Energy Programs and Case Studies for Teaching

CONTENTS

- Introduction (case studies and using energy programs)

- DOE21E Energy Program by USDOE

- eQUEST and the DOE2.2 Energy Program

- Energy-Plus Program by USDOE

- Trane's TRACE and Carrier's HAP Energy Programs

CASE STUDIES

- 1. Case Development Plan

EXAMPLES

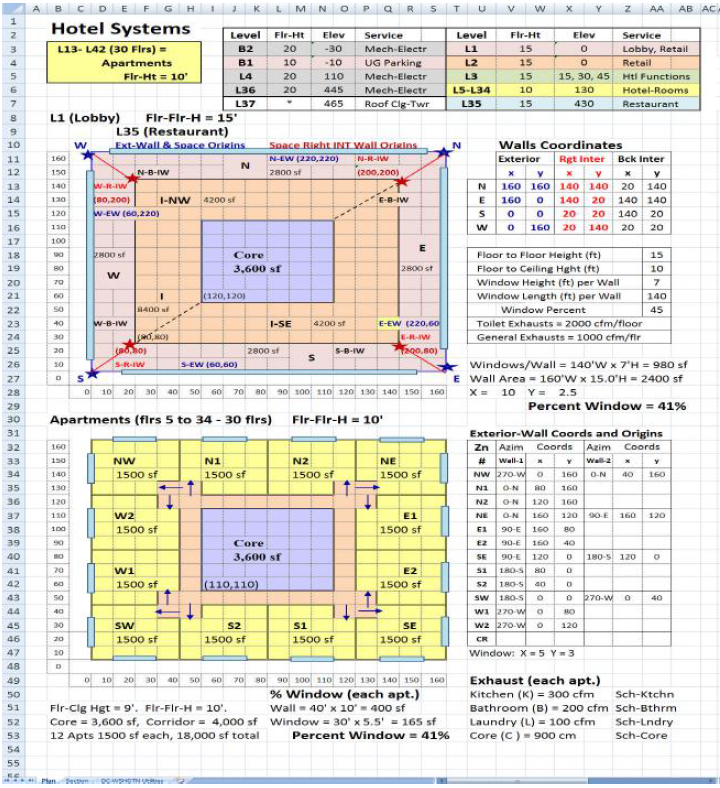

- Hotel Systems

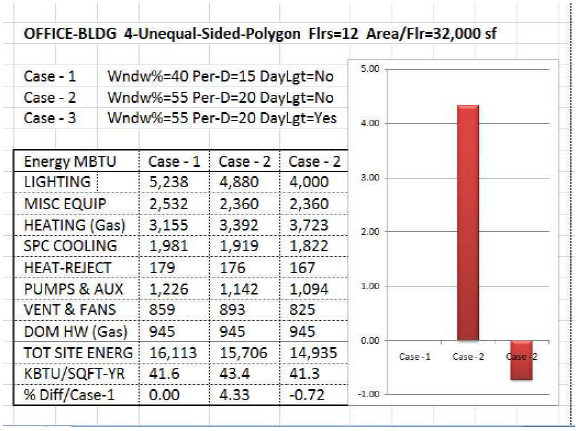

- Office Floors

- High-Rise Mixed-Use Bldg

- Middle-School and Community Center

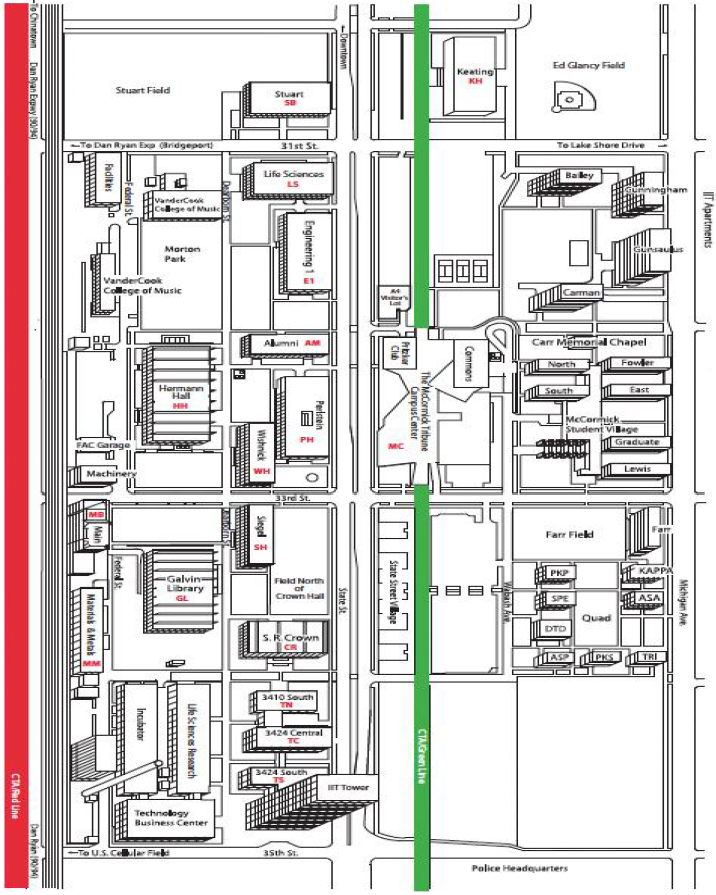

- College Campus

1. INTRODUCTION

Case Studies for Teaching

Computer programs for energy analysis today are required to show compliance with building energy code. They are also used for LEED certification. The Energy Cost Budget method considers Demand costs based on Time-Of-Use and Seasonal utility rates. This requires all four phases of the program – Loads, Systems, Plants & Economics.

