VENTILATION, INFILTRATION & EXFILTRATION

Outdoor Air is assumed to be fresh, clean air made up of the right combination of oxygen (21%), nitrogen (78%), and other gases (1% hydrogen, argon, carbon dioxide, water vapor). People and all animal life need oxygen to live. Nitrogen and the other gases are inert and not harmful to animal life. People breathe in oxygen and breathe out carbon dioxide. The oxygen level in an enclosed occupied space must therefore be replenished by supplying outdoor air. The outdoor air must be cleaned and filtered before it is supplied.

Indoor Air in an enclosed occupied space loses it's oxygen due to the occupants and it can also be contaminated from within the space with organisms such as bacteria and viruses and with pollutants from the processes that occur in the space. Indoor air must therefore be cleaned and it's oxygen content maintained by adding outdoor air. For a typical office building, the outdoor air supply quantity is determined on the basis of the number of occupants and process pollution. For example, 20 cubic feet per minute (CFM) per person. In the case of industrial applications, the outdoor air quantity also depends mainly on the amount of pollutants generated in the space.

Ventilation Air can be natural or mechanical. In modern commercial buildings, the term ventilation refers to mechanical ventilation. It is the intentional controlled introduction of outdoor air into an enclosed occupied space. Ventilation is provided using mechanical systems such as fans. The entry of outdoor air through an open door or window is considered infiltration and not ventilation. The total air supplied to a space consisting of outdoor air and indoor recirculation air is not ventilation air either. It is referred to as Supply Air

Infiltration Air is the unintentional and uncontrolled entry of outdoor air into an enclosed space. Infiltration occurs through cracks in the building envelope and due to pressure differences between inside and outside. The outdoor air entering through open doors and windows is considered infiltration although the purpose of opening the door or window might be ventilation. Infiltration occurs mainly in winter when the air outside is colder and heavier than the air inside. It depends on wind velocity, wind direction and the air-tightness of the building envelope. In the case of high-rise buildings the stack effect also causes infiltration

Exfiltration Air refers to the flow of indoor air from an enclosed building space to the outdoors. Commercial air-conditioned buildings are designed to be air-tight (the windows cannot be opened) and pressurized. In summer the air inside is colder (air-conditioned) and therefore denser (heavier) than the hotter air outside. The natural air flow direction is therefore from inside to outside. Since commercial buildings are pressurized, the air flow leakage is from the inside to the outside. Exfiltration amount is small and usually neglected in HVAC calculations.

Ventilation (outdoor) Air requirements are determined using one or more of the following methods.

- CFM (cubic feet per minute) per person

- CFM per square foot (area) of the space

- Air Changes per Hour (ACH)

- Percent of total supply air

CFM per Person is used in most commercial building applications. The purpose of supplying outdoor air is to replenish the oxygen (O2) content of the indoor space which is being converted into carbon dioxide (CO2) by the occupants in the space and also to dilute pollutants generated in the space. CFM/Person for O2/CO2 control is about 5. When pollution is considered, cfm/person can vary from 5 in theaters and indoor stadiums where the occupancy density can be 10 sqft/person to 20 in offices where the occupancy density is 100 sqft/person. For example, 100 sqft of a theater space will hold 10 people and the OA supply is 5 * 10 = 50 cfm. 100 sqft of an office space has 1 person and the OA supply is 20 cfm. The lower 5 cfm/person in a theatre is therefore to save energy and it takes into account that theatres are occupied for short intervals of time.

CFM per SQFT of floor area is similar to CFM/Person since the design number of people in the space is usually based on the area of the space. CFM/SQFT is a constant quantity while the number of people in the space can be unknown or uncertain. Outdoor air quantity is sometimes calculated as the greater of both CFM/Person and CFM/SQFT.

Air Changes per Hour (ACH) method in determining outdoor air quantity is used in buildings such as hospitals. The emphasis here is on replacing the entire quantity of indoor air periodically. For example, 2 ACH of OA means that the room air is replaced twice in one hour with outdoor air. ACH method means that the quantity of OA increases with floor to ceiling height or room volume. For example: floor area = 100 ft2 and ceiling height = 10 ft. 2 ACH is 2 * 100*10 = 2000 cubic feet in 1 hour or 33.3 cubic feet per minute. If the ceiling height is raised to 20 feet then 2 ACH becomes 4000 cubic feet per hour or 66.6 CFM.

Percent of Total Supply Air is used if the other methods produce low outdoor air quantities. This is a judgment decision. For example, the outdoor air quantity should not be less than 10% of the total supply air in order to maintain the freshness of the supply air. Percent outdoor air calculated using the other methods is usually between 10% and 30%.

Infiltration Air quantities are determined using one or more of the following methods.

- CFM per lineal foot of window and door perimeter lengths

- CFM-1 per sqft of window area and CFM-2 per sqft of wall area (CFM-1 > CFM-2)

- CFM per sqft of window and wall area

- CFM per sqft of space floor area

- Space ACH (air changes per hour)

Infiltration rates vary throughout the year. It is greater in winter when the temperature difference between inside and outside is greater. For example, 75oF inside and 0oF outside in winter and 75oF inside and 95oF outside in summer. Infiltration rates depend on wind velocity and direction and also on the building envelope construction. Construction can vary from porous and leaky to air-tight and impenetrable.

When the building is pressurized (the air supply fan systems are on) summer infiltration can be neglected but there is still some infiltration in winter. The infiltration heating load is significant when the supply air systems are off during unoccupied periods. Infiltration can be a very big component of winter heating energy loads.

