Building Science Insight

Glass and Metal CurtainWall Systems

R.L. Quirouette

Foreward

This paper is a reprinted version of Building Practice Note No. 37, entitled "Building Envelope Design Using Metal and Glass Curtain Wall Systems". Notwithstanding some minor differences in the oral presentation, it contains the essence of the talk presented at the Building Science Forum '82. There are, however, a few additional examples of interface connection details between a typical glass and metal curtain wall and other parts of the building enclosure.

In addition to the paper that follows there are several questions and answers relating to the use of curtain wall systems which were taken from the afternoon forum discussions during the Building Science Forum '82. These questions and answers will be found in the last section of these proceedings.

Introduction

Metal and glass curtain wall systems have found growing favor in modern architecture. They are easily distinguished from other types of claddings by their thin mullions of horizontal and vertical metallic bars surrounding an all glass or metal panel. The curtain wall system has evolved rapidly over the last two decades, especially with respect to weather control performance. The early systems presented frequent rain penetration problems; large icicles would form on the outside horizontal bars or condensation on the inside mullion surfaces; glazing seals were sometimes pumped out of the rabbet of sealed double glazing window units. However, most of these difficulties were eventually overcome with improved detail design of the system components. Today, most curtain wall manufacturers offer a quality product line of components which can be. used to create one of the best overall exterior wall systems.

Some difficulty remains, however, in obtaining equal or even adequate performance from the joints at the interface between the curtain wall system and the remainder of the building. Numerous weather control problems are encountered at parapets, soffits, corner details and grade connections. In addition to rainwater penetration and the freeze-thaw action of concealed condensation, cold air seeps into soffits, causing drain pipes, steam pipes, or sprinkler systems to freeze up. Large icicles which form along the roof edge are often a potential hazard to pedestrians below.

Recent field investigations and studies of construction detail design drawings have indicated some practices which continue to cause these problems. Design and construction requirements discussed in this note can minimize undesirable conditions at the interface connection of curtain wall systems to other parts of the building.

What is a Curtain Wall?

A curtain wall system is a lightweight exterior cladding which is hung on the building structure, usually from floor to floor. It can provide a variety of exterior appearances but is characterized by narrowly spaced vertical and horizontal caps with glass or metal infil panels. These systems provide a finished exterior appearance and most often a semi-finished interior as well. They are also designed to accommodate structural deflections, control wind-driven rain and air leakage, minimize the effects of solar radiation and provide for maintenance-free long term performance. Most of today's metal curtain wall systems are constructed of lightweight aluminum, although some may be of steel.

Since curtain wall systems are a good example of building science principles applied to wall design, it may be useful to review some basic principles through the details of a typical curtain wall system.

Design Principles for Exterior Walls

A building enclosure may be broadly defined as a set of interconnecting elements which separate the outside from the inside. These elements would include exterior walls, a roof, other components such as windows and doors, and sometimes exposed floors. The function of a building enclosure is to control the penetration of snow, wind, rain and sun to the inside and to contain the desired indoor climate. The enclosure must meet many individual requirements but for the purpose of this paper they are limited to the following six:

- control of air flow,

- control of heat flow,

- control over the entry of rain and snow,

- control of sunlight and other forms of radiant energy,

- control of water vapour diffusion,

- accommodation of building movements.