A Life Cycle Cost Analysis (LCCA) program is required to make final decisions. This requires cost information and cost estimating programs for first, maintenance and operating costs. Few design firms perform LCCA because reliable cost data for Energy Conservation Measures (ECM) is not readily available. Final decisions regarding systems, plant and equipment (in some cases rejecting the energy analysis results) are therefore mainly based on engineering experience.

The results of energy programs are not used in design and therefore not used in construction and operation. Energy program results are used to compare alternative design options and make decisions when selecting envelope, systems and plant. They are also used to show energy code compliance and for sustainable buildings certification.

Design decisions are also based on

- first & maintenance costs,

- reliability & durability of systems, plant and equipment,

- ease of operation and maintenance,

- availability of parts & maintenance staff at the location

- environmental impacts

Ideally, energy programs should be easy to learn and use in order to prevent misuse of the program and to keep Architectural Engineers Design (AED) costs down.

Case Studies of different building types with their energy conservation options are the best way for teaching and learning correct use of building energy analysis programs from a whole project perspective. Besides whole project examples, examples of how to perform different and specific tasks are required. This also levels the playing field in ensuring the correct use of the program for code compliance and LEED certification by all users.

The DOE2.2 (unlike DOE2.1E) manuals give few examples showing project-specific applications of using commands and keywords. There is presently no database of case studies for learning the use of eQUEST. eQUEST training manuals explain the basic use of the program. Customer support consists of a users group that provides short words and sentences (in English) of advice.

Most of the case studies posted on websites and magazine articles consist of final reports only and are intended to promote the AE design firm. No details of how they were analyzed (their design and modeling secrets) are provided.

A database of case studies covering different building types and sizes in different locations based on real projects should be developed by the industry. The same case studies projects should be analyzed with different programs (DOE2, Energy-Plus, TRACE, HAP) and they should give approximately the same results.

The purpose is not to compare and check programs. The purpose is to ensure that they are all used correctly and users of different programs are on the same playing field. This ensures that one program does not produce more energy savings because of user ignorance and incorrect use.

The Use of Building Energy Analysis Computer Programs

The use of energy computer programs was not mandatory until States introduced energy codes. Except for California and Florida, most States introduced codes just before the deadline of 2004. Federal buildings had 10CFR434 which does not have to be as stringent as ASHRAE Std90. LEED certification is not mandatory. Energy computer programs were therefore not used on most projects until the introduction of codes.

All architectural-engineering design firms (AEDs) in the USA must now have expertise in the use of at least one of the major recognized energy computer programs or they have to subcontract this work to a firm or individual that does.

With easy to use windows, graphics and forms interfaces to energy computer programs today (which did not exist until the late 1990s or they would have used earlier before codes), energy programs are now also routinely and frequently used to evaluate Energy Conservation Measures (ECMs) and to make design specific decisions at the beginning of the project.

With the goal towards low (or net-zero) energy buildings, non-conventional and innovative designs of a building (envelope, lighting, day-lighting, HVAC systems, and DHW), energy computer programs now play a very important role. Previously decisions on building construction, systems, and equipment were based on the experience of architects and engineers which can vary considerably.

Responsibility for Energy Analysis

Energy program users are mainly Architectural-Engineering Designers (AEDs) that use the programs on real building projects. They are also used by academic institutions for teaching in the classroom and for research. The success and value of energy programs should be measured by its use on real building projects for design-evaluation, code-compliance and LEED-certification.

AEDs have this responsibility and they should be involved in the design and development of energy programs and not just academia, research institutions, and software firms that are not involved with real buildings. However, AEDs time and cost have to be chargeable to projects and therefore their involvement in program development is minimal. In my experience when you are involved with real projects there is no time to think of extra-curricular activities. This has resulted in programs created by academics and researchers (who have no experience working on real building projects) that over-emphasize theory and underscore the practical aspects of using the program on real building projects.

The Cost of Energy Analysis

The staff involved in the architectural-engineering design (AED) process consists of architects (design, technical and project management) and engineers (civil, structural, mechanical, electrical, lighting, plumbing and fire protection). A million square feet building typically goes through the phases of Preliminary Design (PD), Schematic Design (SD), Design Development (DD), Construction Documents (CD) and Construction (checking shop drawings and site visits).

Relative to the total cost of the AED process of major projects, the cost of energy analysis and code compliance are not significant. The energy analysis cost and time, relative to the total design time, might increase with decreasing total building floor areas (size of building).

One million sqft office bldg (40 stories at 25,000 sqft/floor) in a large city downtown (including the land) costs $250 million at $250/sqft. The A-E design fee is 3% or $7.5 million. At an average A-E labor cost of $100/hour (including overheads), the design time is 75,000 hours. Energy analysis of an office building using eQUEST or TRACE takes about 100 hours (2.5 weeks at 40 hours/week) or 0.13 % of A-E design time only or 0.004% of total building cost.

The results of energy analysis are not used in the design process. Design affects the building products (equipment), construction and operation. Building energy analysis programs therefore do not significantly impact the building process. California and Florida had energy codes before the year 2000. All other States introduced energy codes after 2000. Computer energy analysis before the year 2000 was rarely done but the buildings were designed for efficient energy use.

Energy analysis for LEED certification adds to this cost and time because it requires more documentation and other administrative processes over above that required for code compliance.

