Building Production Efficiency Using Industrial Management Methods

1994 Project Proposal - by Varkie C. Thomas, Ph.D., P.E.

INTRODUCTION

Industrial Engineering Management is a branch of engineering management dealing with the optimization of complex processes or systems. It is concerned with the development, improvement, implementation and evaluation of integrated systems of people, money, knowledge, information, equipment, energy, materials, analysis and synthesis, together with the principles and methods of engineering design to specify, predict, and evaluate the results to be obtained from such systems or processes.

In the manufacturing industry the cost of products decreases with time, despite inflation. It starts with the design of the product. In contrast, the cost of designing and constructing a building increase each year. The proposal looks at industrial engineering management methods that can be applied to building design and construction. It requires a single pre-defined management model of integrated processes of tasks, financing, information, equipment, materials for design and construction. The model has to be defined at the beginning of each building project.

In 1992 the Society for Computer Integrated Building Sciences (SCIBS) was established to create such management models for different types of buildings. Officers included:

| President | David Childs, President, Skidmore, Owings & Merrill |

| Vice-President | John F. Hennessy III, Chairman/CEO, Syska & Hennessy |

| Treasurer | Donald L.Wickens, President/CEO, Benham Group |

| Support | Donald E. Ross, Managing Partner, Jaros, Baum & Bolles Joe Buskuhl, President, HKS Architects Louis Shaffer, Director, CERL, U.S. Army Corps of Engineers David Hudson, Vice-President, RTKL & Assoc. Reginald Boudinot, Vice-President, Booz-Allen & Hamilton Michael Griebel, Vice-President, Henningson, Durham & Richardson Craig Martin, Vice-President, CRSS Inc. Kenneth Herold, Corporate Director, Hellmuth, Obata & Kassabaum Mark Bailey, Manager Building Technologies, USDOE Earle Kennett, Vice-President, NIBS (NIST) Steve Selkowitz, Head of Building Technologies, LBNL Gideon Shavit, Director, Advanced Systems at Honeywell Tom Mikulina, Vice-President, Trane Company Jim Hope, Technical Director, ITT Fluid Handling Division Dennis Miller, Manager, Johnson Controls Research |

SCIBS closed down in 1994..

1. PROJECT SUMMARY

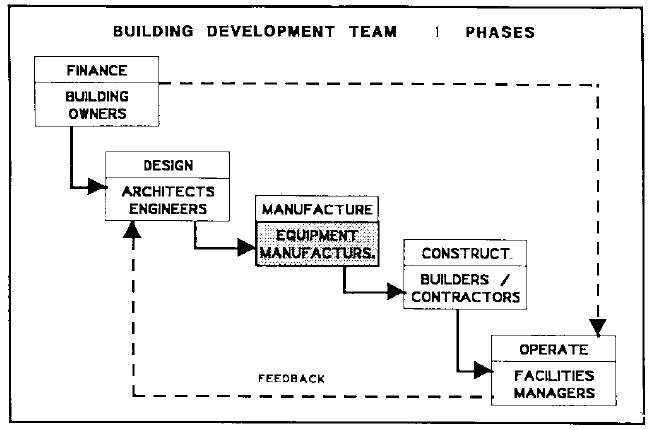

This project will study the life-cycle of large and complex buildings. The long term objective is to re-structure the building development and operation processes and the fragmented organizational structure of the building project team, in order to make the best use of new and constantly changing supporting technologies in automation and telecommunications.

The project will treat buildings as manufactured product a unit using industrial engineering methods when determining the ideal organizational structures, development processes and management responsibilities required to produce the units efficiently. This project will recognize the building life-cycle process as an integrated macro science.

Because of the scope, size and complexity of such a venture, this project will emphasize mechanical and related electrical (M-E) design systems as integrated and interactive components of the Architectural - Engineering (A-E) design phase and then track the M-E design system through the remaining phases of the building life-cycle.

The scope of this project will include a study of

(1) the creation, structure, management, coordination and communication of information during the building life-cycle;

(2) inter-professional and inter-organizational responsibilities and interaction during the development and operation of different types of buildings;

(3) the integrity of the original building model created by the A-E design team through the remaining phases of the life-cycle process which include equipment (selection and installation), construction and operation;

(4) information feedback from operation (facilities engineering, facilities management and building automation systems) to the A-E design team;

(5) the application of industrial engineering, quality control and cost control methods used in manufacturing (volume batch production) to the design and construction of buildings;

(6) the application of innovative automated design and construction methods being developed currently.

The main products resulting from this research will be educational materials that use case studies of building projects that present a holistic, inter-professional, inter-disciplinary, object-oriented approach to the building sciences. Deliverable products will consist of:

(1) documentation of the M-E systems component of the communication and coordination life-cycle process model for different types and sizes of building projects;

(2) educational materials for universities that show M-E design as integrated system and as part of an interdisciplinary and interactive process of A-E design - the way it occurs in practice.

2. VISION AND RATIONALE

During an interview on CSPAN TV, Dr. Milton Friedman, the Nobel Laureate in Economics at the University of Chicago was asked to explain his new book's cover which showed him holding a pencil in front of him. The following was Dr. Friedman's explanation (slightly modified):

The lead for the pencil was mined in South America. The lead industry organizations and operations on the South American continent were involved in the production and cost of the pencil. The wood for the pencil came from the timber industry in North America. The eraser for the pencil came from the rubber industry in the Asian continent. The metal that holds the eraser and pencil together came from the African continent. The pencil was manufactured in Europe and distributed to all parts of the world. The cost of each pencil is 5 cents. How is this possible?

In the manufacturing industry automobiles come off the assembly line and are delivered to customers all over the world at about $15,000 per unit with preset (such as 95%) product reliability. Individuals working on the manufacturing process can be changed but the process is fixed and does not change. Transportation, communication, industrial engineering, automation, robotics, and quality control engineering and management models that are precisely defined and recorded (on paper so that it can be studied and continuously improved) enable this to happen.

In the case of large and complex buildings there does exist some sort of standardized procedural models of segments of the total building process, that are recorded in the heads of professionally specialized senior project engineers and managers and improved continuously within their heads through their experience on projects. These fragmented procedural models and information systems cannot be read, studied and improved by research teams. The pieces are brought together and coordinated uniquely for each building project through a continuous process of coordination meetings. Pieces of the total process change when individuals on the project team change.

A PBS TV program entitled "Skyscraper" trying to describe the building development process taped some of the project coordination meetings at Skidmore, Owings & Merrill (SOM). It showed how decisions (that appear to be made informally and instantly) at these meetings start a chain reaction of manufacturing, shipping and other processes around the world since the cost of waiting for all design plans to be completed is high ("fast track" construction is now common).

