighting and resistance heating. Resistive work is measured in watts.

When electricity is applied to a pure inductor no real work is done. Examples of inductive loads are transformers and lighting ballasts. The inductive reactive power is measured in kilo-volts-amperes-reactive or kVAR.

When electricity is applied to a capacitor, no real work is done. The capacitive reactive power is measured in kVAR. Capacitive reactive power can "cancel" inductive reactive power.

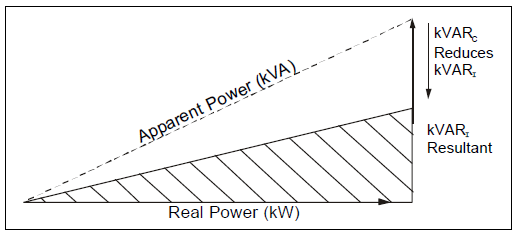

Figure 12, Power Triangle

In reality there are no pure resistance, capacitance or inductance loads. It is always a combination of the three. Figure 12 shows the power triangle and demonstrates how capacitance can "cancel" reactance. Apparent power is the vector sum of real power and reactive power and is measured in kVA.

Utilities typically bill their customers either 100% of the real power (kW) or 90% of the apparent power (kVA), whichever is larger. If the reactive portion of the power triangle is not controlled, the operating cost will go up.

Power factor (p.f.) is the ratio of actual power (kW) to apparent power (kVA). The large inductive motors associated with centrifugal chillers increase the reactive power portion of the building’s power triangle. To minimize this, capacitors are often added.

Most centrifugal motors have a power factor between 0.87 and 0.91. Additional capacitors can be added to raise the power factor to a practical limit of 0.95. Correction above 0.95 is not recommended since voltage upsets could produce a leading power factor (greater than 1.0) which can damage the motor.

The power factor decreases as the motor load is reduced. Below 50% without correction, the power factor drops very quickly. By raising the power factor to 95% at full load, the power factor will remain satisfactory over a wider operating range.

Motor Starters

Large chillers can have motors in excess of 1000 hp. The inrush current must be controlled to minimize the impact on the power grid. Several motor starter types are used for centrifugal chillers. These include Across-the-Line, Star-Delta, Autotransformer, Primary Reactor and Solid State. A detailed description of these starters is beyond the scope of this document. For more details see McQuay PM STARTER, Starters for Centrifugal Chillers -(latest edition).

Refrigerant Metering Devices

McQuay Distinction chillers use thermal expansion valves that measure and control refrigerant superheat to the compressor inlet. The valve provides the necessary pressure drop and also ensures the proper flow of refrigerant to the evaporator. As the superheat climbs indicating increasing load, more refrigerant is added. If the superheat drops, the refrigerant flow rate is lowered. This maximizes the efficiency of evaporator.

Another common metering device is an orifice plate that restricts the refrigerant flow from the high pressure side to the low pressure side of the refrigerant circuit.

Chiller Controls

Modern chiller controls are DDC based and employ PID (proportional-integral-derivative) loops for stable control. The control parameter is the supply chilled water temperature. The controller measures the supply chilled water temperature and modulates the chiller capacity to maintain the setpoint. McQuay chillers control to ± 0.2oF.

Many other parameters are measured and controlled to ensure smooth and efficient operation of the chiller. This information can be used for energy management, preventive maintenance and service diagnostics. Most manufacturers have some form of gateway to allow the chiller controlled to be connected to a Building Automation System (BAS). McQuay chillers use Protocol Selectablity™ to allow the information to be transferred on customer's choice of protocols.

Purge Systems

Chillers using either CFC-11 or HCFC-123 have evaporators that operate in a vacuum. At ARI conditions, a chiller using HCFC-123 has an evaporator pressure of 17.6 inches of Mercury. It is very difficult to create a perfectly sealed unit, so some air (including moisture) will leak into the chiller. The air is referred to as a non-condensable. Non condensables create two problems. The first is the compressor does work moving the non-condensables but they offer no refrigeration effect. They can also blanket tubes with air eliminating them from doing any heat exchange work. Non condensables lower the real efficiency of the chiller from the cataloged or rated performance by as much as 8% at 60 % load and 14% at 100 % load.

The second issue with non-condensables is they are contaminants. Moisture, in particular, is a problem. Moisture allows the formation of acids within the chiller that can cause serious damage to motor windings and bearings.

To minimize the affect of non-condensables with low pressure chillers, an additional component called a purge unit is required. The difficulty with purge units is they are another service item and also release refrigerant to the atmosphere when they remove non-condensables. Today, purge unit efficiency is very good, however older purge systems could lose as much as 25% of the chiller's refrigerant charge per year.

Chillers using positive pressure refrigerants such as HFC-134a do not require purge units. Non-condensables cannot enter the chiller to damage it or reduce it’s efficiency.

Pumpout Systems

Pumpout systems consist of a storage tank large enough to hold the chillers entire refrigerant charge and a refrigerant pump/compressor to move the refrigerant from the chiller to the pumpout tank and back again. Their primary purpose is for servicing the chiller. They allow the charge to be stored while the refrigeration circuit is worked on.