Teaching Energy Analysis

It is difficult to document how to use a program where the input data is entered through forms. The forms have to be reproduced on paper showing the right input entries for the job and this information can be scattered across several forms. The Building Description Language (BDL) method of input of USDOE's DOE2 and Energy-Plus programs also represents a description and specification of the building that is being modeled. The BDL explains how it is done.

Checking the results after the program executes, but is used incorrectly, is difficult and time-consuming. Case Studies of different building types provide a reference basis for checking new projects to ensure the results are within acceptable and expected limits.

Building energy program users must have a thorough knowledge of the architectural and engineering basis of the program. They must also understand the full scope (input requirements and output reports) of the program before applying them on real projects. These programs will generate results if the modeling of the project is inappropriate or wrong.

The heating, cooling and fenestration chapters of the earlier ASHRAE Handbook of Fundamentals in the 1970s and 1990s could be used in the classroom to teach this subject of envelope performance. The CLTD-SCL-CLF method that is based on tables showing performance of envelope materials under different conditions demonstrated how the materials affected loads.

The 2005 Handbook, describing the heat balance method, is not suitable for teaching this subject. Relative to the energy consumption of large commercial buildings, the envelope loads are not significant. The greater accuracy of the heat balance method over the transfer function is not going to make a big difference on large projects when comparing energy alternatives. It is significant when analyzing and comparing specific building materials and systems.

Understanding the mechanical and electrical theory of energy analysis and the skill to apply it correctly requires an engineering degree or diploma. Decision-making based on the results requires years of project engineering experience.

Defaults and their Potential Misuse

eQUEST Schematic Design is an example where all the engineering design data is presented as defaults by the program given the building type. The user has to enter the building and zone shapes and dimensions which can also be done by tracing AutoCAD drawings. It is possible to use this program without knowing the subject in theory or practice.

Someone that does not have AE design experience or have basic engineering knowledge of all the components of "Loads, Systems, Plants and Economics" of energy programs can use the defaults that might be inappropriate for the project. The program will still run and get results showing energy savings over ASHRAE Std90. It is difficult and time consuming to check this.

Today, nearly all heating and cooling loads calculations are done with computers and not manually. It is possible to use computer programs by understanding just the input terms and without understanding how this input affects the results from computer programs.

This is not like driving a car without knowing how it works. The analogy is the car designer and engineer. Architect and engineers are designing and creating the building with its mechanical and electrical systems and faulty design affects the building user.

Mechanical engineers with an HVAC background are qualified to use energy programs. Architects and other building engineers need to understand the theory, especially of HVAC, power, and lighting, before they can claim to be able to perform energy analysis. Architects are concerned mainly with envelope design.

Choosing an Energy Analysis Program

The best energy program to use in AED offices is not necessarily the one with the most "Xs" in the capabilities columns in the report "Contrasting the Capabilities of Building Energy Performance Simulation programs v1.0". Ease of use, financial stability of the program vendor and customer support are determining factors. The report does not consider these factors.

Financial stability of the vendor is important because engineering programs are expensive to develop, maintain and support and the number of customers are few. In the past USDOE provided this stability and the DOE2 program represented the energy program standard.

eQUEST (based on DOE2.2) is now the most widely used program for code compliance and LEED certification. It now represents the unofficial standard. This is not because of the number of "Xs" (which it does) in the Capabilities report, but because of ease of use. It also has the advantage of being free to the public worldwide except in California since program development is supported by California tax payers.

The Energy Program Software Business

Developing, marketing and supporting energy (and engineering) programs are not profitable businesses for the private sector. The number of potential customers is few and they are not willing to pay more than the cost of, say, and MS Office program which would be less than $500 per copy. This industry cannot support more than two or three competitors in this field.

Regarding an open source energy program by a non-profit group, it would have to compete with the eQUEST program based on DOE22 which is free and appears to be well funded by California utility companies that make their money selling utilities, not energy programs. The eQuest interface is privately owned. I am not sure that it's calculation engine, DOE22, is.

It would have to compete with TRACE by Trane and HAP by Carrier which are also well funded and they can justify their costs because the software also promotes their main HVAC equipment products. In my opinion, TRACE and HAP are practical programs that engineers can relate to, because they were developed by people involved with real projects.

One of the advantages of using TRACE and HAP is excellent customer support whereas eQUEST and DOE22 have no customer support. TRACE and HAP also assure long term stability. An open source DOE21E energy program still requires a GUI and graphics interface like Visual-DOE and Energy-Pro. In my experience this interface development is more difficult, time consuming and expensive than developing the engineering model and analysis.

A non-profit association of AEDs could possibly support the development of interfaces to the publicly funded programs of DOE21E and Energy-Plus. This would be the basis of open source energy program. It would consist of the input and output interface, comprehensive documentation, case studies & examples and teaching & learning materials. In the past, a nonprofit association of architects and engineers scattered worldwide tend to be slow and bureaucratic in developing programs.

Alternatively, a non-profit association could support privately developed interfaces like Visual-DOE, Energy-Pro and Design-Builder with documentation. customer support and training. This is the biggest cost of the engineering software business which has a small customer base and revenues. Until recent years, almost all such private firms eventually failed when they also had to compete Trane's TRACE and Carrier's HAP.

Required Features of Energy Programs

Some of the programs developed outside the US might have the advantages of importing Autodesk CAD and BIM models. They might have useful design features such as CFD, etc., but they cannot yet compete with the DOE2 based and other US developed programs for code compliance in the USA because of limitations in Systems, Plants and Utility-Rate-Analysis.