Building production is not standardized and documented process. The process (along with project plans and schedules) are determined independently for each project, during the project, revised continuously during the project and they are reinvented for future projects. Unlike manufacturing, there is no pre-determined, precise, "canned" methods to produce buildings as whole and in volume. The buildings need not be identical but they have to be of the same type as say high-rise offices.

Consider the 3.5 billion-dollar, 12 million square foot Canary Wharf building project in London, United Kingdom. Conceptual master plans began at SOM-Chicago in the mid 1980's. This project, involving thousands of professionals and hundreds of organizations from around the world, was completed in the mid 1990's. Each professional and organization knew their own specialized role through experience, and how they would interact and work with other professionals and organizations within their own sphere of related activities only.

This informal, non-standardized and largely unrecorded coordination and communication working infrastructure for developing large and complex buildings evolved over several decades and was made increasingly reliable and efficient in the US. This was the technology that enabled the US to dominate the design and construction of large and complex buildings until the 1990's. The technology to put the whole building life-cycle jigsaw puzzle together through an undefined and unrecorded automatic chain reaction begins with the architectural design firm and goes down several professions and organizations until the project is completed.

The technology of communication and coordination of information took a big leap forward in the 1990's with the advances in automation (computer hardware, software and telecommunication) technologies. It is now possible for architects and engineers scattered around the country (or around the world) to work on the same project simultaneously as if they were next to each other using the same computer hardware.

Segmented engineering processes (computation and design) are becoming software "black boxes" with an input and an output and they are continuously increasing in scope and power. Understanding, defining and standardizing the building development process, automating the process and applying industrial engineering techniques to improve the process, will bring the efficiency and reliability of the construction industry closer to that of the manufacturing industry.

The long-term objective of this project is to study the building development process as a whole with an emphasis on how pieces of architectural-engineering information come together through professional and organizational interaction at coordination meetings.

Information about this science is only accessible to professionals on the project and the AEC firms that employ them, cannot justify the cost of making a dedicated effort to record, study and improve the total process. Research/academic institutions must work with building project teams in documenting, studying and improving the process.

The application of the automation technologies (artificial intelligence, expert systems, etc.) that are being developed by research groups to the building process must be applied, tested and evaluated on actual building projects.

3. PROJECT JUSTIFICATION

Problem: The Building Industry - Organizational Structure and Professional Specialization

Today's well-established technical and business organizational structure in the building industry is based on a long history of development and operation without computers. Architectural-Engineering (A-E) software development continues to cater to this old structure and tend to imitate the manual, pre-computer building processes. Automation is being tailored to fit a building communication process and an organizational structure that evolved over centuries and was designed for the non-automated production of buildings.

With today's computer hardware, software, and telecommunication technology, it is possible to develop a specialized program module that can operate as an integral component of a larger building development and operating system. This requires standardization of the of the information exchange interfaces.

Professional specialization, organizational responsibilities, and project development procedures must adapt to these continuous technological changes. Object oriented software applications that cross traditional professional barriers and organizational responsibilities are generally considered the most efficient solutions for developing information based building systems.

To produce the building unit efficiently, the building must be treated as a product unit first and the ideal organizational structure, professional specialization and development processes must be determined.

Problem: Communication and Coordination in the Building Industry

The basis for developing efficiently integrated and automated building systems within a fragmented building industry, is the science of inter-professional and inter-organizational communication and project coordination. Presently, the communication system for developing and operating buildings varies not only with locations, types of buildings and economic factors, but also with the background experiences of the specialized professionals on the project team.

The senior level technical staff of the various types of specialized firms working on large and complex buildings spend a significant amount of their time at project coordination meetings where most of the information exchange and integration processes occur today. There are no formalized procedures or guidelines for these meetings or for information recording and retention. Most errors, cost overruns, and liability claims can be attributed to failures in communication and coordination.

Organizing and classifying building products and systems from an object oriented perspective and defining data exchange interfaces for automated systems serving the industry, have to start by recording and studying existing communication and coordination procedures, and then change to more efficient methods through research, educational programs and literature. However the existing communication and coordination procedures have never been officially defined or documented by the building industry.

Information on completed building projects is not available to research centers although it now exists on computer disks and tapes. Access to information on live and completed building projects is difficult except for the active participants on the project. Client confidentiality and liability fears also restrict access to project information. Industry cannot justify the time and expense of studying and documenting this science.

Although individuals from the various professions communicate with each other and coordinate their efforts in developing a building, the professional societies and institutes that they belong to are fragmented by disciplines, and these groups rarely meet or communicate with each other. Research centers and academics tend to be isolated from the actual building process.

Theoretical solutions developed by research centers without the participation and support of industry, tend to ignore today's organizational structures, professional specialization's and project development procedures that evolved over decades. Such solutions cannot be implemented within a fragmented building industry.

Technical decisions related to completed building projects can be found in

(1) the drawings and specifications issued by A-E design firms,

(2) shop drawings issued by product vendors,

(3) construction plans of contractors, and

(4) performance output from building automation and control systems.

The sequence and inter-professional interaction that produces these decisions have not been studied or documented. The present industry procedure is to transfer drawings, specifications and other documents into storage archives at the completion of a project. This information is eventually destroyed or lost. A mechanism to provide this information to research centers must be developed.

Architectural, engineering, and construction theory and methods can be taught and learned because they have been documented. The communication, coordination and decision making processes involving several types of professionals and organizations that produces a building, have to be learned on the project from more experienced professionals within fragmented and specialized project segments. This science represents the glue that holds the building process together and makes the building project happen.

This knowledge presently resides in the form of experience (and the nature of this experience varies with each individual) in the minds of several types of professionals working in different types of specialized firms serving the building industry. In the case of large and complex buildings, several types of professions working in several different types of organizations are assembled together to form the project team. The project team, including product suppliers, are rarely repeated from one building project to another.

The science of communication and coordination within a fragmented building industry is presently re-invented for each building project and continuously modified during the project.

Opportunity: Communication and Coordination Models for the Building Industry

This project will contribute to the development of a master plan and specifications for a global electronic information communication and sharing network model for the building industry. Such an information model to promote inter-operable software applications for the building industry is presently being developed by the Industry Alliance for Interoperability (IAI).

This project will work with IAI and other organizations and research efforts dedicated to integrating and automating the total building life-cycle process. It will provide some of the background information needed for developing data exchange standards and guidelines required by an information model for the building industry.

An information model for the building industry must

(1) be developed with the support of industry using consensus procedures in order to ensure that it will be accepted and implemented by industry,

(2) identify the locations of building project development and operating processes and phases within the total building system, and

(3) encourage and facilitate the direct exchange of information between specialized, independent and proprietary software systems serving the various professions and segments of the industry.

The proposed research project involves participation by the commercial segment of the building industry in developing the science of inter-professional and inter-organizational information communication and building project coordination that use state-of-the art automation and telecommunication technologies.