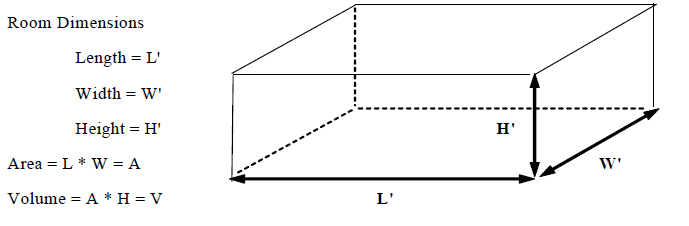

Air Changes per Hour (ACH)

1 Air Change per Hour means that the volume V of air in the room is changed or replaced once per hour. The supply air quantity is therefore V cubic feet in one hour (CFH).

6 Air Change per Hour means that the volume V of air in the room is changed or replaced six times per hour. The supply air quantity is therefore 6*V cubic feet in one hour (CFH).

N Air Change per Hour means that the volume V of air in the room is changed or replaced N times per hour. The supply air quantity is therefore N*V cubic feet in one hour (CFH).

Supply (or Exhaust) Air (CFH) = N * V Supply (or Exhaust) Air (CFM) = N * V / 60

CFM = N * V / 60 N = CFM * 60 / V

CFM = cubic feet per minute of air

V = Room volume (cubic feet or ft3)

N = Number of Air Changes per Hour

Example:

Room dimensions: L = 30' W = 20' H = 10'

Minimum supply air (SA) = 6 ACH (air changes per hour)

Calculate supply air (SA) in cubic feet per minute (CFM)

Room Volume (V) = L * W * H = 30 * 20 * 10 = 6,000 cubic feet (ft3). N = 6 ACH

CFM = N * V / 60 = 6 * 6,000 / 60 = 600.

Example:

Room dimensions: L = 30' W = 20' H = 10'

Supply air (SA) = 900 CFM

Calculate N (Number of Air Changes)

Room Volume (V) = L * W * H = 30 * 20 * 10 = 6,000 cubic feet (ft3). CFM = 900

N = CFM * 60 / V = 900 * 60 / 6,000 = 9.

Example:

Room dimensions: W = 40' L = 50'

Supply air (SA) = 4,000 CFM

Minimum Supply Air Changes per Hour (ACH) = 8

What is the maximum ceiling height (H) ?

Volume (V) = W * L * H = 40 * 50 * H = 2,000 * H. N = 8, CFM = 4,000

N = CFM * 60 / V. 8 = 4000 * 60 / (2000 * H). H = 15 feet

Example:

Room dimensions: W = 40' L = 50' H = 10'

Occupancy Criteria: 50 ft2/person (or 1 person per 50 ft2)

Ventilation Criteria: 25 cfm per person

Minimum Supply Air (SA) = 15 air changes per hour (ACH)

Determine: (1) No. of People, (2) Ventilation CFM, (3) Ventilation ACH

(4) Supply Air CFM, (5) Supply Air CFM/ft2, (6) Percent Ventilation Air

Room Area (A) = 40' * 50' = 2,000 ft2, Room Volume (V) = 2,000 ft2 * 10' = 20,000 ft3.

- No. of people = 2000 ft2 / 50 ft2per person = 40

- Ventilation CFM = 40 people * 25 cfm/person = 1000 cfm

- Ventilation ACH = 1000 cfm * 60 min/hr / 20000 ft3 = 3

- Supply Air CFM = 15 ACH * 20000 ft3 / 60 min/hr = 5000 cfm

- Supply Air CFM/ft2 = 5000 cfm / 2000 ft2 = 2.5 cfm/ft2

- Percent Ventilation Air = 1000 cfm OA / 5000 cfm SA * 100 = 20%

Typical System

| System - Plant Data | (F) | (F) | |

| Condenser Entg Wtr Temp = | 85 | Cooling Coil Lvg Air Temp = | 48.5 |

| Condenser Lvg Wtr Temp = | 100 | Temp Rise Supply Air Fan = | 2.0 |

| Cooling Coil Entg Wtr Temp = | 56 | Temp Rise Ductwork = | 0.5 |

| Cooling Coil Lvg Wtr Temp = | 40 | Space / Room Air Temp = | 75 |

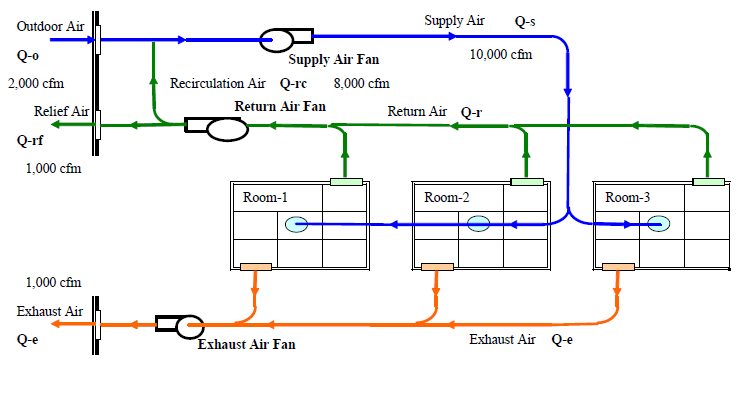

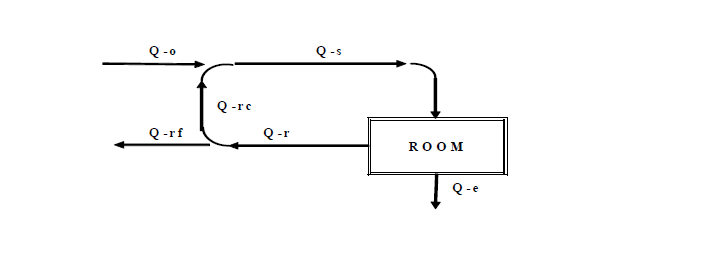

Determining Air Quantities (Q). The typical procedure sequence is to determine:

- Supply Air (Q-s)