The information required by energy programs does not have to include the precise details shown on construction documents. It is easier to enter energy program input directly than to import detailed data from CAD and BIM models which are going to come with large quantities irrelevant data.

The eQUEST feature of being able to trace AutoCAD drawings (discarding irrelevant layers of text etc.) is all that is necessary. It ensures fast accurate physical modeling.

The Design Phase

Energy programs are external to the design process. They are used to compare alternatives and make early design decisions. The results are not used to generate construction drawings. The results from manual procedures and design computer programs and equipment selection from catalogs and selection programs are used in the design process. The results of energy programs are therefore not used in the construction and operation phase either.

The design process considers every item that consumes energy separately such as stair pressurization fans, escalators, etc. Energy programs only consider major items and they are all approximately lumped under equipment loads in watts per square foot and equipment gas and fuel oil usage in energy per square foot. Examples are shown in the figures.

The greater theoretical accuracy features of Energy-Plus described earlier over DOE21E are not going to be considered by practitioners unless the computer program make the design process easier, faster, more efficient and less expensive and do not add to design time.

CAD programs have definitely made the drafting process more efficient and reliable. They have made a big difference to inter-disciplinary space integration. Programs such as CFD add to the cost of the design process.

Theoretically Accurate Calculations

There was minimal use of computers through the 1980s until cheap PCs became available in the 1990s. Extreme theoretically computer calculated accuracy of energy programs is still not as important as engineering judgment and experience during the design process.

The 102-story Empire State building was built around 1930 and several large commercial buildings have been built since then through the 1960s without the aid of computers. There were no spreadsheets or calculators – just slide rules.

There is no such thing as an accurate energy analysis program. Relative accuracy when comparing building components, loads, systems, equipment, plant of Energy Savings Option (ECO) is required and important. EnergyPlus does not produce better, superior or more accurate results compared to other energy programs such as DOE2 when the results are compared to the completed building in operation.

In the case of large commercial buildings, the actual energy consumption by the completed building is almost always higher than the energy use predicted by all energy programs. A-E design firms sell their services to clients showing the energy efficiency of their building design.

EnergyPlus, with its extreme theoretical accuracy, probably shows the lowest energy consumption. The A-E design team has to explain to the building owner why the actual building energy use is much higher than their design estimate after the building is in operation. This can be interpreted as deceiving the client to get to design the project.

All this accuracy is to maintain every individual in a building and space perfectly and exactly comfortable at all times. The occupants in a space would include a mix of different ages, health conditions, ethnic backgrounds (from hot & cold countries), moods (calm & angry), etc. Until 100 years there was no air-conditioning and fireplaces were used for heating in cold countries. Humans survived. After all this extreme program accuracy the results of EnergyPlus can be off (usually too low) from the measured performance of the building in operation.

Maintaining Exact Comfort Conditions

Judgment and experience are applied throughout the design process. Besides weather, it is not possible to predict the precise internal scheduled loads of a building. The trend has been that, while lighting loads have decreased due to standards and codes and new technologies, the receptacle equipment loads have increased due to computers and communication equipment.

Comfort conditions for a single individual can vary depending on mood health, and activity. Between individuals it varies by age, sex and ethnicity and country of origin. HVAC design is for average comfort conditions. This can vary by country and culture. Maintaining the exact comfort conditions specified with systems, equipment and control systems can be futile and expensive.

Client provided information of internal loads of commercial buildings can result in under estimated cooling loads in commercial buildings. 99.6% ASHRAE winter design conditions can result in under estimated heating loads in commercial and residential buildings.

In the case of design programs that are used to size equipment, it is typical to apply a 5% safety factor for summer cooling in commercial buildings and up to 25% or more for winter heating in commercial and residential buildings. The Minneapolis winter design is -16F but it can down to -30F and below with high winds. Less than ideal conditions in summer for a few hours is not a problem. It is better than no conditioning. The efficiencies of cooling equipment (Chillers, fans, pumps, and heat exchangers) for part load conditions decline unlike direct heating.

Equipment Performance Accuracy

Air, water and heat transfer equipment performance in manufacturer's catalogs and computer programs are typically based on test data that are based on the specifications of AMCA (Air Movement & Control Association) and AHRI (Air-Conditioning Heating & Refrigeration Institute). Performance curves (based on engineering theory and physics) are generated from this statistical data and used in selection programs and tabulated catalogs. Equipment performance based solely on the properties of materials and physics & engineering theory is not considered reliable enough.

System and equipment performance declines as it ages. This includes all the equipment in ductwork and piping systems. Piping declines because of scaling on the inside surface. All equipment including plant equipment (boilers, chillers, cooling towers, domestic hot water heaters) has to be replaced. Regular maintenance is required but that does prevent declining performance. Ductwork, piping and equipment performance varies over time and estimating fan static pressure and pump pressure head have to take this into account.

Relative accuracy when comparing energy savings by envelope, systems and plant is important.

2. DOE21E ENERGY PROGRAM BY USDOE

DOE21E is a public domain program. DOE21E was extensively used by Architectural-Engineering Design firms (AEDs) from the early 1980s until early 2000s. It represented the energy program standard for the industry. The DOE2 program is still the standard since the most popular program today, eQUEST, is based on an upgrade of DOE21E – DOE22. Com-Check, based on DOE21E, is also still widely used.

The direct use of the DOE21E-BDL declined when forms and graphics interfaces became available, since 2000, for energy programs such as TRACE, HAP and DOE2. Although DOE21E-BDL can be used directly, this project’s success will still depend on privately developed forms and graphics interfaces such as Visual-DOE and Energy-Pro.