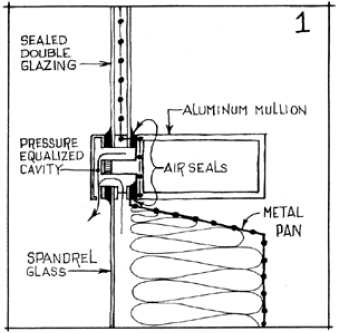

The requirement for air tightness and consequently air leakage control is met by most curtain wall systems because the air barrier of the wall is inherent in the structural properties of glass and aluminum or steel tubes that comprise the system. The continuity of the air barrier (Figure 1) is achieved by the continuity of the glass panel through the air seal at the shoulder flanges of the tubular mullion, and through the aluminum section to the other flange surface. The air seal between the lower shoulder flange of the curtain wall mullion and the metal pan of the spandrel panel provides continuity of air tightness to the air barrier metal pan and on to the next mullion connection. Such assemblies are regularly tested using air pressure to determine the structural properties of the glass, metal, and seals and to determine the equivalent leakage area (ELA) that remains. In addition, the Architectural Aluminium Manufacturers Association imposes upon its members many other requirements including a specification that the system must not leak more than .30 L/s per m2(.06 cfm per ft2) of wall at a pressure difference equivalent to a 40 km/h (25 mph) wind.

Figure 1

Thermal Insulation (Control of heat flow)

The control of heat flow is generally achieved through the use of insulation. Although it is not apparent from the exterior, the curtain wall system uses considerable insulation usually behind spandrel glass or any opaque panels. Because of the materials used in the structure, i.e., glass and metal, which are highly conductive, the system must also contend with potential condensation on the interior surfaces. To curtail this effect, most curtain wall systems incorporate two distinct features: first, a sealed double glazed window or an insulated metal pan and second, a thermally broken mullion, usually with a PVC plastic insert and more recently, a foamed-in-place polyurethane connection. A sealed double glazed window unit can accommodate an indoor humidity up to about 35% at an outdoor temperature of -25oC with little condensation appearing on the glass. Similarly, the thermal break in the aluminum or steel mullion ensures that the surface temperature of the structural mullion will remain well above the dew point temperature of the air for most building types, except for high humidity indoor environments such as in swimming pools or computer centers. The thermal break also ensures that the structural mullion is thermally stable, that is, not subject to extremes of expansion and contraction.

The "Rain Screen" Principle (Control of rain and snow penetration)

To control rain penetration through exterior walls the conventional approach is to seal the exterior façade of the building. However, experience has shown that it is unreasonable to expect perfect sealing of a façade; most sealing strategies require continuous attention and maintenance.

Studies of the rain penetration problem have revealed a better solution than the façade sealing approach. If the air that leaks in and through cracks and crevices of a façade during a rain storm were limited or stopped, most of the water impinging on the façade would migrate straight down the surface and little would penetrate the wall. This is the essence of the "Rain Screen" principle. If an airtight element is positioned behind a façade, the cavity formed between the exterior cladding and the airtight element may reach the same air pressure level as is exerted on the cladding surface, thus removing the force which causes air to flow through any façade opening. The "Rain Screen Wall" is therefore characterized by a cavity behind the exterior surface that is connected to the exterior but sealed tightly, or as tightly as reasonably possible, to the interior. The inner surface of the chamber is usually referred to as the air barrier of the wall.

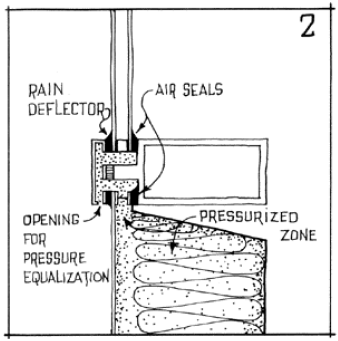

In most curtain wall systems the joint between the infil panel (i.e., window or spandrel panel) and the structural mullion is usually designed to be part of a rain screen system (Figure 2). It comprises a pressure-equalized cavity, connected to the exterior by the drain holes in the exterior caps, and a pressure equalized rain deflector seal between the outside surface of the glass and the mullion cap. The chamber portion of the cavity is composed of the air seals connecting the inside face of the window glass and the spandrel panel metal pan, to the shoulder flanges of the structural mullion and other parts of the structural section. Thus the set of elements comprising the window glass, the air seals, and the aluminum section and metal pan perform the air barrier function for this wall assembly. This design configuration for curtain wall sections has proven successful and has become widely accepted.