- Outdoor Air (Q-o)

- Exhaust Air (Q-e)

- Return Air (Q-r)

- Recirculated Air (Q-rc)

- Relief Air (Q-rf)

- Transfer Air (Q-tr)

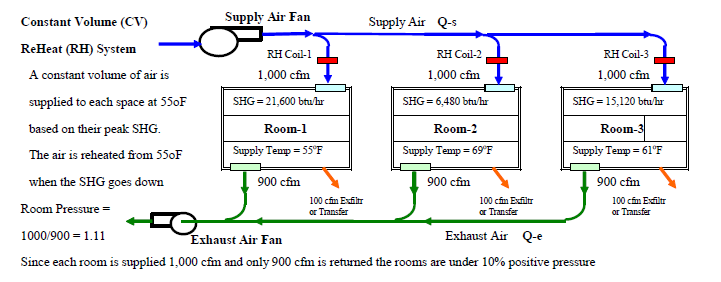

Supply Air Quantity (Q-s) is first calculated to offset sensible heat gain (SHG) in the room. This calculated quantity cannot be less than the minimum supply required by code or standard. The minimum is determined to maintain good air circulation and air changes per hour of clean air. Example: the room area is 1,000 ft2, Q-s calculated on the basis of SHG is 700 cfm and the minimum required by standard is 1.1 cfm/ft2 of room area then the supply cfm is 1,100. So the design supply is 1100 cfm and not the calculated 700 cfm. As the Room SHG drops as the climate moves from summer to winter then (a) the supply air temp must be increased or (b) the supply air quantity must be decreased.

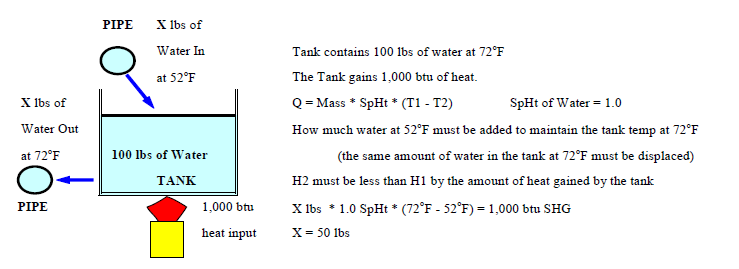

The following is an example using water where cold water must be added to a tank of water to offset the heat gained by the water in the tank.

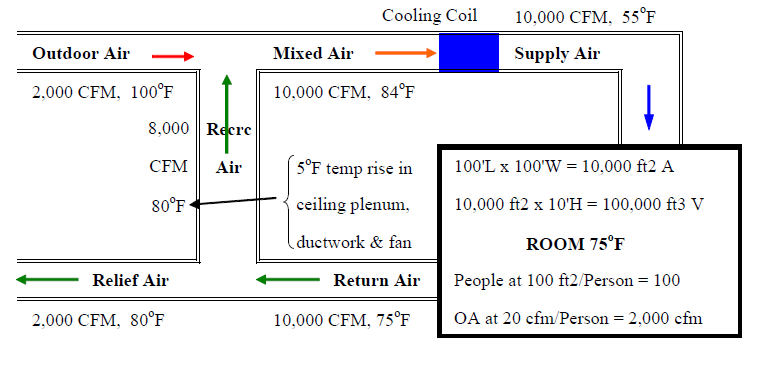

Given SHG in room = 216,000 btu/hr, how much air at 55oF should be supplied?

CFM = SHG / [ 1.08 * (Tr - Ts) ] = 216,000 / [ 1.08 (75 - 55) ] = 10,000 cfm

SHGTotal Room SHG = External SHG + Internal SHG

Heat content of supply air must be less than the room heat content by the amount of the Room SHG

Difference in heat content of supply and return air = Ms * SpHt. * ( Tr - Ts ) and this should equal SHG

SHGDifference in heat content of supply and return air = Ms * SpHt. * ( Tr - Ts ) and this should equal SHGMs = Mass (lbs/hr) of Supply Air = Q-s (ft3/min) * 0.075 (lbs/ft3) * 60 (min/hour) = Q-s * 4.5