There is actually an advantage of having four independent program segments of Loads, Systems, Plants & Economics instead of putting the first three segments within one time loop. AEDs are more interested in practical use and results rather than extreme theoretical accuracy and it helps to check and correct the results of each segment before going to the next.

The accuracy gained by modeling Loads, Systems & Plants in one time loop is not significant to AEDs since the results of energy programs are not used in the design process and therefore does not affect construction and operation.

One of the reasons given for replacing DOE21E (and DOE22) with Energy-Plus was that the FORTRAN-77 code was outdated and badly organized & written by numerous programmers who have since moved on. The source codes of the major energy programs (TRNSYS, TRACE, ESP-r) originated in the 1970s also. eQUEST is based on DOE2 which is based on FORTRAN-77.

However 30 years of use has probably eliminated most of the bugs of these programs. In my opinion the DOE21E source code is therefore not obsolete unless there are errors in the analysis. The old code can be frozen and independent stand-alone new enhancements can be added by working with output from the old code subroutines.

Several private firms have developed easy to use forms and graphics interfaces to DOE21E. Energy- Plus is not an upgrade of DOE21E. If USDOE and LBNL were to abandon DOE21E, then these private firms will lose their investment.

The Building Description Language used to model the building in the input (*.inp) file could be improved with expanded keywords and expressions. The same applies to imbedding user created programming statements, functions and subroutines to perform specialized tasks required by projects.

The DOE2.2 Manuals offer a better explanation of adding user created expressions, functions and subroutines but there no examples.

The Loads segment of the energy program should be usable as a design loads program. This requires a "Space" level under the "Zone" level. TRACE presently has this feature and it can be used as a Loads program also. All spaces in the zone are controlled by a thermostat in one of the spaces and the temps in the other spaces are allowed to float.

The "hourly energy analysis" part of the DOE2 program should track these floating temps and determine the steady state temp condition of the spaces without the thermostat. The attachment includes a proposed form for space level input.

There should be an option to specify 2 or even 3 perimeter zones. The first would be a thermal zone for the envelope which could be as small as 6 inches depth to offset thermal transmission loads based on outdoor air temp and solar radiation on the outside surface. This zone conditioning maintains the inside surface temps of the envelope to eliminate the effect of radiant heating and cooling discomfort on people.

Residential buildings have perimeter heating systems at the floor level (heat rises) which maintains the temps of the inside surfaces of the envelope. Typically the perimeter system is heating only and cooling is by air supply in the interior.

In climates where outdoor temps exceed 120F with high solar radiation on the outside, the inside surface temps of inefficient glass cause discomfort due to the Mean Radiation Temp (MRT) effect if there is no perimeter cooling system. Presently DOE21E calculates the outside surface temps (can be viewed only in hourly reports) but not inside surface temps. The program should calculate MRT at two specified distances from the inside surface.

Day-lighting analysis should be able to estimate day-lighting levels separately for 0-15 feet and 15- 30 feet depths and there would be separate lighting dimming controls for each segment. Solar radiation would be applied to the first segment of 15 feet as before.

So there should be the option of being able to specify three types of perimeter zones. (1) for the envelope which deals with inside surface temps affected by transmission & solar radiation on the temperature of the outside surface, (2) a thermal perimeter zone of about 15 feet affected by solar radiation & interior loads and day-lighting, and (3) an additional day-lighting zone beyond 15 feet which would include interior loads.

It should be possible to specify at least two HVAC systems to serve spaces and zones. Example: WSHP, FCU, Baseboard, and other "non-air" perimeter systems, and a supply air or a dedicated outdoor air system (DOAS). The first takes care of temperatures and the second takes care of air flow - minimum supply air changes in medical facilities and ventilation requirements in all other facilities.

DOE2 program presently allows hotel rooms and apartments to have a "non-air" system (baseboard, fan-coil) in the space, but the outdoor air has to be supplied to the corridor and assumed transferred to the spaces through door undercuts.

It should be possible to specify more than one exhaust system. Example: Toilet Exhaust (TX), Kitchen Exhaust (KX), Laundry Exhaust (LX), and General Exhaust (GX) with separate schedules. As with "systems", spaces and zones would be assigned to the exhaust systems. Heat recovery between outdoor and exhaust air in hotels and apartments should be defined separately.

The Systems segment should include input forms for (1) Fans + Ductwork-Systems and (2) Pumps + Piping-Systems. See attachment. The information is obtained from running ductwork, piping and equipment selection programs and from manual design procedures. The Fan and Pump heads entered into the energy program forms would represent operation at peak design conditions determined by the Loads segment. Part load performance would be based on Fan and Pump laws.

Energy programs are now used for code compliance when submitting construction documents (CDs). It helps if information from the CD equipment schedules can be entered into the energy program to record how the final fan and pump heads were obtained.

DOE21E will require additional systems such as UFAD, run-around coil loop heat recovery, GSHP (the last two are available in JJH’s version 136 but not in LBNL's version 110), etc. If USDOE has joint ownership with JJH of DOE22, then a lot of its new features can be copied including PV.

A simple way of simulating UFAD would be to let the user specify separate space temp for up to 7 feet from floor level (say 75F) and another temp for the space from 7 feet to the ceiling (say 65F in winter and 85F in summer). For a 10 feet ceiling height it amounts to assuming an average space volume/mass temps of 72F in winter and 78F in summer. Actual UFAD performance is better.