Research material necessary to study the science of information flow through the building life-cycle process is imbedded within the building industry but not explicitly defined or accessible. It is also fragmented and scattered throughout the industry.

The project will collaborate with several nationally recognized research centers in developing this science. The scope of developing a national and international building life-cycle information model requires several organizations. The number of alternative solutions can be numerous.

The development of this science will enable the U.S. building industry (particularly A-E design firms that are labor intensive) to be competitive in the international market where labor costs are considerably less.

Opportunity: Building Design and Construction as an Industrial Engineering Process

The rationale for proposing the application of industrial engineering (IE), quality control and cost control methods used in the mass production (manufacture) of a product, to the building and construction industries is based on

(1) the use of predefined life-cycle communication and coordination process models (information highway maps) of different types of buildings,

(2) the use of nationally standardized building information databases accessible through computer networks,

(3) the realignment of organizational structures and professional responsibilities to make the optimum use of standardized communication and information systems and networks, and

(4) building life-cycle costing to measure the reliability and efficiency of the building process.

A comparison of cost trends in the building industry and the manufacturing industry indicates a growing gap between them. In the manufacturing industry, product costs decrease with time, while their reliability and technical quality tend to improve during the same period. In the building industry, the cost of a building as a unit product increases with time and, as its technical complexity increases, so also do the number of liability claims.

Another dissimilarity between the two industries is that the group that develops and markets a manufactured product tends to be different from the group that uses the product. In the building industry, the developer and owner of commercial, industrial, institutional and health care buildings can be the same. The term life-cycle cost is associated mainly with buildings. This would suggest that the natural momentum would be to drive down the cost of buildings using new technology, and to increase their reliability. This has not been the case.

The question then is can the building industry become as efficient and reliable as the manufacturing industry, even though non-residential buildings are not mass produced ? Given today's (and the ongoing progress in) automation and telecommunication technologies, industrial engineering sciences can be applied to building design and construction that will produce efficiencies comparable to that of the manufacturing industry, without compromising the uniqueness of each building.

The solution is to redefine the organizational structure of the building industry to make the optimum use of automation and telecommunication technology, and to define and automate the flow and exchange of information during the building life-cycle.

The economies of mass production, and quality control methods associated with industrial engineering, can be applied by a building project team to produce unique building units.

Opportunity: Recognizing the Building Life-Cycle Process as a Macro Science

A holistic and professionally integrated approach to the building life-cycle process is presently not a science that is officially recognized by the building industry and it is not taught at educational institutions. One possible explanation for the present status is that there is no single professional group that serves the building industry as a whole.

The building science has been broken up into several pieces based on manual procedures of the past, and distributed among several types of professional societies and institutes. This science can be formalized, documented and taught, and the communication processes can be automated in the future. The barriers to achieving an automated and integrated building life-cycle procedures are administrative and political, and not technological.

Developing a meaningful and acceptable national and international (most large building projects today involve multi-national project teams) information system for the building industry requires a technical effort and commitment from the building industry as a whole. A fragmented building industry has to be persuaded through external incentives to change organizational structures and procedures that were established over a long period of time and adapt to new technologies.

The transition process must begin with educational institutions and educational literature. The emphasis of this project will therefore be on documentation and education to improve and maintain the efficiency of the building life-cycle process.

Recognition, development and application of this science will produce efficiencies and costs that come closer to the manufacturing industry. This project will initiate and recognize a science that will be on-going.

Opportunity: Industry Participation in Developing the Project

This project is significant because industry will participate in developing a science that is imbedded in industry but not explicitly defined or accessible. The science is also fragmented and scattered throughout the industry. This science can be recorded, studied and improved. Industry will benefit from this project through efficiently coordinated and integrated building development procedures, lower first and life-cycle costs, and fewer errors and liability claims.

Academia will benefit from educational materials that are based on actual building projects and state of the art technology with mechanisms for updating the educational materials with the ongoing progress in industry and research centers. This project will establish a partnership between industry and academia to develop this science.

This project will improve the efficiency, reliability and predictability of the building lifecycle process.

4. SCOPE

The task of developing a global information model for the building industry is extremely large and complex. The scope of this project is therefore limited to defining and documenting the life-cycle information flow process of mechanical and related electrical (M-E) systems for buildings with an emphasis on M-E design as an integral interactive process within the architectural-engineering (A-E) design process.

The project does not involve software development directly but it will provide the model for developing an integrated, interactive and inter-disciplinary automated system for the building life-cycle process. The project will emphasize industry problems and requirements, and industry acceptance and implementation of the results.

The scope of M-E systems includes Heating, Ventilating, Air Conditioning, Refrigeration (HVACR), Plumbing, Fire Protection, Automatic Controls, Energy, Lighting, and Electrical Power. In the case of large and complex buildings (commercial, industrial, institutional, and health care), the first cost of M-E systems component can be more than a third of the total building cost, and the 25-year life cycle cost of mechanical systems can exceed two thirds of the total cost.

A recent study funded by the National Science Foundation (NSF No. CES 8719788, 1991) indicated that mechanical systems (and electrical - electronic systems associated with of mechanical systems) were the leading cause of performance failures that had to be resolved through litigation.

The M-E information system will be developed with the support of other professional groups (architects, structural engineers, facilities managers, etc.), who will be responsible for initiating and implementing parallel and complementary components of the complete building information system.

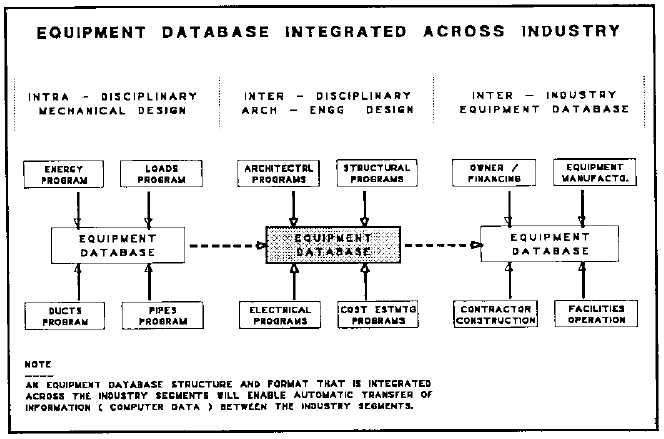

The information flow study will consider the seamless transfer of information from the building design process to the order-entry, transportation and numerical control systems of product suppliers, the construction management programs of contractors, and the facilities engineering programs of building automation/controls companies.

Initial versions of the system will be based on existing professional and organizational boundaries in the industry. Later versions of the information system will propose the most efficient solutions from an automation and communication perspective, that are independent of professional and organizational barriers set in the past.