Figure 2

Solar Radiation (Control of sunlight and other forms of radiant energy)

Solar radiation falling on building surfaces may have two distinct effects: the first is to cause a significant change in temperature of the façade elements and the second is the slow but destructive effect of ultraviolet radiation impinging on all materials, particularly organic. On curtain wall systems the most important concerns with solar radiation have been the thermal expansion and contraction of curtain wall components, in particular those forming the outside cladding, and the effects of solar radiation on the glazing elements. A warping of glass occurs due to differences in temperature between the inner and outer panes, while pumping results from expansion and contraction of the air in the cavity of the sealed units. Daily and seasonal temperature differences can also cause this effect. The action of the window (thermal pumping) is particularly stressing to the inner air seal; however, serrated edges or recessed flanges keep the seals from pumping out. Most of the ultraviolet-sensitive materials in curtain wall systems are located in the pocket and cavity areas of the joints and are partly shaded by metallic and glass components.

The Vapour Barrier (Control of water vapour diffusion)

Water in its gaseous phase (water vapour or humidity) always tries to migrate from a region of high water vapour pressure to a region of lower pressure. The migration of water vapour through a wall can be compared to heat flow; it moves through all materials at a rate that is dependent on both the resistance of the materials to water vapour flow and the difference in water vapour pressure on both sides of the material.

The migration of water vapour through an assembly of materials is not a serious problem in itself, provided it does not condense to liquid form in the material or wall. If water vapour is likely to condense in a wall, the principal defense is to restrain its migration by using, a "vapour barrier" with a high water vapour flow resistance, positioned on the warm side of the insulation material or wall assembly.

The migration of water vapour through a curtain wall assembly is checked by the vapour barrier qualities of the glass and aluminum, as these materials have near perfect vapour flow resistance for all practical purposes. Thus the inner pane of the sealed double glazed unit and the aluminum or steel inside surfaces of the mullion provide the necessary water vapour diffusion control. Sealants also contribute to the continuity of the vapour barrier.

Joints and Tolerances (Accommodation of building movements)

Movements of the structural elements of a building must be determined prior to the design of an exterior wall system. Movements may be grouped into three types:

- live load deflections due to occupancy loads or peak wind loads on the building façade, and dead load deflections of the building structure,

- expansion and contraction of materials as a result of temperature, radiation and sometimes hygroscopic loading,

- slow but inexorable movements due to gradual deformation, such as creep in concrete, foundation settlement, etc.

Although not a frequent cause of failure, building movements are not adequately considered in the design and construction of façades. Masonry that has cracked or bulged, metal siding that has sheared its fasteners or buckled, or caulking that is completely squeezed out or broken are some of the effects of building movement.

With curtain wall systems, the basic element which must be accommodated is the glass panel. Around it, the typical curtain wall system of structural tubes, pressure plates and caps allows for a differential movement of about 4 to 5 mm (3/16 to 1/4 in.) on a floor to floor basis and between each vertical riser. This tolerance will accommodate most building movement resulting in compression, expansion and parallelograming of the frames. If the curtain wall system must accommodate a potentially greater movement than above, it is likely that another system of mullion extrusions will be required. This inevitably leads to more complex detailing and usually a disproportionate increase in the system cost.

Designing the Interface 'By Others'

Assuming that most curtain wall systems can perform well or that the components are available to build a quality wall system, we turn our attention to the connections or the interface joint between the curtain wall system and the other parts of the building.

The Parapet

When a curtain wall system is designed to extend upwards past the roof line and thus to get cold, several potential problems must be considered. Without proper termination at the head of the curtain wall system, condensation and frost may form in the tubes and eventually drain to the inside of the building, or icing may force parts of the parapet cap off the building. Also, if allowed to fluctuate with the outdoor temperature, the structural part of the curtain wall system may expand and contract beyond its design limitations, thus straining all connections in and around the parapet elements.