| Q-s * 4.5 * SpHt * ( Tr - Ts ) = SHG | Specific Heat of Air (SpHt) = 0.24> |

| Q-s * 1.08 * ( Tr - Ts ) = SHG | Q-s = SHG / [ * 1.08 * ( Tr - Ts ) ] |

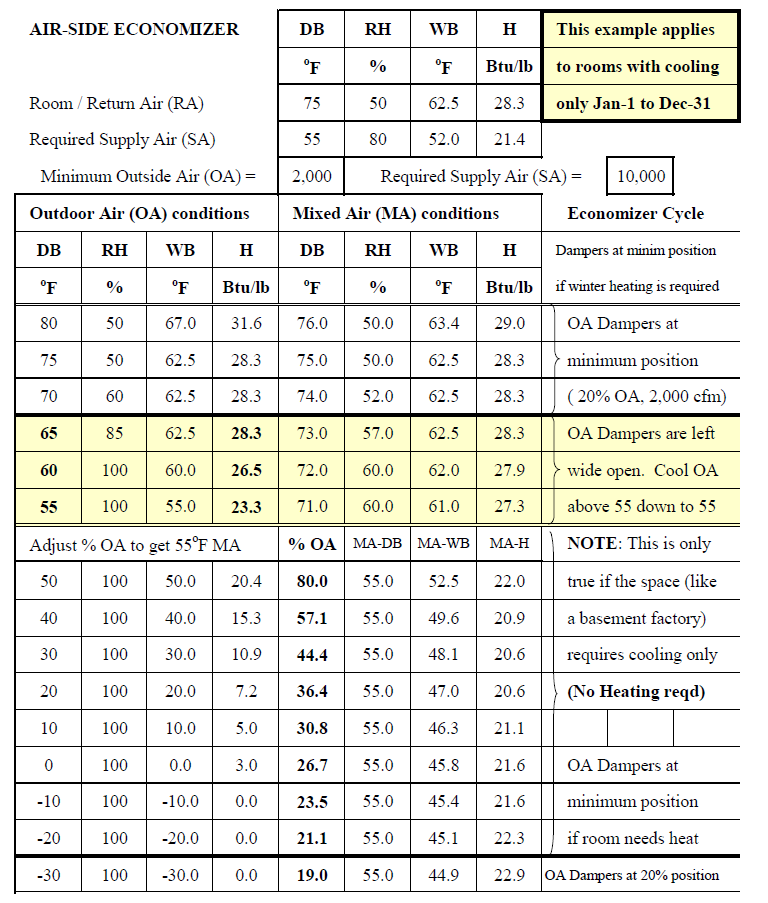

During intermediate weather (Spring & Fall), the condition of the outdoor air is between room temp of 75oF and required cooling supply air temp of 55oF. In which case it can be used directly for cooling. One type is based on DB temps and the other type is based on enthalpies. Enthalpy is theoretically better since it is the supply air heat quantity that must offset the room SHG. However, enthalpy is difficult to measure. Typically 100% OA is used when the OA temp is between 55oF and 65oF. Below 55oF the percent OA is gradually reduced from 100% to 20% and mixed with RA from 0% to 80% to get MA temp of 55oF. The table above only applies to rooms that have heat gain only. When the OA temp drops below 55oF the rooms usually require heating and so the OA dampers go back to the minimum position.

Example:

Room SHG = 216,000 btu/hr, Room Temp Tr = 75oF, Supply Temp Ts = 55oF

Q-s = SHG / [ * 1.08 * ( Tr - Ts ) ] = 216,000 / [ 1.08 * ( 75 - 55 ) ] = 10,000 cfm

Example:

Room dimensions: 150' L*100'W*10'H. Area (A) = 15,000 ft2. Volume (V) = 150,000 ft3.

Minimum supply air (SA-min) is the greater of 0.8 cfm/ft2 or 6 air changes per hour.

Q-s at 0.8 cfm/ft2 = 0.8*15,000 = 12,000 cfm. Q-s at 6 ACH = 6*150,000/60 = 15,000 cfm.

Minimum supply air (SA-min) = 15,000 cfm (15,000 > 12,000).

Room SHG = 302,400 btu/hr. The required room temperature (Ts) = 75oF.

The supply air temperature (Ts) has been selected as 55oF.

Q-s ft3/min * 60 min/hr * 0.075 ft3/lb * 0.24 btu/lb * (Tr - Ts) = SHG btu/hr

Q-s = SHG / [ 1.08 * (Tr - Ts) ] = 302,400 / ( 1.08 * (75 - 55) = 14,000 cfm.

Since SHG calculated cfm of 14,000 is less than the minimum cfm required of 15,000, the supply air quantity (Q-s) = 15,000 cfm. What would be the room temp (Tr) if 15,000 cfm was supplied at 55oF (Ts).

Q-s = SHG / [ 1.08 * (Tr - Ts) ] = 302,400 / ( 1.08 * (Tr - 55) = 15,000 cfm.

302,400 / 15,000 = 1.08 * Tr - 1.08 * 55. Tr = 73.7oF. This is less than the required 75oF.

What should the supply air temperature be if the supply air is 15,000 cfm and the cooling load is 302,400. Q-s = SHG / [ 1.08 * (Tr - Ts) ] = 302,400 / ( 1.08 * (75 - Ts) = 15,000 cfm.

302,400 / 15,000 = 1.08 * 75 - 1.08 * Ts. Ts = 56. 3oF. The supply temp has to be increased,

Example:

302,400 is peak SHG on July 21 at 3:00 PM. The SHG on June at 8:00 AM is 200,000 btu/hr.

(a) what should the supply air temp be to maintain 75oF in the room?

(b) what should the supply volume be to maintain 75oF in the room and supply temp is 55oF?

(a) Q-s = SHG / [ 1.08 * (Tr - Ts) ]. SHG = 200,000 and CFM = 15,000

15,000 = 200,000 / [ 1.08*75 - 1.08*Ts]. Ts = 62.7oF.

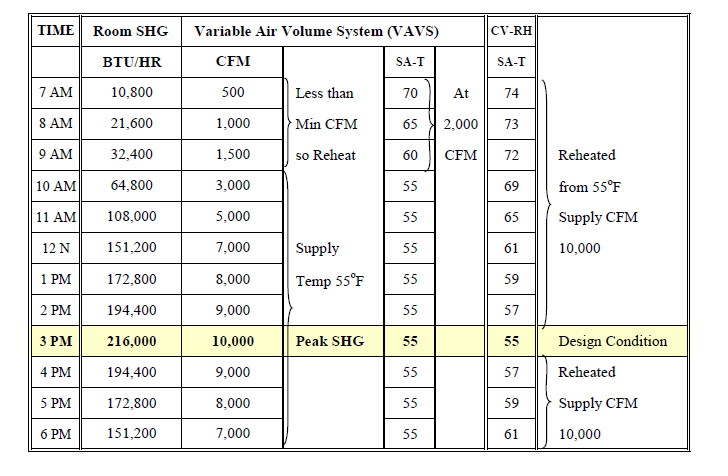

This is called Constant Volume Variable Temp supply system. It is also called Constant Volume Reheat supply system. The supply air is cooled to 55oF to satisfy the hour with the highest cooling load and for all other hours it is reheated to maintain 75oF room temp.