The project will study "building systems integration and automation" work by industry, universities and research centers It will work with such groups in evaluating their ideas and solutions, and incorporate them into the building information system. It will collaborate with the Industry Alliance for Interoperability and with groups working on "ISO/PDES/STEP" standards, including the Computer Integrated Construction Group at the National Institute of Standards & Technology (NIST), US Department of Commerce. It will collaborate with the COMBINE (Computer Models for the Building Industry in Europe) group which is a consortium of research centers and industry in Europe working towards similar objectives as this proposed project.

It will investigate the application of the "Integrated Product and Process Development (IPPD)" technology developed at the Construction Engineering Research Laboratories, U.S. Army Corps of Engineers (CERL/USACE), to the building life-cycle information process. It will incorporate into the M-E system "Energy Design Tool for the Initial, Schematic Phases of Building Design", "Building Design Advisor", and "Power DOE" systems developed at Lawrence Berkeley Laboratory (LBL).

5. OBJECTIVES

Organization

Describe present organizational alignments (varies for different types and sizes of projects) and professional and organizational responsibilities for creating, managing and modifying project information.

Describe inter-professional (inter- disciplinary) and inter-organizational communication and project coordination processes that occur during the development of buildings. This is accomplished today mainly through meetings, exchange of drawings and other manual procedures.

Identify the major building products (generally accepted in the industry as stand-alone components) and systems with their attributes. Describe the relationships and dependencies between the products and systems.

Communication

Develop building information flow process models that maintain the integrity of the original design model created by the architectural-engineering (A-E) design team, through the remaining phases (manufacturing, construction and operation) of the building life-cycle process, instead of redeveloping the model at each phase.

Develop procedures for transferring information from operation / facilities engineering processes (building automation systems) back to the architectural-engineering design team, so as to continuously and automatically improve the efficiency of the building life-cycle process.The information flow process in the building industry presently has no feed back from the operating phase back to the design phase.

Demonstrate the flow of information through the integrated building life-cycle model using case studies (a variety of building projects modified to eliminate repetition and detail). The case studies would try and follow the inter-disciplinary sequential steps used in designing, developing and operating large building projects.

Investigate the legal aspects of communication and information transfer associated with international projects using multi-national project teams and the legal aspects of direct electronic information transfer.

Work with national and international research centers in developing specifications for an electronic information communication system (highway map) for the building industry.

Process

Develop an integrated inter-professional (inter-disciplinary) object and systems oriented approach to the building life-cycle process (design, construction and operation of buildings).

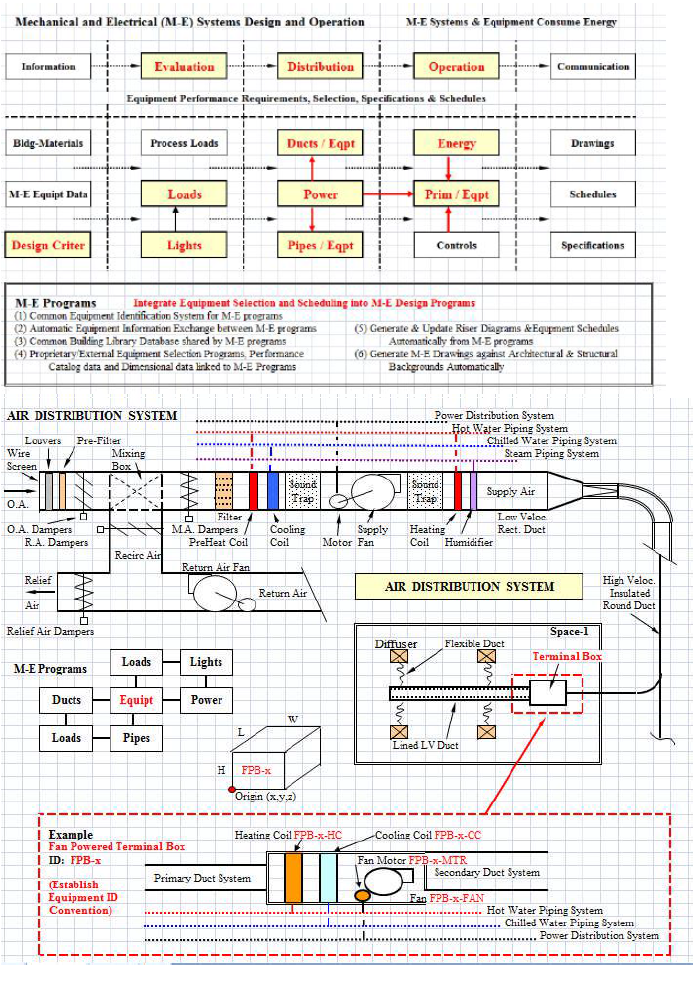

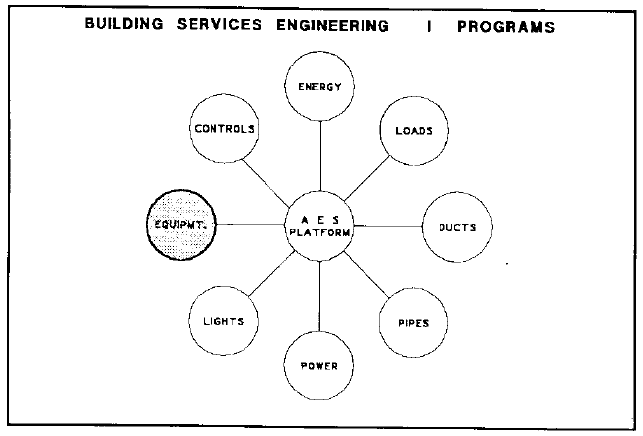

Describe the theory and calculation procedures of M-E systems design using the organizational logic of computer programs and as part of an integrated and interactive building life-cycle model.

Develop preliminary design and criteria based design procedures (when detailed information about a proposed building is not available) by developing and using nationally maintained historical databases of completed building projects, and information libraries for codes, standards and design rules for different types of buildings under different conditions such as locations, budget constraints and economic situations.

Investigate the application of manufacturing (industrial / production engineering) technology to building design and construction by using organizational structures designed for the production of buildings as a complete unit, and by using predefined information communication flow/exchange models and networks for different types and sizes of buildings in different locations.

Education

Develop educational materials that present a holistic, inter-professional and interdisciplinary object-oriented project approach to the building sciences instead of the separate and independent topic presentation formats used within each specialized professional group.

Develop educational materials that teach architectural and engineering students (and also junior architects and engineers in practice) how to interact with each other and work as a team - the way it occurs in practice.

Develop educational textbooks that teach the architectural engineering sciences based on the previous two objectives.

6. EDUCATIONAL PROGRAMS AND PRODUCTS

Recognizing the science of communication, coordination and integration during the building life-cycle process must begin at educational institutions. Isolating this science to emphasize its importance is necessary. However the science is imbedded and scattered throughout the AEC industry.