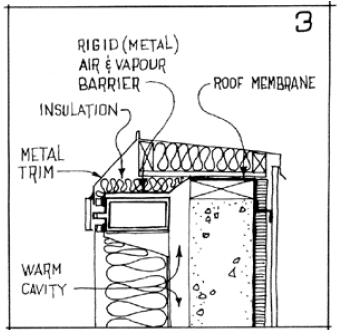

Because the structural tubes of the curtain wall system are also miniature chimneys, particularly in high-rise buildings, they may conduct large volumes of (humid) air to the outside if left open or unsealed at the top. As there are many joints in the structural system of the curtain wall, it is preferable that the air barrier component be connected from the top shoulder flange surface of the horizontal mullion and that it be made to bridge the gap from the curtain wall and parapet structure to the air barrier component extending from the roof deck (Figure 3). This may be difficult at times, particularly with a conventional built-up roof in which the insulation is under the membrane and must cross over somewhere in the interface detail. Also the air barrier between the curtain wall and the parapet must be insulated on the outside to prevent any condensation from forming on its inside surface.

Figure 3

Those parts of the structural mullion tubes from the thermal break and inward, must be kept on the warm side of the wall at all times. Hence the structural mullions should face a warm cavity. It is not recommended that insulation be placed against the mullions or within the mullion tubes. A parapet cap can then be designed to cover the parapet connection. It should be sloped to the roof side and pressure equalized to minimize rain entry. This design approach applies to all types of parapets, whether backed up by brick, block, precast or wood structure.

The material used to construct the parapet air barrier is of particular importance. While this air seal may be a flexible membrane, it must be able to carry air pressure loads as high as the combined wind load, stack effect, and ventilation pressure or it will rupture and cause a major air exfiltration problem. It is better to use a rigid material such as sheet metal with appropriate connection details because the insulation on its outboard face must remain in place.

The Corner Interface

Buildings using curtain wall systems are often required to form an inside or outside corner. When two sections of curtain wall meet, the interface detail must be designed to provide control over all of the aforementioned requirements. Because corner details vary considerably from project to project, suppliers do not have stock sections to draw upon to construct this interface detail. However, curtain wall suppliers will fabricate the necessary interface components provided that their participation is solicited early enough in the planning phase, preferably before tenders are closed.

This interface detail will require an air barrier, some insulation and an exterior cladding (Figure 4). The air barrier must be structurally adequate to carry the air pressure loads on that corner. The material to be used as an air barrier should be aluminum if the curtain wall system is aluminum, or at least a sheet of metal, and at the very least a rigid element. Galvanized sheet steel may be used with aluminum; however, consideration must be given to the corrosive potential of dissimilar metals. Bond breakers such as paint or butyl tapes have proven satisfactory to many of the curtain wall system manufacturers. If the outside cladding down the corner of the building is to appear as a continuous strip with no mullion interruptions, then care must be taken to develop an air seal joint at the ends of the air barrier sheets.

Figure 4

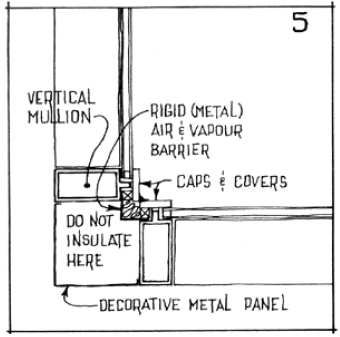

When dealing with an inside corner, the same requirements apply.(Figure 5). However, if the mullion caps are in near contact or overlap slightly, it is not necessary to add a further "Rain Screen" baffle over the insulation. The air barrier should be rigid and sealed against the shoulder flanges of the vertical mullions and held in place by suitable pressure blocks. The final architectural solution may require a decorative finish inside to follow the dotted line profile. This space should not be insulated, otherwise the structural air barrier becomes a vapour barrier on the wrong side of the insulation, inviting condensation problems.