McQuay Distinction™ Series chillers do not require a separate pumpout system. The condensers are specifically designed to hold the entire refrigerant charge and the necessary valves to isolate the charge in the condenser are included.

Dual Compressor Chillers

As inlet guide vanes are used to modulate the capacity of a compressor, the compressor efficiency drops off dramatically. Where there is tower water relief (decreasing tower water temperature), variable speed drives can be used to improve part load efficiency. By utilizing two compressors on a common refrigeration circuit, it is possible to greatly improve the part load efficiency of a centrifugal chiller. This is a major benefit of a dual compressor chiller.

Dual compressor chillers have two compressors operating in parallel between a common evaporator and condenser. For example, a 1000 ton dual will have two nominal 500 ton compressors mounted. As the chiller unloads from 100% load, one compressor shuts off at approximately 600 tons (60% of full load). Only one compressor is required to circulate enough refrigerant to meet the load. That compressor is operating with its inlet guide vanes wide open and at maximum compressor efficiency. Additionally, the compressor is operating with a condenser and evaporator designed for twice the capacity. In effect, the two heat exchangers have twice the required surface area. This lowers the lift and improves the compressor performance. The need for operating only one compressor at mid-range chiller loads accounts for the superior performance of these chillers.

Dual compressor chillers have a unique performance profile. Single compressor chillers are most efficient at or near 100% capacity. Dual compressor chillers are most efficient at 50% to 60% capacity. This matches the typical building load profile very well, offering optimum efficiency where there are the most run hours.

ARI Standard 550/590-98

ARI Certification On-going performance verification of chiller capacity and power input plus ARI certified computerized selection output assure the owner of specified performance in accordance with the latest version of ARI Standard 550/590.

All chillers that fall within the scope of the certification program have an ARI certification label at no cost to the owner. Equipment covered by the ARI certification program include all water-cooled centrifugal and screw water chilling packages rated up to 2000 tons (7,000 kW) for 60 hertz service at ARI standard rating conditions, hermetic or open drive, with electric driven motor not exceeding 5000 volts, and cooling water (not glycol). For 50 hertz application the capacity range covered is 200 to 1,000 tons (700 to 3500 kW).

Published certified ratings verified through testing by ARI include:

- Capacity, tons (kW)

- Power, kW/ton (COP)

- Pressure drops, ft. of water (kPa)

- Integrated Part Load Value (IPLV) or Non-Standard Part Load Value (NPLV)

As part of the ARI certification program, ARI has the McQuay computer selection program used to select and rate chillers. The certified computer program version number and issue date for all manufacturers is listed in the ARI Directory of Certified Applied Air- Conditioning Products available on www.ari.org.

ARI Standard 550/590-98 for Centrifugal or Screw Water -Chilling Packages and associated manuals define certification and testing procedures and tolerances of all units that fall within the application rating conditions.

Leaving chilled water temperature ...........................40oF to 48oF

Entering condenser water temperature .....................60oF to 95oF

Rating outside the range of the certification program may be listed or published but must include a statement describing such. The standard rating conditions are:

Leaving chilled water temperature ...........................44oF

Evaporator waterside field fouling allowance ............0.0001

Chilled water flow rate ............................................2.4 gpm/ton

Entering condenser water temperature .....................85oF

Condenser waterside field fouling allowance.............0.00025

Condenser water flow rate .....................................3.0 gpm/ton

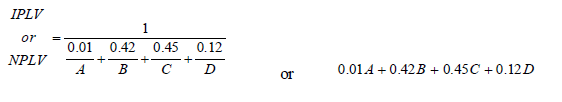

IPLV/NPLV Defined Part load performance can be presented in terms of Integrated Part Load Value (IPLV), which is based on ARI standard rating conditions (listed above), or Non-Standard Part Load Values (NPLV), which is based on specified or job site conditions. IPLV and NPLV are based on the following equation from ARI 550/590.

| Where: | A = kW/ton at 100% | Where: | A = COP at 100% |

| B = kW/ton at 75% | B = COP at 75% | ||

| C = kW/ton at 50% | C = COP at 50% | ||

| D = kW/ton at 25% | C = COP at 50% |

The percent of annual hours of operation are weighted as follows:

100% Load at 1%, 75% Load at 42%, 50% Load at 45%, 25% Load at 12%

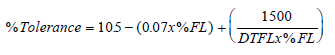

Tolerances The ARI test tolerance that accounts for instrument error, per ARI Standard 550/590-98, for capacity (tons), power input per ton (kW/ton), and heat balance is:

| Where | FL = Full Load |

| DTFL = Chilled Water Delta-T at Full Load |

Summary

Centrifugal chillers are a key building block for many HVAC systems. As the market place demands more and more performance from their HVAC systems, chillers will be applied in new and innovative ways. Variable flow and chillers with VFDs are two such applications. While this manual does not go into detail on applications, it does give the engineer the basics to understand the impact such design considerations will have on a centrifugal chiller.

Further recommended reading includes McQuay's Chiller Plant Design Application Guide AG 31-003. Your local McQuay Sales Representative can also help with specific applications, selections and further training.