The process has to be studied on "live" and "completed" building projects at AEC firms and documented by academic institutions. AEC firms that will be actively involved with this project with design and product information include Skidmore, Owings & Merrill, IBM Corp., Sweets Electronic Publishing (McGraw-Hill), ITT Bell & Gossett and Trane. AEC industry participation will be expanded during the course of the project.

Educational materials will be developed that present a holistic, inter-professional / disciplinary and inter-organizational approach to the building sciences. The educational literature will identify, classify and organize building products and systems as integral components of an architectural-engineering design model, and then track the components through the manufacturing, construction and operating phases.

The emphasis will be on the creation, structure, flow, and communication of information and professional and organizational responsibilities for the information. The publications will initially draw on the technical literature of the supporting AEC firms that are part of the primary project development team..

7. EDUCATIONAL MATERIALS

The project will develop educational materials that cover some of the following topics (shown below) that would constitute a Masters Degree Program in Building Services Engineering (M-E systems). The topics would be integrated through project case studies that apply theory to practice.

| A. Loads, Systems, Equipment Analysis | B. Energy & Life-Cycle Cost Analysis |

| C. Plumbing / Water & Waste Treatment | D. Fire Protection and Life Safety, Codes |

| E. Air Handling & Distribution Systems | F. Liquid & Gas Distribution Systems |

| G. Building Automation Systems, Controls | H. Noise & Vibration Control |

| I. Electrical Power Distribution Systems | J. Telecommunication & Security Systems |

| K. Building Transportation Systems | L. Illumination (Lighting) Engineering |

| M. Construction and Commissioning | N. Facilities Engineering & Management |

| O. Project & Construction Management Economics | P. Building Finance & Engineering |

8. PRELIMINARY LIST OF AREAS FOR STUDY AND DOCUMENTATION

1. Information types, sources, structures, networks and access. One category will consist of information from the handbooks of professional societies and institutes, and from building design, construction and operation codes, standards and guidelines. A second category will consist of proprietary performance data of products by manufacturers of various types of equipment and systems. A third category will consist of historical information on completed building projects. The objective here is to agree on structure (and not on reproducing the data) so that the information can be accessed on information (highway) networks by proprietary modular software systems.

2. The integrated approach to mechanical and electrical systems design. This segment will be organized on the basis of similar processes. It will follow the interactive sequence of designing buildings and it will parallel the logic of computer software. Since engineering theory is already described and explained in the literature of professional associations, institutes and societies, the purpose of this segment is to identify and organize the "engineering theory modules (subroutines or functions)" so that they can be incorporated into the building lifecycle information flow/exchange model.

3. The architectural-engineering (A-E) design process. This segment will follow the sequence of developing buildings at A-E design firms. Besides final design that generates construction documents, this project will develop a method for preliminary and criteria-based design and cost estimating using information libraries when detailed information about the project is still not available. The validity of preliminary design and costs will increase with the expansion of the libraries.

4. Professional and organizational structure of the building project team. This will include the results of a study of present structures (varies considerably) and optimum structures for different types of buildings and conditions that will utilize automation and telecommunication technologies efficiently. It will include the results of the legal aspects of direct electronic information transfer using multi-national project teams on large international building projects. The information exchange procedures used by a fragmented building project team will be documented. This will include the flow of information from A-E design through construction and operation.

5. Project execution plans for developing different types and sizes of buildings. Presently this industry comes up with a new plan for each new building and these plans depend on the background and experience of the project managers involved. Master plans similar to master specifications will improve the efficiency of the building process and reduce communication errors and liability claims.

6. Case studies. The case studies will include office buildings, hotels, shopping malls, and hospitals. The design phase will be emphasized. They will demonstrate the application of the information databases, design theory and calculations, A-E interactive design processes, professional responsibilities and project execution plans described above.

9. RESEARCH : INTEGRATION OF BUILDING DESIGN WITH THE BUILDING LIFE-CYCLE

Architectural- Engineering (A-E) Design Integration

The A-E design segment is the originating source of the information developed for a building project that is ultimately distributed to the other industry segments of the building life-cycle. A-E design quality can reduce the life-cycle cost of the building with lower first cost and efficient building operation. Increasing the design component of the total project cost can decrease the building life-cycle cost. Inter-professional communication and project coordination during the A-E design phase is, therefore, a critical component of the total building life-cycle system and it will be emphasized during the initial phases of this research project.

The objectives for developing A-E design systems today are usually intended to satisfy the needs of A-E design firms in serving their clients. They do not look beyond design so that information databases from design can be automatically transmitted to and used by the manufacturing, construction and operation segments of the building life-cycle. Presently this information transfer tends to be manual through construction bid documents, and the building model is redeveloped at each of the subsequent phases.

Design - Construction Integration

The information flow process must maintain the continuity of the architectural engineering design process through the construction phase. The "design-construct" process would be more efficient and reliable if construction planning, cost estimating and management were integral parts of the design process. Design computer programs can be extended to produce construction plans, schedules and cost estimates.

Design-Equipment/Product Selection Integration

In order to make A-E design systems and procedures effective, they have to be interfaced and integrated with product catalogs and product selection programs of several alternative manufacturers of the same product type. In the case of M-E products, the issue of using test data instead of the performance data published in catalogs (interpolated and extrapolated from test data) must also be considered. Test data is generally considered proprietary information by some product manufacturers, and a mechanism for accessing this information without compromising its confidentiality has to be developed.

The use of proprietary product test information in developing automated building design systems poses some special problems for this interface segment of the life-cycle. For any given product category there are multiple manufacturers of that type of product. There also exists variations of the product type that can provide the same end results in terms of overall building performance. Design programs have to select from the catalogs of alternative manufacturers for the same type of equipment or be able to interact with the equipment selection programs of alternative manufacturers. This has to be accomplished through data exchange standards.

Design-Equipment/Product Supplier Integration

Construction drawings generated by automated systems in the design office are presently issued to the contractor and product/supplier sub-contractors on paper. The contractor then uses a digitizer or scanner to convert the "paper" drawings back to "electronic" drawings from which shop drawings are developed. Computerized shop drawings are next returned to the design office on paper for their review and approval. The approved paper shop drawings are scanned back into the computer and are used by numerical control machines to manufacture the equipment. For example, the use of plasma cutters to manufacture ductwork.