Figure 5

The Grade Connection

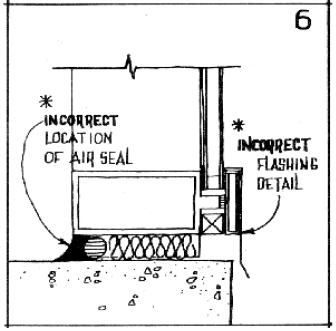

Whether on a concrete curb, a block wall or a concrete floor slab edge, the grade connection interface between the curtain wall and the remainder of the building is particularly sensitive to rain penetration and air infiltration. The most common interface detail is shown in Figure 6. This design approach often results in two performance problems: first, cold air infiltrates through the ends of the vertical tubes, increasing the potential for condensation on the tube surfaces and for glass breakage, and second, rainwater accumulates in the cavity between the curtain wall section and the floor, which will prematurely deteriorate the floor-to-mullion air seal.

Figure 6

In keeping with the design requirements for continuity of the air barrier, it must be started from the horizontal mullion lower shoulder flange and extended directly to the floor or curb as in Figure 7. A sealant might be used to create a sloped edge or a water dam, and a small amount of insulation will control any condensation forming on the warm side of the air barrier surface. Then a flashing component should be installed over a pressure block and under the snap cap. This will ensure that surface water draining from the panel above is directed to the outside of the cavity instead of into it.

Figure 7

The Masonry Interface

In the recent past there has been a trend in architectural practice to devise new ways of obtaining the flush façade. Specifically, window glass is often aligned or nearly aligned with the exterior veneer or cladding to create a smooth unsculptured exterior wall. Several general design weaknesses have been found in this type of interface joint, between the masonry and the curtain wall systems. Most often the detail shown in Figure 8 results in condensation on the inside mullion surface and efflorescence on the outside surface of the brick veneer. The reasons are twofold : first, the wall insulation is out of line with the thermal break of the curtain wall mullion. This results in a discontinuity of the insulation plane and creates a thermal bridge that allows part of the interior structural or metallic components to become cooler than the inside dew point temperature. Condensation often shows up on the inside surfaces of the sill mullions. The second reason is a discontinuity of the air barrier, because there was no provision for an air barrier element in the masonry wall; if there is an air barrier, it may be attached to the wrong part of the curtain wall mullion.

Figure 8

This configuration allows cold air which has entered the cavity from the weep holes in the brick veneer to infiltrate past the mullion connections and into the vertical tubes. If this detail occurs in the upper part of a building there would be a tendency for air to exfiltrate from the room. If moist, warm air finds its way into the cavity between the brick and the concrete block, most of its moisture would condense on the back of the brick veneer. This shows up as severe efflorescence on the brickwork just below the window during the spring thaw; sometimes the brickwork will spall and crack.

This interface detail must be designed so that, regardless of its exterior appearance, an air barrier element is connected from the shoulder flange of the curtain wall mullion to its complementary component on the masonry wall assembly. This may be the gypsum board on the room side face of the block wall or it may be a trowelled-on mastic in between a layer of insulation and the backup block wall. Some element must be chosen to carry the full wind or pressure load that may occur across the building wall at that location.

The trowelled-on mastic has vapour barrier qualities, but it is not considered an adequate air barrier under any circumstances. Even a pinhole in the mastic will allow air to seep in between it and the insulation. If the insulation is not air-permeable, the air will exert pressure on it, and in some cases, force it off the wall.

In the design of this interface detail, it is also desirable that the wall insulation and the curtain wall mullion thermal break be aligned. If this is not practical because of a particular design appearance requirement, then the interface detail must provide sufficient space so that the blanket of insulation may bridge the gap from the insulation on the masonry wall to the thermal break of the curtain wall section. The insulation should be installed tightly on the cold side of the air barrier component, which should have some vapour diffusion control qualities as well.

When this represents a sill detail, the sill flashing connected to the curtain wall mullion must reach over the brickwork and have the appropriate drip profile. This flashing should not be connected on the inner shoulder flange surface of the curtain wall section as it will cause a thermal bridge to occur at the air barrier connection. Similarly the flashing should not go over the cap or be fastened to the cap surface, as more water than necessary will penetrate the cavity between the curtain wall and the masonry. The sill flashing will perform best if it is installed over the pressure block, held in place by the pressure plate and cap. There are also other types of extrusion to suit this application.