Building design decisions are not made solely by comparing energy conservation measures (ECMs). First costs, maintenance labor and replacement parts costs and availability, ease of maintenance, reliability and durability of systems, and environmental impacts have to be considered. Final decisions are made based mainly on overall life-cycle costs, payback periods and return on investments. Life cycle cost analysis (LCCA) is required to compare ECMs.

Readily available and up to data cost estimating programs are therefore required to complement energy programs. They do not have to be the detailed itemized ordering and costing systems used by contractors. The cost estimating systems would be designed for comparing ECMs only and only relative accuracy and reliability are important.

Here is a summary of how to fix DOE21E so that it can be used for research:

- Expand the feature of inserting user created programming statements, functions and subroutines into the BDL so that engineers perform specialized tasks required by projects and insert them into the input BDL. Provide detailed documentation of how to do this with examples

- The intermediate results between Loads, Systems, Plants & Economics modules are saved in intermediate temporary files for use by the next module. Hourly results of all the FORTRAN variables from each module are available for print out by the program. The BDL input data is read into FORTRAN variables and so also are the output report variables. All this data should be organized, formatted and saved in Excel type files that can read by other programs.

- Freeze the existing code since it is error-free and make it possible for research students to add/attach independent sub programs to expand the features of DOE21E. The independent (or dependent) sub-programs that can be interfaced with DOE21E should include PVmodules, GSHP, UFAD, DOAS, Radiant-ceilings and other features not included in DOE21E. There could be multiple versions of each sub-program by different authors. A DOE21E committee should establish common output reports for them.

The DOE21E should be linked to the BLCC5 (Building Life Cycle Costs) program and a cost estimating program. The DOE21E and Com-Check programs should be linked so that the program can check for ASHRAE Std90 and Code compliance using information in the libraries.

DOE21E would be the core of a package of integrated programs which would include graphicsforms interfaces that can import CAD drawings, Com-Check, BLCC5, first + operating cost estimating, GSHP, PV, CFD, etc..

http://www1.eere.energy.gov/femp/information/download_blcc.html#blcc

http://www.energycodes.gov/comcheck/ez_download.stm

3. EQUEST AND DOE2.2 PROGRAM

It helps to also know how to use the DOE2 program directly when using the interfaces to the program such as eQUEST, VisualDOE and EnergyPro. It forces you to use the reference manuals that come with the DOE2 program and to understand the meaning and overall significance of each input item. You can avoid this when using interface programs such as eQUEST because of all the default values and design decisions are assumed by this program for different types of Buildings and also for different types of ZONES, Systems & Plants.

In the case of large projects the results of every zone and system has to be examined to make sure that there were no accidental input errors. If a zone result does not look right based on engineering experience, then the sub-components must be checked. If this does not produce a satisfactory answer then it is possible to examine the hourly values of a variable in the case of the DOE2 based programs.

eQUEST is good program. The following negative comments refer to eQUEST version 3.61.

The building has to be created with the wizard (Schematic-Design or Design-Development) in order to create the architectural model of building, floors and spaces. This is easily the best feature of eQUEST. Being able to trace AutoCAD drawings alone makes it the program of choice for AEDs. Some programs are able to import and use CAD and BIM models. Young engineers just out of college might get excited about this feature because they can show how clever they are. In practice it is ridiculous and a waste of time.

The program user should be allowed to enter the names of every component as shown on the construction drawings. This is the first thing that is expected when entering input directly into the DOE2.2 program (there are no default name assumptions).

It is difficult and tedious to recognize every layer, construction, schedule, zone and system name assumed by eQUEST for each building component (the data might be common to some or all them) and change them to the ones you see on the drawings. Some projects have over 1000 zones and nearly 100 systems. The project cannot be broken up into smaller pieces because it affects the demand cost and there is still only one plant. The user should have the option to be able to enter the names of the components when creating or adding them as with DOE2.2.

Except for plant and economics reports, it is difficult to check the other reports. eQUEST allows you to use your own names when you create building shell components and air side system types. However, the reports do not show these names.

The eQUEST program first assumes all the "design-criteria" the given building and component type and we have to check each form and cell to see what was assumed. Users that don't know any better are just going to accept it.

The program should show, the default, minimum and maximum values separately for the cell entry and the user should be able to enter the value. The old APEC HCC program did this. The user has to consciously make the input decision and not blame the program later. A document listing the defaults, minimum, maximum values (like the DOE21E BDL Summary document) and other assumptions will be helpful. The "Activity Areas Allocation" form should allow the creation of user named activity instead of having to use “Unknown”.

One of the best features is being able to trace AutoCAD drawings to create shells, floor plans, zones, and spaces and check that is done right by viewing it in 2D and 3D. It can only be done SD and DD. Entering the details and replacing all the eQUEST given names and assumptions to match the drawings, schedules and specifications have to be done Detailed Edit (DE).

I cannot see why more of the DE equipment, systems and plant input cannot be included in DD so that some projects can be completed entirely in DD. Obviously changing dimensional data with input forms cannot be done if the original model was created graphically. Being able to specify the output reports in DD should be a priority.

The spreadsheets are convenient for this. You cannot go back to DD from DE without losing all the information created in DE. During the design process the architectural plans change frequently. You cannot make these changes without starting all over again.

I tried creating DOE2.1E and eQUEST models of a 50 zone project but because of the numerous default values and assumptions made by eQUEST (even with building type = Unknown) and the difficulty of fixing every design criteria value and schedule to match client specifications, it is difficult to get the results of DOE2.1E and eQUEST to match.