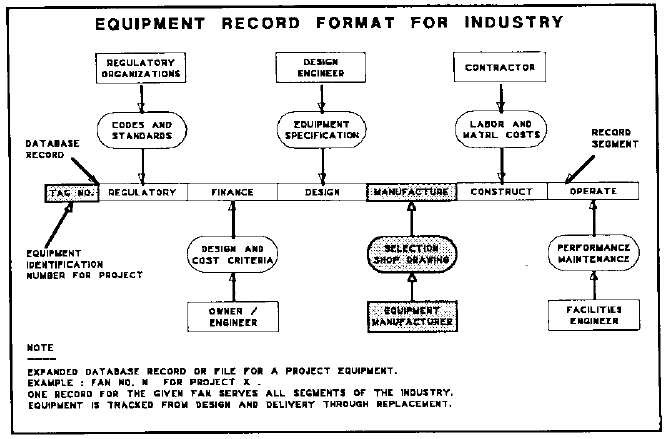

Although most products are mass produced in manufacturing plants based on estimated demand (some are custom ordered for a building project), an equipment such as a pump receives an official identity when the design engineer specifies it for a building, and the contractor purchases and installs it. The facilities engineer is responsible for maintaining the equipment.

A well defined design model can be directly integrated or interfaced with the order entry, numerical control systems (production plans), and transportation models of product suppliers. The process model must produce a smoother transition from design to product installation, and it must track a product item from the time it is specified by the design engineer, until it is scrapped or replaced by the facilities engineer.

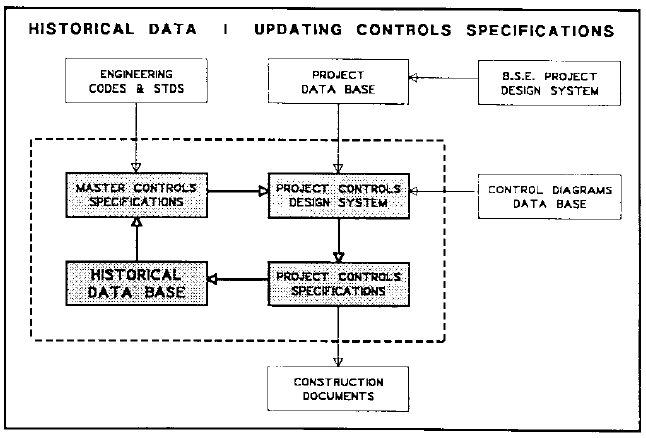

Design - Controls/Operation Integration

This information exchange interface has not received much attention in the building industry. The mechanical-electrical design engineer influences the operations phase of the building life-cycle by specifying the controls systems and the sequence of operations for the building project. A building automation/controls model is a detailed mechanical-electrical engineering design model in operation. This project will investigate the possibility of maintaining the integrity and continuity of the flow of information from design through operation.

Information flow from the building design team to the building operations or facilities management team is presently a one-way process. Computerized building management and control systems generate day to day information about the equipment and systems developed by the design team. This information should be transferred back to the design team so that it can be used to improve future designs. Since there is a considerable amount of information generated by building management systems, this information must be statistically analyzed, screened, condensed and converted into a standard format before it is returned to the design systems.

10. RESEARCH : ORGANIZATIONAL STRUCTURE AND INFORMATION COMMUNICATION

Organizational Realignment and Professional Responsibilities

The last decade produced computer imitations of manual procedures. The next decade should produce a re-definition of the industry structure and a re-programming of the building processes that will result in more efficient use of the computer. This project will study professional and organizational structures and alignments that makes the best use of automation and telecommunication technologies. There are two features inherent to on-going computer systems development that will produce changes in the organizational alignment of the building industry and also on the process of developing and operating a building.

The first is the continuous expansion of the scope of existing software applications (black boxes) and the continuous increase in the number of new applications to replace manual procedures that never used the computer before. The second is the cumulative effect of software development on the industry. New architects and engineers entering the AEC industry work from the current technological status of AEC software.

It is not necessary to have an in depth knowledge of the internal technical details of the software. Because of the "black box" and "cumulative knowledge and experience" features of computer software development, the organizational alignment of the building industry and the roles of building professionals in the industry must change continuously in the future. Educational systems must constantly adapt to these changes.

Information Coordination, Communication and Modification

Timely and effective communication between the various professionals working within the several independent organizations that make up the building project team will increase the efficiency of the building process, prevent costly errors and reduce the cost of the project. Responding to, and acting on communicated information is still the responsibility of the individuals on the building project team, and there are no standardized master plans for communication and reaction, that are used on building projects today.

This project will investigate the communication and response processes in the building industry by incorporating both manual and automated procedures into the building life-cycle information flow model. The emphasis will be on reaction (ensuring that there is a response), manual and automated, to communicated information. The building life-cycle model must be dynamic so that a specialized module will automatically reanalyze and readjust to the changes and new information that it receives from other modules and report its own reaction to the other modules in the project system that are affected. The modules assembled together to make up the project system must function like a single living organism.

11. RESEARCH : METHODOLOGIES AND PROCEDURES

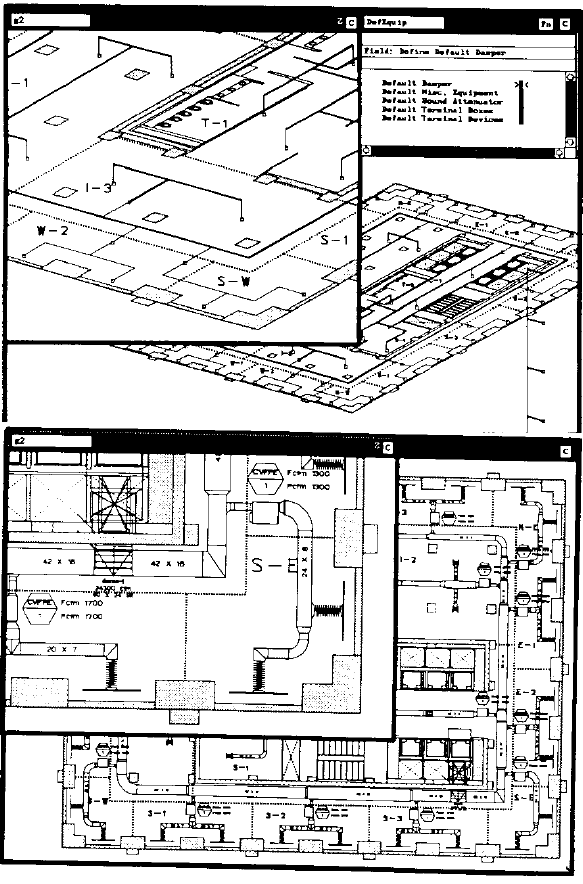

The following topics for study and development are provided in this proposal as examples only. These topics are extracted from the plans developed at Skidmore, Owings & Merrill (SOM) in 1990 to expand the M-E systems of the IBM Architecture & Engineering Series. These topics will be reviewed and redeveloped by the project team (AEC firms and universities) during the first three months of the project.