(b) Q-s = SHG / [ 1.08 * (Tr - Ts) ]. SHG = 200,000

Q-s = 200,000 / [ 1.08 * (75 - 55) ]. Q-s = 9,259 cfm

This is called Variable Volume Constant Temp supply system.

| Room Temp oF = | 75 | Max Supply CFM = | 10,000 |

| Supply Temp oF = | 55 | Min Supply CFM = | 2,000 |

Reheating the supply air as a control method for maintaining the required room air temp is not permitted by building energy standards and codes for most commercial type buildings. It is an energy wasting system. In a VAV system the supply air is reduced to offset the reduction in room SHG. Reducing the supply air reduces fan energy and there is no reheat energy. In the case of some hospital rooms, the required cfm is fixed (cannot be varied) and reheat is required.

Return Air (Q-r) quantity is based on maintaining the required pressure condition for the space and the required pressure relationships between adjoining spaces. For example an office space must be at a positive pressure relative to adjoining corridors, copying rooms and storage areas. To maintain a 10% positive pressure 90% of the supply air is returned. So the remaining 10% is transferred to adjoining pace or leave the building through exfiltration. (Supply 100 cfm and return 90 cfm). Example if a photo copying room has to be maintained at 10% negative pressure relative to adjoining office spaces then 110% of the supply air is returned or exhausted. (supply 100 cfm and return or exhaust 110 cfm)

Exhaust Air (Q-e) is soiled, contaminated or polluted air that cannot be re-used and must be removed from the building and disposed of in a safe and appropriate area. Exhaust air must therefore be made up with outdoor air. Minimum outdoor air (Min OA) = Exhaust air. Min OA can be greater than exhaust air if the required ventilation air is greater than exhaust air

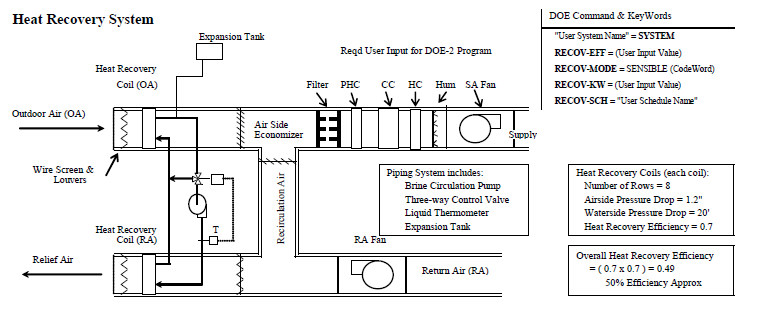

Air from certain areas such as (1) toilets, (2) locker rooms, (3) soiled/dirty clothes/laundry rooms, (4) janitors closets, (4) electrical, mechanical and telecomm rooms and closets, (5) gymnasiums, (6) hospital operating rooms and (7) garages must be exhausted according to building codes and standards. The exhaust air cannot be allowed to come into direct contact with return or outdoor air but the heat from the exhaust air (and relief air if this quantity is high due to ventilation air) can be recovered to preheat outdoor air using heat recovery systems such as run-around-coil systems.

The exhaust air quantity depends on the room conditions. Codes only specify minimum exhaust air requirements. Rooms that have to be exhausted are always maintained at negative pressure relative to the conditioned adjacent spaces. This is achieved by exhausting more air than is supplied or by exhausting air with no supply as in closets. The exhausted air comes from adjacent spaces through cracks around the door or by intentionally undercutting the door to the closet or by providing louvers in the door.

Examples of Toilet Exhaust are: (1) 0 cfm supply with 2 cfm/ft2 exhaust for small toilets, and (2) 1 cfm supply with 2 cfm/ft2 exhaust for large toilets. Any opening between the toilet and the adjacent space will also transmit sound. The solution is to provide a vestibule space (2 doors).

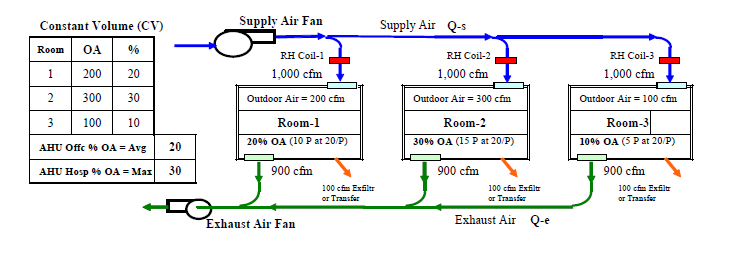

Outdoor Air (Q-o) quantity is determined on the basis of (1) air changes per hour or ACH, (2) CFM/Person, (3) CFM/ft2 of floor area, or (percent of total outdoor air. When an air handling unit (AHU) or System is supplying air to several rooms with different percent outdoor air requirements then the designer must determine the basis for the System or AHU percent outdoor air. It could be (1) the average percent outdoor of all the rooms served by the System as in office buildings or (2) the System outdoor air percent could be set at the room requiring the highest out air as in hospitals. (The System can only have one % OA and not one for each room).

Case-1: Office Building. Use average percent outdoor air of all the rooms.

Room-1 = 20%, Room-2 = 30%, Room-3 = 10%. System = Average = (20+30+10)/3 = 20%

Case-2: Hospital Building. Use percent outdoor air of the room with maximum % OA.

Room-1 = 20%, Room-2 = 30%, Room-3 = 10%. System = Maximum of 20, 30 & 10 = 30%

Case-1: Office Building. Use judgment.

Room-1 = 20%, Room-2 = 30%, Room-3 = 10%. System = 25%

Air balancing.

