Dear everyone

I am preparing energy models for office buildings in Poland for LEED using ASHRAE 90.1-2007. I think that my fan modelling approach is incorrect.

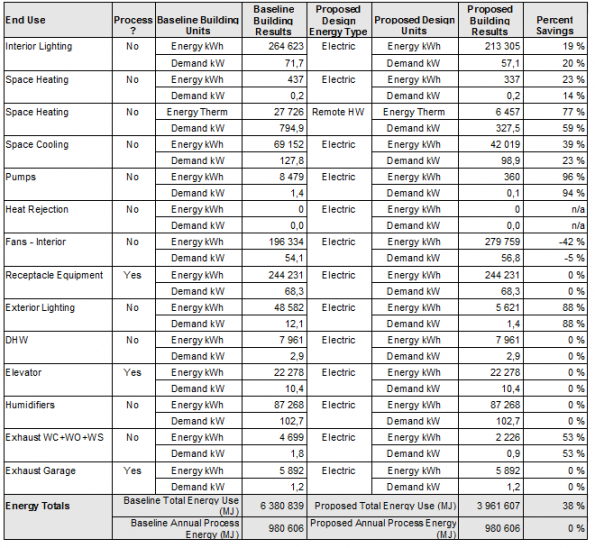

I compared my fan section results with other simulation report from Poland and other US. Their results show big savings in that section. My results shows about 40% loss in fan section.

I use HAP software. Total Baseline fan powers are calculated automatically by software and values are compatible with those calculated using fan calculator ( metodology ASHRAE 90.1.2007). For calculation purpose I use max supply air value and allowed pressure drop which is 1.4 w.c. inch (0.9 MERV filter and 0.5 ducted return)

I assign total power into supply section.

In proposed section fans are modeled as they are in technical documents. I model supply and return fans using SPF factors. Also in fan section fancoil`s fan are included, but even excluding them my project I has 10% loss in that section.

System type is System 5 with VAV which should cause savings because of more supply air than the CAV in Proposed.

In my opinion there is something wrong with SPF factors.

##################

For Baseline total SPF factor ( supply + return) for System 5 in my case is equal to 2.63 kW/m3/s = 1,24 W/cfm

For Proposed system which correspond to Baseline`s System in technicals I have a sum of 3.6 (2.1 supply +1.6 return) kW/m3/s = 1.7 W/cfm which is much more than Baseline.

Manufacturer said this value is correct. It was calculated using pessure drop based on designed ventilation duct.

#################

Other manufacturer specifications has similar SFP factors. Only for 1-store building for which I prepare my energy model this factor is lower than baseline`s one.

SFP factor must be included in technical documents according to Polish Minister ordinande, but this documment doesn`t provide a metodology of calculation.

In that ordinance stays that maximum supply fan power should be no more than 1.9 kW/m3/s (0.897W/cfm). Our fans exceeds this value. Maybe it`s because this ordinance doesn`t give us strict metodology.

Manufacturer said that some companies calculate this factor using different metodology and they got lower SFP but that value is not compatible with reality.

I don`t think that these fans are inefficient. This problem costs about 3-4 LEED points in every model.

So I wanted to know how to model them properly to provide savings in fan section.

Can anybody help with this?