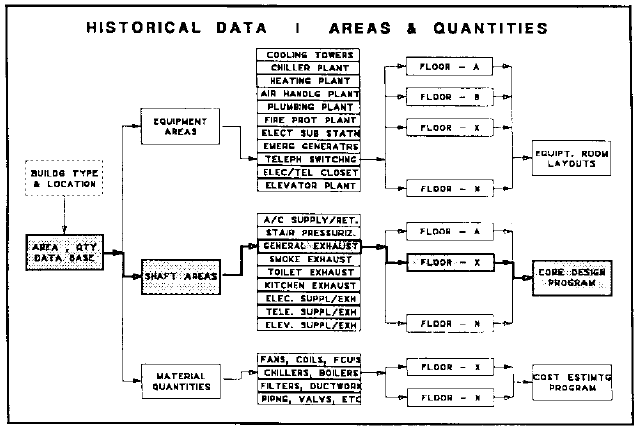

Preliminary Design using Historical Databases

This project will study preliminary design using historical databases, and recommend structures for a historical database system for mechanical equipment and systems used in buildings. Although the validity of historical information applies to the time period when it was developed, it can still play a very important role in preliminary design, preliminary cost estimating, and for checking and evaluating current design. The structure of historical data banks have to be pre-defined, so that information can be entered into the data bank when a building project is completed, and so that it can be retrieved and used in analyzing and developing new buildings.

The objective of a "historical database" is to capture the knowledge and experience of experts (experienced architects/engineers) and to save this information for future use. A-E design applications derived from historical information would be able to assist the less experienced architects and engineers in decision making during the preliminary conceptual stages of a project when information required for absolute decisions is not available.

Criteria Based Schematic Design using Architectural-Engineering Information Libraries

This project will investigate and recommend structures for M-E design databases consisting of design criteria, design rules, codes and standards. These databases together with historical databases can be used to design and estimate the cost of M-E systems based on criteria information before detailed architectural drawings and specifications are available.

In order to achieve inter-disciplinary building systems integration, the emphasis will first be on the objects such as the building, its elements and its equipment, and then by project phases and professional specialization. The information required to design A-E systems will be organized into reference libraries and project libraries.

Reference library information is for the use of all projects. Reference libraries include historical information, engineering data, codes and standards, design rules and procedures, equipment performance data, graphic symbols of engineering elements, graphic database of standard details, master specifications, cost data.

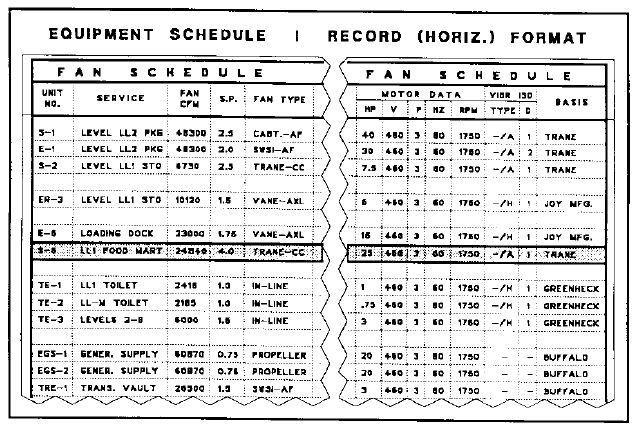

Project library information is specific to the project (includes dimensional data) and it can be developed by customizing reference library information. Project libraries include application system input, engineering reports, construction drawings, equipment performance schedules, project specifications, cost estimates.

Organizing M-E Design on the Basis of Similar Processes

The boundaries of an integrated design system include architectural, structural, electrical and other design disciplines besides mechanical. Mechanical systems are closely associated with electrical systems, since they require (electrical) power and (electronic) controls in order to operate. The mechanical-electrical (M-E) design system will be organized on the basis of similar objects and processes, instead of dividing them by professions (HVAC, Plumbing, Fire Protection, Controls, Electrical Power, Lighting, etc.) established in the past. The processes include:

(a) an "information system" (integrated across the design disciplines) containing design data from handbooks, catalogs and other reference sources

(b) a "design criteria system" that includes performance requirements and design codes and standards for different types of buildings, spaces and systems

(c) an "evaluation system" to analyze the building environment to maintain the required conditions

(d) an "equipment system" to treat the building environment and to maintain the required conditions

(e) a "distribution system" to move energy and matter in various forms from a generating source to the equipment systems, and to return and extract used, unused, and waste products for recycling and disposal

(f) an "operating system" (building management and controls) to make the total dynamic ME system work

(g) a "communication system" (drawings, schedules, specifications) to transmit the design information to product vendors, contractors and facilities engineers.

Energy Efficiency in Building Design

Since the emphasis is on mechanical-electrical products and systems, this project will consider energy efficient building design, when developing the design component of the information flow model. It will consider the application of

(a) the major building energy analysis programs in design,

(b) the major M-E software design systems,

(c) M-E product selection software systems in design,

(d) building control software systems in design, and

(e) and constraints set by design systems such as fire and life-safety. Decisions made by all the A-E design disciplines (architectural, facilities planning, structural, mechanical, electrical) affect the energy efficiency.

Design-Construction as a Manufacturing (Industrial Engineering) Process

All large and complex buildings are developed today as unique products. In the future, the computer will be able to generate several alternative designs for a building project based on publicly available information databases, client criteria and constraints, and rules for designing different types of buildings.

Using a well defined information highway system (and despite the fragmented organizational structure of the building industry today) computer-based mass production assembly line techniques used in manufacturing today can be applied to building design and construction in the future, without affecting the aesthetic uniqueness of each building. This project will evaluate the use of industrial engineering, quality control and cost control methods in developing the building systems.

12. CURRENT RELATED RESEARCH WORK (Preliminary List)

This project will collaborate with other research groups that are involved in developing advanced automation technologies that can be used to improve the efficiency of the information process model. Documenting the work of these centers and incorporating the work into the educational products will be one of the major tasks of this project. The following is a preliminary list of related work currently being done at research centers.

Industry Alliance for Interoperability (IAI)

The IAI is incorporated as a non-profit organization with open membership internationally. Its objective is to enable interoperability between computer software serving the architectural, engineering, construction and facilities management (AEC-FM) industry. The IAI comprises leading companies who are committed to working together to define an information model for the AEC-FM industry which will establish a basis for interoperable software applications between disciplines throughout the building life-cycle.

The goal of IAI is to promote a new global data exchange standards for information sharing. The IAI is working closely with the "STEP" international community so that work being done by "STEP" AEC committees (and the Building Construction Core Model project specifically) is coordinated and shared to ensure synergy of information definition. Autodesk as the leading AEC CAD vendor (AutoCAD) is a founding member of the IAI and has committed to implementing the IAI information model via Industry Foundation Classes (IFC). The IAI information model will be published for use throughout the industry and will therefore be available to this project. The scope of this project will require the IAI information model to be expanded to include greater levels of application specific detail for M-E systems

Construction Engineering Research Laboratories (CERL), U.S. Army Corps of Engineers

This work is being performed by the Concurrent Engineering Team at the US Army Construction Engineering Research Laboratories (CERL). It involves the application of "Integrated Product and Process Development (IPPD)" techniques to the design and construction of facilities.