The supply air quantity was determined to offset the sensible heat gain (SHG) in the space. It was based on a selected ceiling supply air temp of 55oF. The air is discharged through ceiling diffusers that are typically located at a height of 8' in corridors, 9' in residential and 10' in commercial. The supply air will mix with the room air to produce an average 75oF temp at the occupied level range of 0 to 6 feet. In the case of Under Floor Air Distribution (UFAD), 55oF is too low and the SA temp must be raised to 60oF to 65oF and consequently the SA quantity must also be raised. However since the SA is close to the occupants, the minimum SA quantity (ACH, CFM/ft2) can be less than the design standard for ceiling supply. This credit is called Ventilation Effect in ASHRAE Std 90. UFAD is therefore considered an Energy Conservation Measure (ECM).

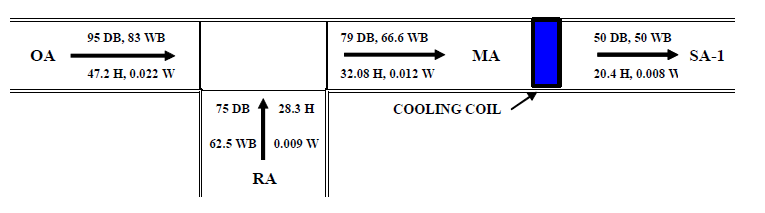

Supply Air Moisture Content. The moisture content of the supply air must offset the latent heat gain (LHG) in the space. The SA quantity has been determined on the basis SA temp of 55oF. This temp may not be low enough so that the SA moisture content will offset the space SHG.

Moisture content of supply air must be less than the moisture content of the room air by the amount of the Room LHG. This is similar to determining the SA quantity based on SHG and a predetermined SA temp of 55oF.

CFM * 1.08 * ( Tr - Ts ) = SHG. CFM = SHG / [ 1.08 * ( Tr - Ts ) ]

Mass Ms (lbs/hr) of Supply Air = Q-s (ft3/min) * 0.075 (lbs/ft3) * 60 (min/hour) = Q-s * 4.5.

Difference in moisture content of supply and return air = Ms * ( Wr - Ws ) * Hfg and this should equal LHG in the space. Hfg is the latent heat of evaporation or condensation of water and steam which is about 1075 btu/b. Wr and Ws are the humidity ratios (moisture content lbs moisture per lb of air) of the room air and supply air.

Ms * ( Wr - Ws ) * 1075 = LHG

CFM * 4.5 * ( Wr - Ws ) * 1075 = LHG

CFM * 4840 * ( Wr - Ws ) = LHG Ws = Wr - [ LHG / ( CFM * 4840 ) ]

Example

Room SHG = 216,000 btu/hr, Room Temp Tr = 75oF, Supply Temp Ts = 55oF

Room LHG = 100,000 btu/hr. Room Relative Humidity = 50%.

Room Humidity Ratio (Wr) = 0.0093 btu/lb (from psychrometric chart)

Calculate the required SA moisture content (humidity ratio W)

Q-s = SHG / [ * 1.08 * ( Tr - Ts ) ] = 216,000 / [ 1.08 * ( 75 - 55 ) ] = 10,000 cfm

Ws = Wr - [ LHG / ( CFM * 4840 ) ] = 0.0093 - [ 100,000 / ( 10,000 * 4840 ) ]

= 0.0093 - 0.0021 = 0.0072

The DP, WB and DB temps at W = 0.0072 is 48oF. This means that the air entering the cooling coil must be cooled to 48oF in order to remove the moisture and then reheated back to 55oF. So dehumidification consumes a lot of energy in terms of refrigeration cooling and re-heating. Typically the room LHG is about 20% and the SHG is 80 %. In an office space LHG is due to people only whereas the SHG is due to outdoor temp, solar heat, people, lighting and equipment.

In the previous example the LHG is 50,000 btu/hr. Calculate cooling coil leaving temp.

Ws = Wr - [ LHG / ( CFM * 4840 ) ] = 0.0093 - [ 50,000 / ( 10,000 * 4840 ) ] = 0.0093 - 0.001 = 0.0083

The DP, WB and DB temps at W = 0.0083 is 53oF. After leaving the cooling coil at 53oF, the temp of the air gains another 2oF to 4oF because of heat gain from the fan motor and in the ductwork. So in most cases no reheat is required.

Example

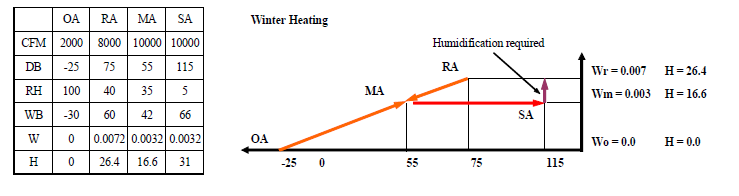

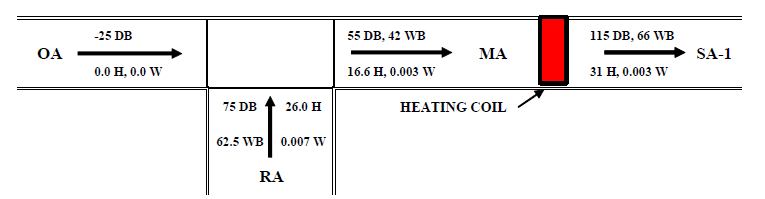

Winter Heating & Humidification

The supply air quantity to a space is determined by the space SHG in summer provided this is not less than the minimum required by code or standard. The minimum supply air quantity required by code can be supplied in winter and the heating can be provided separately with electric, hot water, steam or gas heating devices in the space. In moderate climates there is no secondary heating source such as radiators and the space heating medium is the supply air quantity determined for cooling. The supply air temp range is usually between 75oF and 95oF (low ceilings) to 120oF (high ceilings). The temp is varied to offset the heating load (similar to constant volume variable temp cooling).

In cold winter climates the moisture content outside is near zero and humidification can be a major heating load.

Example

(1) Transmission Heating Load = A * U * ( Ti - T0 ).