The Precast Panel Interface

At times a curtain wall is used in a building façade system with conventional precast panels. Vertical strips of precast panels are interspaced with vertical strips of windows or horizontal strips of precast panels can be interspaced with horizontal strips of windows to create a layered effect of glazing, precast, and glazing.

In these combination systems several questions should arise during the design phase: first, will the curtain wall system be connected to a pressure-equalized wall or a precast panel wall using the face seal approach and second, does the sequence of construction allow for the successful assembly of the interface joint?

Consider the following: a precast panel enclosure must be connected to a curtain wall system assembly. The sequence of construction might be as follows: the precast panel is erected first on the building and aligned; then the structural elements composing the curtain wall system or window system are mounted and installed; finally, an inner wall is built behind the conventional precast to complete the wall assembly. As simple as it might appear, it is likely that the interface components which connect the curtain wall system mullion to the precast panel face will not be constructed as intended. This is because the interface components (see Figure 9) which must be installed last, an air barrier, insulation and a cladding detail, require that two subcontractors, a drywall contractor and a curtain wall installer, work on the interface joint at the same time. It invariably means that a swing stage will have to be used again, and part of the curtain wall will have to be dismantled.

Figure 9

In these cases it is imperative that the general contractor work closely with the designer to arrive at interface detail which is buildable within the sequence of construction and that this detail embody all the elements required of exterior wall design.

The Steel Siding Interface

When connecting an aluminum curtain wall system to a steel siding, some thought must be given to the long term corrosion potential of the connecting elements. If a steel air barrier component is used to connect the curtain wall system mullion to the steel siding, the connection should not corrode appreciably. This is because the connection is on the warm side of the thermal break and should not come in contact with much moisture. Also it is likely to be separated from the aluminum by a tape or caulking material. However, if a stainless or galvanized steel element is used to connect the steel siding to the aluminum curtain wall mullion on the outside of the pocket pressure block, some measure of protection is required at the interface between these two dissimilar metals. A tape, special paint, or a vinyl gasket, can prevent the stains which so often occur when rainwater washes off the oxidized metals at this interface connection. It is also important to consider the type of material used for the pocket pressure block. This block should be of some plastic material to inhibit any corrosive action of the materials in contact with it or with the aluminum.

The Soffit

This part of the building is perhaps one of the most troublesome and misunderstood parts of the building enclosure. First, it must be determined whether a soffit is to be heated or unheated, as most design decisions must be based on one or the other of these premises.

In the event that the soffit is to be heated, then the enclosure area of the soffit, which includes the lower part of the wall façade and the underside surface of the soffit, must be designed to meet all the requirements of an exterior wall.

Most often there is a discontinuity of the air barrier because the point of attachment for the air barrier component is wrongly chosen. Also, the soffit portion that faces the warm cavity is the site of cold air infiltration because of the inadequacy of the air barrier component to handle air pressure loads even under the mildest of wind conditions. A polyethylene film with taped joint over a layer of insulation is inadequate for controlling air movement in and out of the soffit.

In the design of a soffit system, the ends of the curtain wall vertical tubes and the horizontal section must have a structural air barrier attached to the lower shoulder flange of the mullion face; the barrier must return to the underside of the soffit to link up with its counterpart in the soffit construction (Figure 10). This should be followed by careful detailing of a continuous insulation layer from the thermal break joint at the curtain wall mullion, around the mullion section, to join eventually with the soffit insulation. Depending on the design humidity conditions, a vapour barrier may or may not be required, but if it is, then care must be exercised in the choice of material and location.

Figure 10

In the event that a soffit is to be unheated, most of the building envelope design requirements must be achieved at the roof/floor element. In this case, it would be wise to consider a complete discontinuity of the structural components of the curtain wall system composing the façade so that no vertical tubes in the soffit area are connected to the corresponding vertical element starting at the floor above and going up the façade of the building. An alternate approach is to construct a narrow vertical enclosure around the curtain wall system facing the soffit cavity so that the curtain wall system is maintained in a warm environment at all times and is properly sealed and insulated.