It took about a day to create DOE21E model using my own component names a data. It took a couple of hours to create the architectural model and enters Loads data. It took several days to edit the same model by changing the eQUEST names and defaults to match the names and values in the construction drawings, schedules and specifications. See project "High-Rise-Bldg"

In the case of such large projects with 100 or more zones, it helps to first create Master (or Global as in TRACE) and Project (created by editing a copy of Master) data for different types of Buildings, Zones, Systems & Plants, first and then creating each component such as Zone by assigning and editing a project component. This can be done with most programs such as TRACE and even the APEC MEP programs that were first developed in the 1960s.

In the case of DOE2.1E the Master, Project and Component override can done with design criteria assignments under PARAMETER, then with commands and keywords such SPACE-CONDITIONS, SETDEFAULT- FOR, ZONE- (CONTROL, AIR, FANS), SYSTEM- (CONTROL, AIR,-FANS, TERMINAL, FLUID, EQUIPMENT), PLANT- (PARAMETERS), etc, .

The Min-Max range and Default is published in the DOE21E manuals and BDL Summary. It can be done in DOE22 and used as templates (libraries) that can be copied into other projects. This is not possible with eQUEST.

The comment statements inserted into DOE22 disappear when it is read by eQUEST. One of the advantages of the BDL of the DOE2 and Energy-Plus programs is that it can be read as design and modeling specifications (with comments) unlike the information that is scattered in different input forms. There are advantages to using the BDL directly without input forms or using the two methods together. The eQUEST interfaces should retain the comment statements inserted in the BDL or INP file.

I have tried doing this with DOE22, but when it is read by eQUEST, the utility rates, schedules and constructions are broken up into their components and grouped separately.

DOE2.2 already has a more advanced system compared to DOE21E (and it is better documented in volume 3) and perhaps it can be copied into DOE21E. Direct input into the INP file has several advantages over entering data using forms.

4. ENERGY-PLUS PROGRAM BY USDOE

My familiarity with this program is as of 2005 and is limited. The comments below could be questionable and erroneous.

The execution time needs to be reduced. The latest 2010 release claims to done this.

There is an option to choose between time intervals from 60 minutes to 10 minutes (I think). AEDs are going to choose the simpler 1-hour intervals. Weather data comes in 1-hour intervals and weather does not repeat itself from one year to the next. Schedules of interior loads are in 1-hour intervals and they are very approximate. Occupancy schedules are based on guesstimates. Two identical office buildings next to each other will not have the same occupancy in any given minute.

15-minute time intervals might have some significance in power demand measurement since utility demand rates are based on 15-minute intervals and not the average of 60 minutes. This would result in an error with programs that use 1-hour intervals.

As with time-intervals, extreme theoretical accuracy is not an issue. Schematic Design (SD), Design Development (DD) and Construction Documents (CD) phases are based on design and equipment selection programs and the results of energy programs are not used again during design.

There should be an option to choose between the heat balance method (which adds to the execution time) and the transfer function method used by DOE21E. Energy programs are used by AEDs to compare alternatives such as baseline and proposed. The greater accuracy of the heat balance method becomes insignificant when added to the internal loads of commercial nonresidential buildings. Internal loads are the biggest energy component of such buildings and their associated hourly schedules are very approximate.

Modeling Systems & Plant with a single combined network of ductwork and piping sections using node numbers, branches, fittings, etc. in an Energy program does not make the program more accurate. Design Piping and Ductwork design programs are offered separately and there is no simultaneous design because in practice it is done separately. Even now most engineers prefer to design ductwork and piping systems manually with "ductulators" and "pipulators", or sizing charts.

The performance of ductwork, piping, coils, terminals, and other equipment in ductwork & piping systems decline with age. Scale builds up in piping and coils, filters and other equipment have to be cleaned frequently to maintain design conditions. The systems nodal network analysis in Energy Plus does not make the program more accurate.

There should be an option in the Systems segment to specify complete air (ducts) and fluid/liquid (pipes) system packages with their equipment as one input system with associated parameters similar to DOE21E, TRACE, etc. Ductwork and piping design with equipment occurs throughout the design process. Energy programs are used during the Schematic Design (SD) phase when this information is not available. Describing ductwork and piping networks in detail with associated equipment in an energy program is deterrent to the use of the program.

Energy-Plus can now build a dozen HVAC templates for easy input of typical systems – fan coil, VAV, PTAC, PTHP, WSHP, PVAV, etc. However, these template inputs then get converted into full inputs for E+ which includes nodes, branches, list, loops, etc., which adds to the execution time. Performance of each component of the network (piping, ductwork, coils, fans, etc.) should be entered with input forms information from the CDs. See attachment for fan and pump analysis forms.

Energy programs are now expected to show energy code compliance when submitting their construction documents (CD). AEDs cannot justify the additional time and cost to recreate ductwork & piping networks for each system with equipment and enter other detailed information again into an energy program at the CD submission stage of the project.

Energy programs are used to compare energy conservation measures (ECMs) and for estimating the building energy use. Measurement & Verification (M&V) of energy use in completed commercial non-residential building projects tend to show that computer predictions tend to be lower than actual energy use. Extreme theoretical accuracy cannot claim to produce superior and more accurate results compared to the results from the DOE2 program.