Roof: 10,000 * 0.2 * ( 75 - (-25) ) = 200,000 btu/hr

Walls: 2,800 * 0.1 * ( 75 - (-25) ) = 28,000 btu/hr

Windows: 3200 * 1.0 * ( 75 - (-25) ) = 320,000 btu/hr

Total Transmission = 200,000 + 28,000 + 320,000 = 548,000 btu/hr

(2) Infiltration Heating Load = CFM-infltr * 1.08 * ( Ti - To ) Infiltration: = 1,440 * 1.08 * ( 75 - (-25) ) = 155,520 btu/hr

Total Room Sensible Heating Load = 548,000 + 155,520= 703,520 btu/hr.

The sensible heating capacity of 10,000 cfm of air supplied at 115oF =

10,000 * 1.08 * (115 - 75) = 432,000 btu/hr from the Supply Air.

Balance required = 703,520 - 432,000 = 271,520 btu/hr from radiators.

(3) Ventilation Heating Load = CFM-ventil * 1.08 * ( Ti - To )

The 2,000 CFM of outdoor air must be heated from -25oF to room temp of 75oF

Ventilation: = 2,000 * 1.08 * ( 75 - (-25) ) = 216,000 btu/hr

Balance of required heating load by:

(1) Electric Heating Coil = 271,520 btu/hr / 3412 btu/kw = 86.42 kwh.

(2) Heating by Hot Water (HW) Coil:

Entering Water Temp (EWT) = 200oF. Leaving Water Temp (LWT) = 170oF.

Heat given up by the HW = required space heating load

M (lbs/hr water) * SpHt * ( 200 - 170 = 271,520 btu/hr. SpHt (water) = 1. M = 9,050.7 lbs/hr

Convert lbs/hr to gallons per minute (GPM): Lbs/Hr * 8.33 Gallons/Lb * 60 min/hr = 500

GPM * 500 * (EWT - LWT) = Heat Supplied = 271,520 btu/hr. GPM = 18.1.

Humidification

If air is continuously supplied with a moisture content of W = 0.003 to a room that must be maintained at a moisture content of W = 0.007 the room moisture content will decrease and the required room relative humidity will not be maintained. Moisture in the form of steam must be injected into the supply air so that it offsets the decrease in moisture content of the mixed air caused by mixing it with outdoor air that has zero moisture content. Moisture must also be added to make up the moisture loss due to infiltration.

(4) Humidification to offset Infiltration air: Infiltration CFM = 1,440

Q-infltr = CFM-infltr * 4.5 * (Wr - Wo) * Hfg

Wr and Wo are humidity ratios of the room air and outdoor air. Hfg is the latent heat of evaporation or condensation of water and steam which is about 1075 btu/b at room temp. The factor 4.5 converts cubic feet per minute (CFM) of air to lbs per hour. (0.075 lbs/ft3 * 60 min/hr).

Q-infltr = 1,440 * 4.5 * (0.007 - 0.0) * 1,075 = 48,762 btu/hr.

(5) Humidification to offset Ventilation air: Ventilation CFM = 2,000

Q-ventil = CFM-ventil * 4.5 * (Wr - Wo) * Hfg

Q-ventilr = 2,000 * 4.5 * (0.007 - 0.0) * 1,075 = 67,725 btu/hr.

Transmission Sensible Heating = 548,000 btu/hr (52.9%)

Infiltration Sensible Heating = 155,520 btu/hr (15.0%)

Infiltration Humidification Heating = 48,762 (4.7%)

Ventilation Sensible Heating = 216,000 (20.8%)

Ventilation Humidification Heating = 67,725 (6.6%)

Total Heating Load = 820,007 btu/hr = 1,036,000 btu/hr (100%).

Example (100% Ventilation Outdoor Air):

The 10,000 ft2 space described is a contaminated area and all the air supplied must be exhausted (provide 100% outdoor air).

Transmission Sensible Heating = 548,000 btu/hr (25.2%)

Infiltration Sensible Heating = 155,520 btu/hr (7.2%)

Infiltration Humidification Heating = 48,762 (2.2%)

Ventilation Sensible Heating = 10,000 * 1,08 * (75-(-25)) = 1,080,000 btu/hr (49.7%)

Ventilation Humidification Heating = 10,000 * 4.5 * (0.007 -0) * 1,075 = 338,625 btu/hr (15.6%)

Total Heating Load = 820,007 btu/hr = 2,170,900 btu/hr (100%).

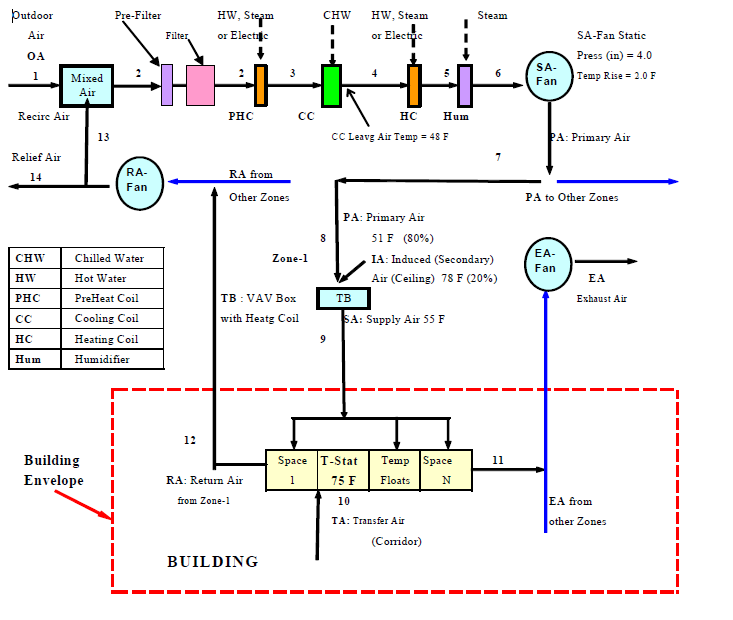

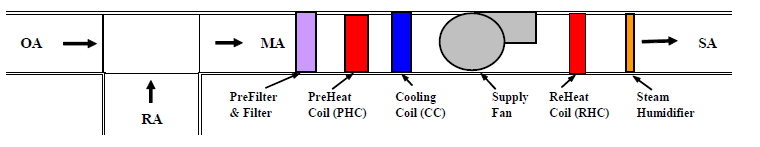

The Air Handling Unit (AHU)