Soffit design and construction is somewhat complicated by the sequence of events that must take place during construction. The sequence must be clearly delineated by the designer and builder in order to achieve quality performance for this area. Icicle formation under soffits, wet surface finishes, frozen sprinkler pipes, and drafty lower floors are but a few of the problems that have been reported with improperly detailed or improperly constructed soffit zones.

Sloped Walls (Glass Roofs)

Architects and owners want to see through their roofs. Skylights, and atrium and mall spaces are to be bright, open and clear and at the same time provide all the functions of a normal roof. The first attempt at constructing sloping glass walls using conventional mullion sections revealed the major weakness almost immediately. Because of the angle at which the mullions rested, the cavity could not drain and the window unit glazing seal could be continually immersed in water. This caused two problems: it destroyed the inner air seal, which eventually allowed rain to penetrate, and the glazed sealed window unit failed prematurely because the edges were frequently immersed in water. In addition, it was discovered that if sloped walls were constructed in humid environments, severe condensation would form on the glass surfaces, accumulate at the lower edge, and drip from the horizontal bars.While this was not a serious problem, some measure would have to be taken to control the effects of condensation.

These difficulties were corrected in most systems by the introduction of new mullion sections which provide an interconnected rain gutter system with drainage to the outside that is well below the primary air seal of the glass and aluminum. interface (Figure 11). Also most of these new sections have condensation collector gutters and some manufacturers may soon provide an inside drainage system for the condensation collector, especially for high humidity environments where excessive condensation may form.

Figure 11

The interface connection between a sloping glass wall and other building elements is somewhat complex. However, if the sloping wall abuts a vertical wall that rises above the glass roof, the air seal requirement is the same as that for all of the interface details. An air barrier element must be joined from the flange surface of the horizontal mullion to the similar function element of the adjoining wall. The air barrier must be insulated from the outside and a protective cover installed over the insulation. This cover must also serve another purpose. Because of the possibilities of snow accumulation, the cladding cover should extend sufficiently high up the vertical wall to guard against a water dam buildup at the upper edge of the glass roof and over the cladding joints. This cladding should be one piece where possible and may connect to the normal mullion cap; however, it is probably better to extend it over the cap of the sloping glass curtain wall mullion and fasten it to the mullion face cap.

Where two sloping glass walls meet as a hip roof, the air barrier, insulation and cladding cover should be designed as a single element to form the ridge.

Where a sloping glass wall is required to interface with a vertical glass wall from underneath, consideration must be given to melting snow and ice formation at the edge, and to the condition and continuity of drainage from the sloping roof mullion drain gutters to the wall mullion sections below.

Summary

The interface detail often referred to 'by others' will require a thorough well-developed design solution based on all the principles of wall performance. Consideration must also be given by the general contractor to how he will implement the construction of the details developed by the design team. The sequence of construction is particularly important for a successfully performing interface detail.

The interface joint, be it a parapet, soffit corner, or connection to another type of wall, will require a structurally adequate air barrier securely connected to the curtain wall at its proper location and joined to a material of similar function at its other end. The air barrier component should be rigid so that insulation can be brought into intimate contact with its surface. In most cases the insulation will require a protective cover and this usually becomes the outside finish or cladding. The cavity between the outer cladding and the inside air barrier should be pressureequalized and drained to the outside. If the air barrier material has a sufficiently low permeability to water vapour flow, it will act as a vapour barrier; otherwise a separate vapour barrier may be required.

On very large projects where the designer intends to use much curtain wall, it will be best to obtain the services of a building science consultant during the development of working drawings and perhaps at the preliminary design phase.

Additional Reading

R.L. Quirouette, A Study of the Construction Process, Division of Building Research, National Research Council of Canada, Building Practice Note 32, 1982.

This article was published as part of the technical documentation produced for Building Science Forum '82, "Exterior Walls: Understanding the Problems", a series of seminars presented in major cities across Canada in 1982.