A BEM Calibration method on steroids

BEM Calibration AI Method

Co-Authored with Bob Fassbender

Here's a video excerpt of an Energyplus model that has been trained to run in AI and can now run instantly along 4 variables

(note, this uses 4 different variables than those mentioned but the principle is the same)

What does this have to do with Calibration?

I posted a question on LinkedIn some time ago surveying modelers on what some of their biggest time sinks are when calibrating an energy model. Most every response involved getting accurate data. Not one person mentioned something that I thought would be very obvious: simulation time.

Whenever we are calibrating and we receive updated information, we have to iterate the calibration by one variable at a time, and then add the next variable and iterate. Moreover, we almost never obtain perfectly accurate data, and have to make educated guesses in the form of iterations.

PROBLEM: This takes an extreme amount of time

When iterating a simulation, there is a factorial effect based on the number of unknowns. The time required is exponential. For example, if we have 1 variable with 5 possible values, that’s 5 simulations, but if we have 4 variables with 5 possible values each, that’s 625 possible iterations. Usually, we have more variables with more possible values than that, and that’s usually a best-case calibration. In that example, a 10-minute simulation time, results in over 100 hours of simulation time, not including time editing the model and viewing results. Even if we automate it, that’s a long time and it’s expensive.

Bring on the Machines - EnergyPlus Bots

Quite some time ago, I was introduced to a machine learning application using EnergyPlus. I planned on using it to improve calibration, but the lack of a user manual prevented me from doing so.

What is Machine Learning in EnergyPlus?

For those of you who don’t know, machine learning takes a set of complicated algorithms, such as an EnergyPlus engine and effectively creates a new engine that is only readable by the machine. This can be done with any simulation, there's even a famous example where it was done to simulate the universe - which reduced the simulation time from weeks to about .1 seconds.

Keeping the focus on EnergyPlus, in the above example, our model takes 10 minutes to simulate. We can select which variables we want to change (in this case 4 variables) and then train the model. In most cases, we can train the model by automatically running it 50 times, randomly changing the 4 variables each time. This of course is done in the cloud, so the models can run simultaneously so it can be completed faster. After that, we have a “trained” AI model.

Once trained, the machine essentially creates its own “EnergyPlus engine” which is a a form of AI that can calculate results within a fraction of a second, in lieu of 10 minutes. The catch is that it only works for that specific model and for the trained variables, but it is impressive.

As I demonstrated in our online calibration course and spreadsheet that I developed some years ago, most calibrations can be pinned down to a few unknown variables. Therefore, it is prudent to take a model, train it for those variables, and set the machine learning

The example at the top of the page was done at Buildsim.io and can be done by anyone with an account. There are other features aside from AI learning, but it is one of the simplest AI options available. Moreover, there was an option to add some code or a solver to the AI simulation. For example, we could ask the AI to the following. Change the LPD, COP, Window NFRC, and U-value until the annual kWh is within X% of the actual data (or we could move the sliders manually as in the above video - noting that one of the outputs was total kWh). Along those lines we could include the total gas so that also matches the annual total. We could continue to add some equations to account for peak demand and ultimately try to refine the model month by month. As noted, we can allow for limits on the variables so that the solution is within reason (so we don't get a solution where the LPD is 4 watts per square foot)

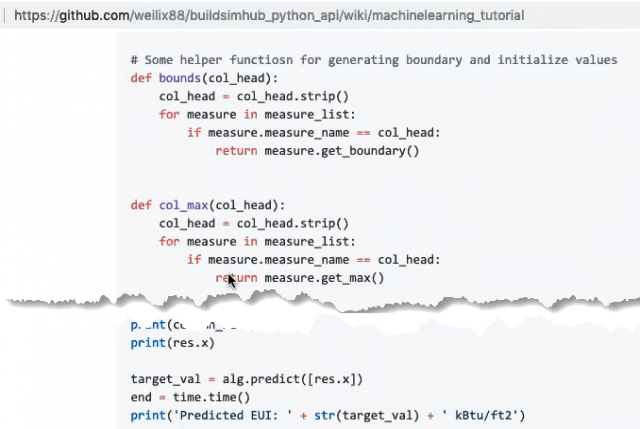

Buildsim.io has an example of some python code that optimized EUI based on the upfront cost. It looked like this:

Essentially, you could run 10,000 simulation combinations within a few minutes and solve any set of equations. While I will note that isn’t an end all solution, it’s better than any alternative I can think of. A good analyst would understand it’s highly likely that the machine would be able to come up with multiple solutions. However, given the nature of simulations, we could get a very good idea of the “unknown” inputs and ultimately achieve a quality calibration.

First step is proof of concept

If I had to guess, I’d wager some companies have already mapped out their own AI strategies through what's known as neural networks and are using this as a competitive edge.

For most of us, we don’t have the resources to do that and need a pre-mapped out machine learning interface. That’s ready and waiting at BuildSim.io. Any takers here? It wouldn't be a perfect "calibration" but it would be extremely useful. I’ve been holding out on this idea for some time, to maintain for my own competitive advantage or so that I could teach it in full, since most of you are salaried and way too lazy to do anything about it.

Given that I am busy and as I have not been able to find the time or manual to create a “solver” equation, I thought the most useful approach is to share the idea with the community, in hopes of finding advancement for us all

Alternatively, many people could sign up and BuildSim.io and put requests in for this feature. Start pressuring the developers for a simple set of solver equations. They were working on full calibration abilities and I suspect they got lost in the weeds.

In the idea proposed above, we won't have a "fully" calibrated building, but if we did our due diligence and set up all of the known schedules, this method would save tremendous amounts of simulation time, and can be combined with experience to get a very calibrated model.

FAQ: Why can we get multiple solutions?

Certain variables have similar impacts, but a change to cooling COP will impact the monthly profile differently than for example changing the lighting power (which would behave almost identically to changing the receptacles).

For example, when lighting power changes, every monthly bill increases. However, cooling months increase more than most months, while heating months decrease. It should be noted that a similar impact will happen for receptacle loads that is near indistinguishable from the lights. However, peak lighting should be more readily determined from a set of drawings

When glass parameters change, a similar effect will be seen. For example, an increased SHGC will raise cooling energy but lower heating energy. However, the net pattern will be much different than simply increasing the lighting power.

How Can I learn more about what variables to select?

There is a breakdown of variables in a calibration course that I wrote. Given that I wrote it some time ago, I should note that my ideas have proven successful, and therefore it adds to the credibility that this AI idea has merit. I'm not writing this to pat myself on the back, but rather to encourage confidence that my thought process was proven useful. The interesting part about this course is that all of the math was 100% deduced by me - even the coefficient of determination (which is cited in ASHRAE's calibration standard). Additionally, and also comically, some of my quotes in the course must have been convincing as I have seen parts of it quoted verbatim in various calibration requirements that I have worked on myself. (It's kind of odd when someone tells you that you made a mistake and need to meet a criterion that you yourself quoted verbatim as a sort of "off the cuff remark")

Given that, I would advocate that someone, especially with python skills, to dig into this AI method and then to please share it with the community. Or maybe someone has already done that and I am not aware of it.

The bots already control our lives more than we are aware. If you are reading this, bots probably guided you to it. That is not hyperbole. So why not take advantage of the same technology that has already become our overlord?

Pratibha Maloo

LinkedInPratibha Maloo, a data scientist with over a decade of experience in the tech sector, plays a key role in ensuring user-centric design by creating intuitive and engaging interfaces that optimize user experience on the platform. She also advises on integrating AI/ML models into the development of the Smart Energy Management Platform.