The figure above shows the typical arrangement of equipment components in an Air Handling Unit (AHU). The air has to be filtered and cleaned before it enters the coils. The Filter performance ratings are based on ASHRAE Standard 52. Low efficiency (20%) or medium efficiency (30% to 60%) throw-away less expensive prefilters precede the main filter which has a n efficiency between 85% and 95%. The ASHRAE standard 62 ventilation requirements (example 20 cfm per person for office space) are based on this filter arrangement. The ventilation requirement for an office space can be 5 cfm per person if high efficiency (99%) particulate carbon or ionization filters are used. Hospital operating rooms require high efficiency filters and they also require 100% outdoor air.

In cold climates the stratified outdoor air can freeze water in the PreHeat (PHC) coil. The preferred heating fluid in the coil is therefore steam or glycol. It can be hot water provided precautions are taken to avoid freezing. The PHC could also be electric or a gas-fired or oil-fired furnace as in packaged outdoor roof-top units. The PHC operates in winter only. The Cooling Coil (CC) operates in summer only. The ReHeat (RHC) coil can operate in summer and winter. The humidifier operates in winter only.

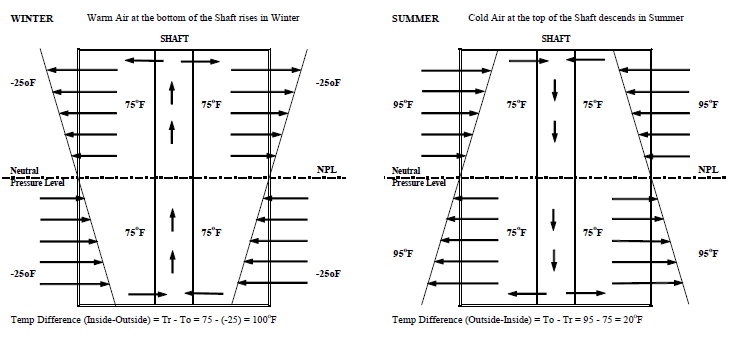

Stack Effect (Infiltration, Exfiltration)

Pressures on buildings due to wind velocity and direction, pressures caused by differences in outdoor and indoor temperatures, building pressurization and the efficiency of the envelope results in exfiltration and infiltration. The pressure difference between the inside and outside can be very significantly in tall buildings. Tall buildings are affected by air movement in the vertical shafts (elevators, mechanical & electrical) due to the phenomenon called "Stack Effect". It is also called the chimney effect which is used to remove smoke or gases from industrial processes. A tall shaft or chimney that is open at the top and bottom causes air to flow into the shaft at the bottom and exit from the top. This effect is stronger if there is also a temperature difference between the air at the entrance and exit.

Temperature differences between indoors and outdoors means air density differences and therefore air pressure differences. In winter the temperature and pressure differences are high and causes infiltration. The warmer inside air enters the shaft at the bottom and rises. It is replaced by cold outside air that enters the building at the bottom. During the summer cooling season, the flow of air is reversed and is generally much smaller because of a much smaller temperature difference between inside and outside. In the case of a pressurized building summer infiltration is insignificant.

The height at which the interior and exterior pressures are equal is called the Neutral Pressure Level (NPL). The location of the NPL at zero wind speed is dependent on the building structure, envelope and construction. It depends only on (1) the vertical distribution of openings in the building envelope, (2) the resistance of the openings to air flow, and (3) the resistance to vertical air flow in the building by the floor construction and floor openings. If the openings are (1) uniformly distributed vertically, (2) they have the same resistance to air flow, and (3) there is no internal air flow resistance, then the NPL is at the mid-height of the building. If there is one extremely large opening between two particular floors relative to the size of the openings between the other floors, then the NPL is close to the large opening.

Multi-story buildings are not air-tight between floors. Floors are penetrated by vertical duct and pipe-shafts, elevator shafts and stairwells. Maintaining air-tightness between floors and between the floors and the vertical shafts is a means of controlling indoor-outdoor pressure differences and therefore infiltration. Air tight separation between floors and between the floors and the shafts is necessary for the proper operation of the air-conditioning system and more importantly smoke and fire control during fires. The shafts act as a chimney spreading smoke to the other floors. Buildings have been designed where all the vertical services (elevators, stairs, shafts) are located on the side of the building and penetrations into each floor is from the side at each floor level. There are no penetrations between floors in this arrangement.

The Pressure Difference (PD) at any level due to Stack Effect can be estimated from:

PD = 0.00027 * (H-NPL - H-level) * ( Tr - To)

H-NPL = height of Neutral Pressure Level (ft)

H-level = height of floor level (ft)

(H-NPL - H-level) = distance between NPL and Floor in feet

Tr - Room Temp (oF)

To - Outdoor Temp (oF)

Example:

Building has 80 floors. Floor to Floor Height = 12 feet. Building height = 960 feet

NPL = mid-point of building = 480 feet. To = -25oF, Tr = 75oF, Tr - To = 100oF.

What is the pressure difference between inside and outside at the ground floor?

PD = 0.00027 * 480 * (75 - (-25)) = 12.9 inches.