The features of Energy-Plus described above are mainly of interest to academia and research institutions. Such a program is useful and important in studying the performance of specific components. AEDs are going to continue using DOE2 based programs such as eQUEST (or TRACE and HAP) until there is a version of the Energy-Plus that is easier to understand, learn-to-use, and to use. The Energy-Plus execution time is such that the user will have to work on other tasks while the program finishes running. This is an inconvenience that AEDs will avoid.

Energy-Plus has added some significant modeling features that DOE-2 did not have, e.g. natural ventilation, radiant cooling and heating, UFAD, thermal displacement ventilation, day-lighting and controls, thermal comfort, water usage, PVT, and renewable power.

These features are important to the AED process and the barriers that prevent AEDs from using the Energy-Plus program should be removed and they should or be added to the DOE21E program so that private firms that invested in interfaces to DOE21E can benefit from it.

Even if Energy-Plus is fixed to become significantly easier, faster and less expensive (in personnel time) to use compared to the currently used programs in the US (eQUEST, TRACE and HAP), it would now have to overcome the inertia and apathy of users to make them switch from the programs that they have mastered.

The privately developed interface to the Energy-Plus program will have to compete with the free eQUEST interface to DOE2.2 and they would have to compete with the stability and reputation of the companies offering TRACE and HAP.

DOE21E should therefore still be supported, maintained and enhanced by USDOE and LBNL until AEDs accept Energy-Plus as the replacement program for DOE21E.

5. TRANE'S TRACE AND CARRIER'S HAP ENERGY PROGRAMS

REFERENCES

1 - Contrasting the capabilities of building energy performance simulation programs by Crawley, Drury B. and Hand, Jon W. and Kummert, Michael and Griffith, Brent T. (2008).

http://dx.doi.org/10.1016/j.buildenv.2006.10.027

2 - DOE2 by Lawrence Berkeley National Laboratory (LBNL) and US Department Of Energy (USDOE).

http://gundog.lbl.gov/

3 - eQUEST by J.J. Hirsch and Associates. http://www.doe2.com/

4 - EnergyPlus by University of Illinois at Urbana-Champaign (UIUC), by Lawrence Berkeley National Laboratory (LBNL) and US Department Of Energy (USDOE). http://gundog.lbl.gov/

5 - TRACE by Trane Co.. http://www.trane.com/Commercial/DNA/View.aspx?i=1136

6 - HAP by Carrier Corp..

http://www.commercial.carrier.com/commercial/hvac/general/0,,CLI1_DIV12_ETI11936,00.html

7 - TRNSYS by University of Wisconsin at Madison. http://sel.me.wisc.edu/trnsys/

8 - IES-VE by Integrated Environmental Solutions. http://www.iesve.com/NAmerica/

9 - ESP-r by Strathclyde University. http://www.esru.strath.ac.uk/Programs/ESP-r_overview.htm

CASE STUDIES WORK PLAN EXAMPLES - Office, Hotel, Multi-Use, School, Campus

Case Studies - Envelope, Systems, Plant Options - LCCA Rating

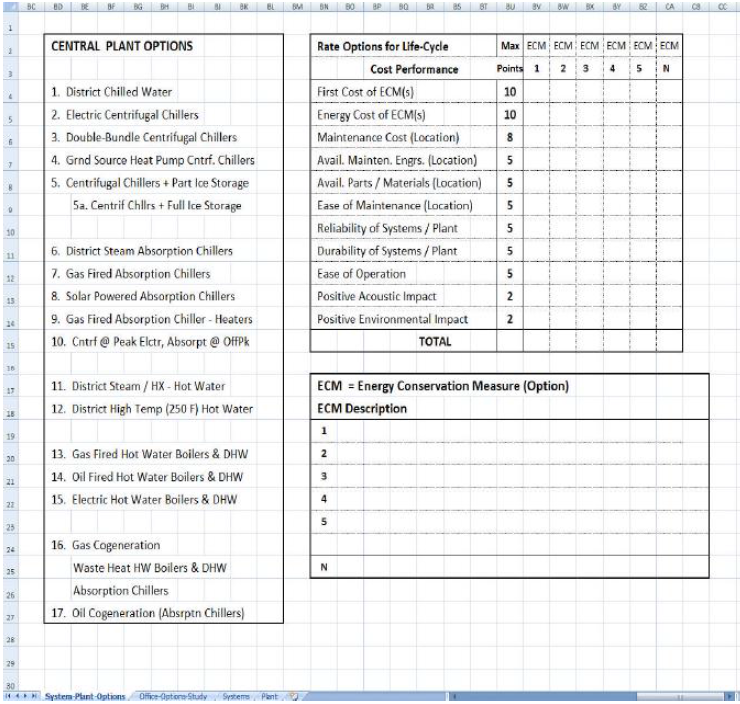

Figure - 1 C1 Case Studies - HVAC Systems Options

Figure - 2 C2 Envelope and Plant Options

Figure - 3 C3 Central Plant and ECM Rating

C3 Building Type Database Library - Design Criteria and Specifications

EXAMPLE - HOTEL

Figure - H1 Hotel Bldg Plan 1

Figure - H2 Hotel Bldg Plan 2

Figure - H3 Hotel Bldg Plan 3

EXAMPLE - HIGH-RISE MULTI-USE Building

Figure - High-Rise Mixed-Use Bldg

EXAMPLE - MIDDLE-SCHOOL and COMMUNITY-CENTER

Figure - Middle-School + Community-Center 1 - Floor-Spaces

EXAMPLE - OFFICE-Floors Irregular-Sides + Atrium

EXAMPLE - COLLEGE CAMPUS

Energy Efficient Campus Study