HVAC - What is a Cooling Design Day?

Design Days are here!

Maybe you already know about Design Days, but did you know that Energy Modeling was basically invented to determine the design day, and the design hour?

What is a Cooling Design Day and why is it important?

The Cooling Design Day is effectively the "worst case" day for your air conditioning loads. The "worst case" hour of this day determines equipment capacity, fan sizes, and subsequently duct sizes. This largely impacts first cost. The Design Hour also impacts peak KW demand which often has a huge impact on the utility bill.

When is the Design hour?

A common rule of thumb is that the design hour occurs during July at 15:00. The summer months are common but a peak in any month is possible especially in warmer climates where the solar angle fluctuates more than the ambient conditions.

I pulled up a random file and plotted the design loads. The "rule" for July doesn't hold. In fact, September shows a higher peak than July!

Why is my Cooling Design Day in December (or October, November, January etc)?

You are expecting a Cooling Design Day to occur sometime between June and August, but yet you simulate and find that December has your peak design. The model must be GIGO, right? Well, maybe, but the first thing you should consider is whether or not you are in Climate zones 1-3. In warmer climates, the solar angle can often influence the design day more than the ambient conditions because the solar angle fluctuates to a greater degree. At lower latitudes, the summer solar angle results in the sun hitting the roof, but in the winter the solar angle is lower and the sunlight enters the windows, producing a very high solar heat gain, which can easily offset the more temperate ambient conditions. It's common to have a cooling design day in the winter months, especially if you have a lot of southern facing fenestration (in the Northern hemisphere of course).

What are the predominate conditions that effect the design day?

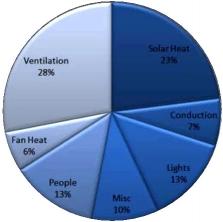

Most people consider the dry bulb temperature to influence the design day the most. This is flawed thinking. Heat transfer (UA Delta T) is often only 10% of the peak design load. These are common factors and common "weight" of the total cooling load for a typical building.

- Solar Heat Gain (20-30% but can jump as high as 70% or more)

- Ventilation (20-30%)

- UAΔT Conduction (5-10%)

- People, Lights, and Plug Loads (25-35%)

- Fan heat (3-8%)

Here's a snapshot of a real model's peak cooling loads by category:

It should be noted that People, Lights, and Plug loads will typically have a consistent peak value in 12 month occupancy. Fan heat would be consistent as well. Thus, the typical variables that decide the cooling design are the Ambient and solar conditions, with the two largest factors being solar heat gain, and ventilation.

Do not forget that the ventilation load is based on the ENTHALPY - not just the dry bulb but the wet bulb. In temperate climates, the wet bulb can stay relatively constant and therefore the predominating factor is the solar heat gain, which is largely influenced by the angle and inclination of the sun. Thus, the direction of fenestration can align differently and cause a peak at virtually anytime.

My cooling design hour occurs at night. Why?

If your cooling design hour occurs at night and you don't have a clue why, it's likely that you have a terrible energy model. However, in some buildings, a peak cooling hour at night is possible most likely due to a variable in people, lights, and plug loads, which of course would also increase the ventilation load.