The test bed scenario was developed to investigate (a) how the new Information Processing (IP) techniques require changes in the current process of facility delivery, and (b) how IP can be used to model the process as well as the product. The test bed uses a virtual teaming architecture centered upon an object-oriented representation provided by the Agent Collaboration (ACE) and Design++.

The information exchange between these two systems is accomplished using an approach called the Virtual Workspace Language (VWL) which incorporates Knowledge Interchange Format (KIF) and Knowledge Query Manipulation Language (KQML). Product libraries have been developed to provide a shared representation in which all participants can create objects and communicate information.

These libraries contain both product information and process information to allow coordination and management of complex projects. Agents which used this shared representation to exchange product and process information have been developed for project management, architectural-engineering design, construction, and operation and maintenance.

Lawrence-Berkeley Laboratory (LBL), University of California-Berkeley

"Power DOE" is a new building energy simulation program that is being jointly developed by the Electric Power Research Institute and the US Department of Energy (DOE). It is based on the DOE-2 program which has been the premier standard in the building industry for over 15 years in analyzing the performance and economics of new and existing buildings, and their equipment and systems.

DOE-2 has been incorporated as a program module into the IBM A&ES system. PowerDOE has a graphical user interface running under Microsoft Windows. The "Environmental Design Assistant (EDA)" program linked to PowerDOE can assist the user in making energy related design decisions. PowerDOE has an open architecture to encourage third party development of specialized performance analysis modules that can be attached to the core program. Lawrence Berkeley Laboratory is currently working on developing "An Energy Design Tool for the Initial, Schematic Phases of Building Design". This project is being funded by the California Institute for Energy Efficiency (CIEE) and the US Department of Energy (DOE). The project involves developing a Case Studies Database (CSD) that will serve as the equivalent of an electronic magazine for buildings.

CSD will be designed to accommodate a large number of building data collected by Southern California Edison (SCE). The project will develop a Schematic Design Tool (SDT) that will allow building designers to address building parameters such as shape, orientation and number of floors, with feedback on energy performance.

Center for Integrated Facility Engineering (CIFE), Stanford University

The work at CIFE includes the development of a broad range of technologies (based on Artificial Intelligence, Robotics, etc.) that can be (and have been) applied to the building sciences. A specific current project at CIFE that has a direct bearing on this project is "The Integration of CAD and Energy Analysis Software for Building Design".

This is a collaborative effort with Lawrence Berkeley Laboratory (LBL) and is part of LBL's "PowerDOE" and "Energy Design Tool for the Initial, Schematic Phases of Building Design" projects. The CIFE project will explore means by which a building design represented in a typical CAD system (AutoCAD has been selected as the initial CAD modeler) can be integrated with LBL's "PowerDOE" and "Environmental Design Assistant" software to obtain building simulation and advice regarding improvement of the building's energy and cost performance.

Computer Models for the Building Industry in Europe (COMBINE)

The COMBINE (Computer Models for the Building Industry in Europe) group in Europe headed by Professor Godfried Augenbroe of the Delft University of Technology in the Netherlands includes the Building Research Establishment in the United Kingdom, Centre Scientifique et Technique du Batiment in France, Fraunhofer Institut fur Bauphysik in Germany, and other national building research centers and major universities in the EEC nations of Europe.

This group is actively involved with the ISO/STEP program in defining a general product data model that is specifically tailored for buildings. COMBINE-1 project built a prototype of such a model, using industry standards defined in the pre-release documents, and demonstrated that it could be used to link building design programs together by interfacing six of them to the model.

COMBINE-2 project is aimed at using the technology developed in the first project to produce a working set of integrated tools based around a product model, that can be installed and field tested in several engineering and architectural consultancies.

Automated Procedures for Engineering Consultants (APEC) : CABDS Project

CABDS (Computer-Aided-Building-Design-System) is an endeavor of the APEC/Industry Partnership, a non profit organization. CABDS permits HVAC design and analysis programs and manufacturers equipment selection programs to exchange data with each other and with CAD systems. The data exchange is made via a relational database (until objects become more mature) using standard tables / fields that are established by engineers and manufacturers representing various areas of applications.

As applications and their related tables / fields are developed, the schema for maintaining the relationship between tables is developed. There is currently available a CABDS User's Version for networks and a CABDS User's Version for stand alone computers that allow users to control the applications for exchanging data and for building and maintaining the database. A Software Development Tool Kit permits software developers to write new or modify existing programs to be CABDS compatible.

Computer Integrated Construction Group, National Institute of Standards & Technology

Pacific Northwest Laboratory / Battelle Laboratories, Energy Sciences Division

Center for Building Performance and Diagnostics, Carnegie-Mellon University

Civil and Environmental Engineering Department at MIT : IESL and CCRE

13. PROJECT SCHEDULE

| Year | Administration | Research/Study Activity | Products |

| 1 | Contract agreements. Communication plans. Evaluation methods. Project anagement. Financial management. Progress & cost reports. Authorization, copyright reproduction and non-disclosure agreements. | Establish research project team commitments in work-hours, money and other resources. Develop 1-year and 5-year project execution plans showing time-line, project team responsibilities and deliverable products. Develop and document information sources, and information categories. Define, classify and organize products, objects, systems, attributes, database structures and formats. | Project Plan. Mechanical- Electrical Information System Progress Report. |

| 2 | Financial management. Progress & cost reports. | Mechanical-Electrical (M-E) systems design theory and process. The documentation will be suitable for Architectural-Engineering (A-E) courses at universities. The presentation will emphasize the use of design software, M-E products, integrated M-E systems and the sequence of A-E design as it occurs in practice.. | M-E Design Handbooks Application of Proprietary M-E Software to Design Progress Report. |

| 3 | Financial management. Progress & cost reports. | Organizational structures of project teams for different types of buildings. Professional and organizational responsibilities. Inter-professional and interorganizational communication. Information transfer/exchange from design through operation. Legal issues Project planning and coordination for different types of buildings. Project financing and building economics. | Project Planning and Management Handbooks Progress Report. |

| 4 | Financial management. Progress & cost reports. | Case studies showing the design, construction and operation of different types of buildings. Design will be emphasized. Building types will include offices, schools, hotels, retail and health care. | Handbook of Building Case Studies Progress Report. |

| 5 | Financial management. Progress & cost reports. | Review, revise and update the work of the first 4 years. Additional technical input will be provided by the AEC project team. | Updated Publications Final Report. |

14. MECHANICAL-ELECTRICAL DESIGN INTEGRATION: Figures

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

>

> |

|

|

|

|

|

|

|

|

|

|

|